|

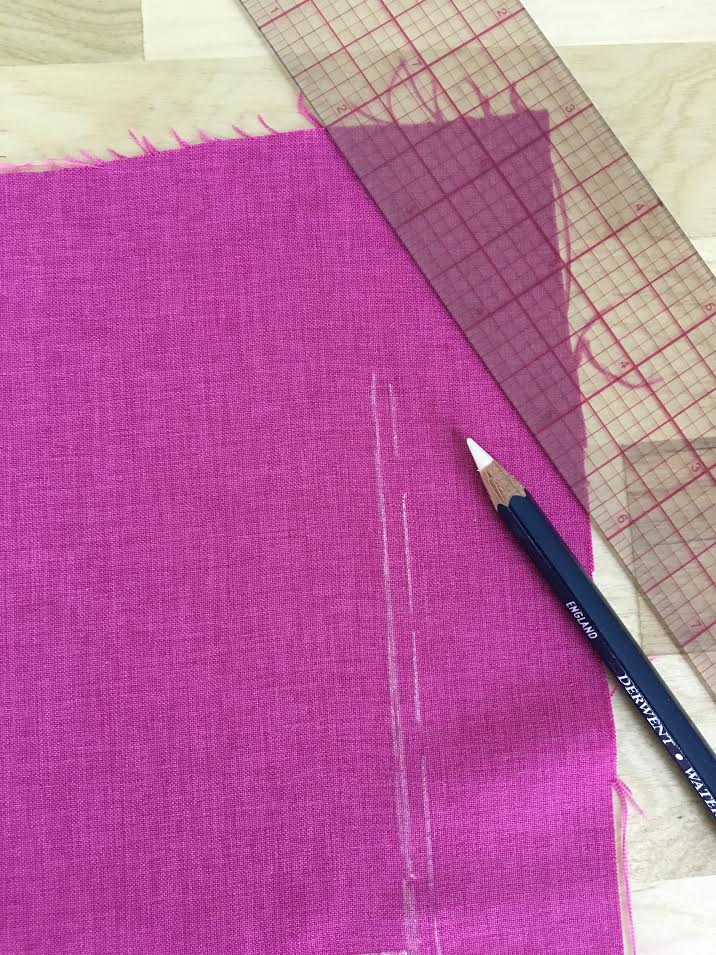

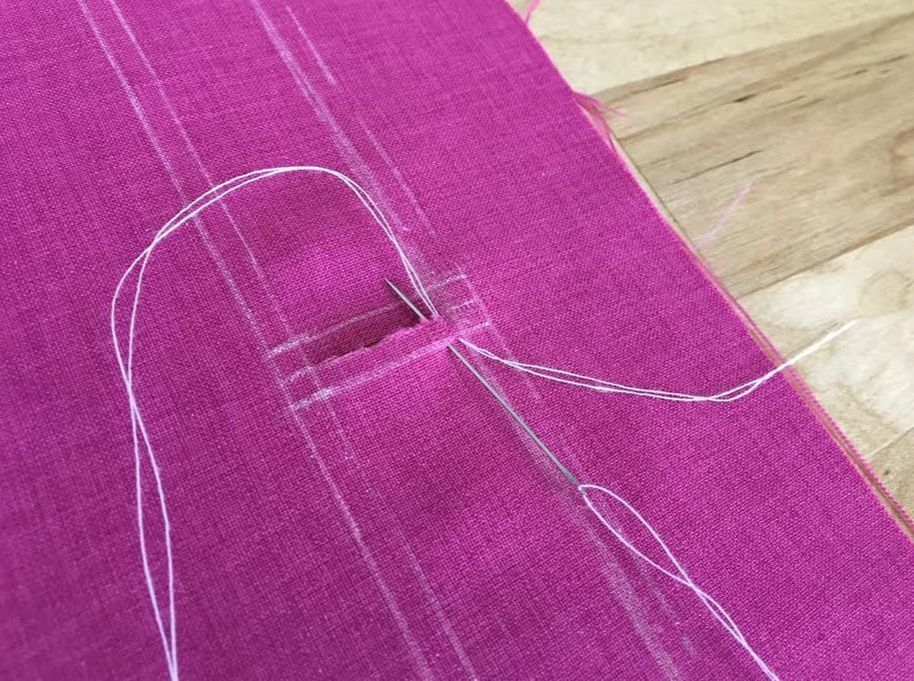

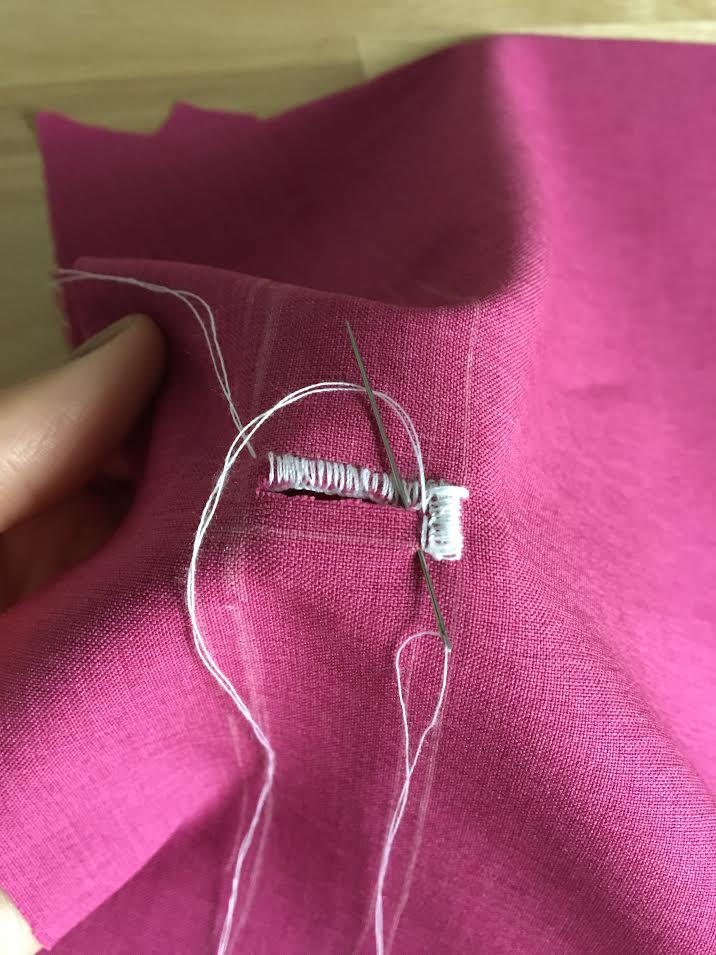

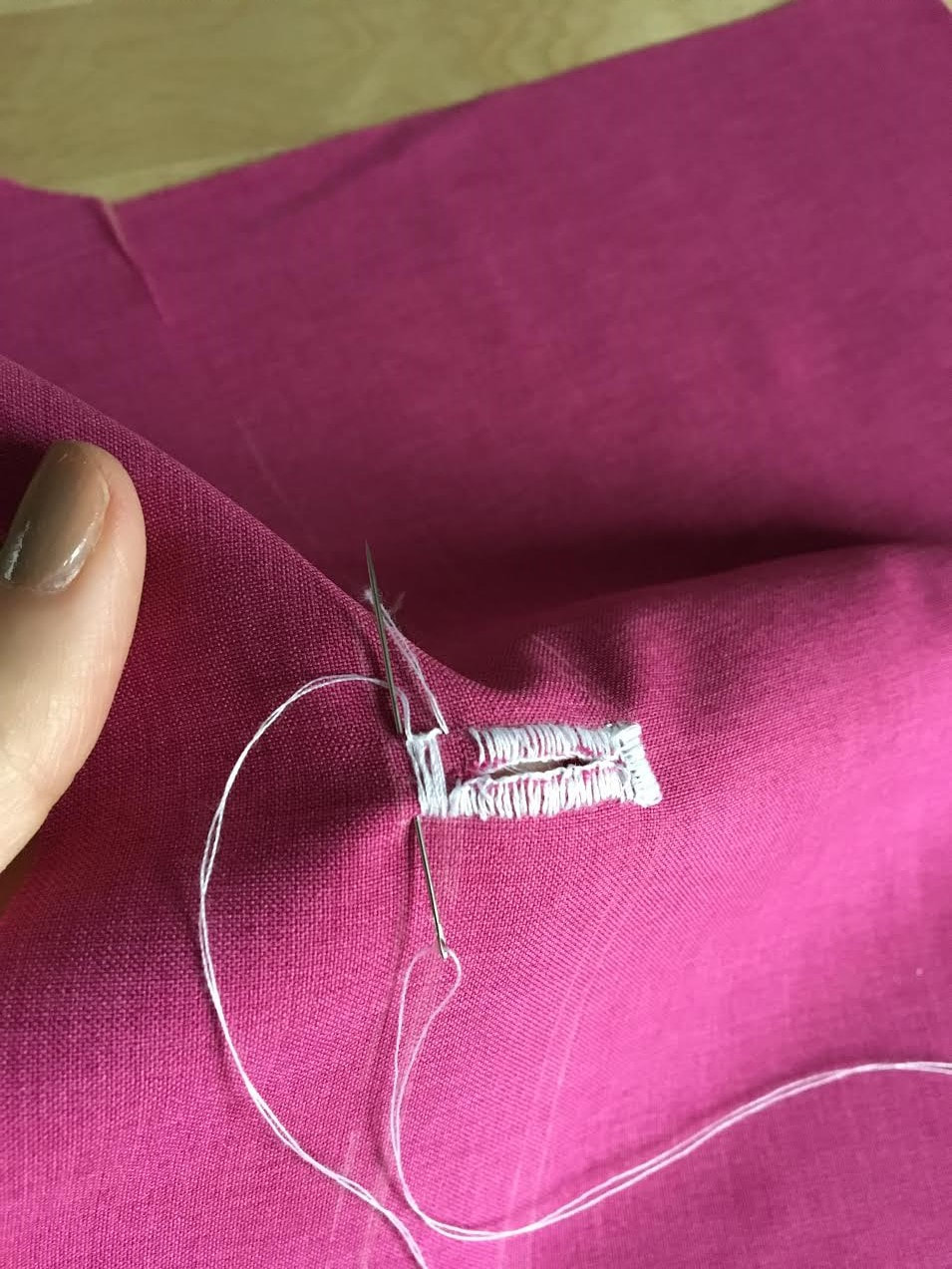

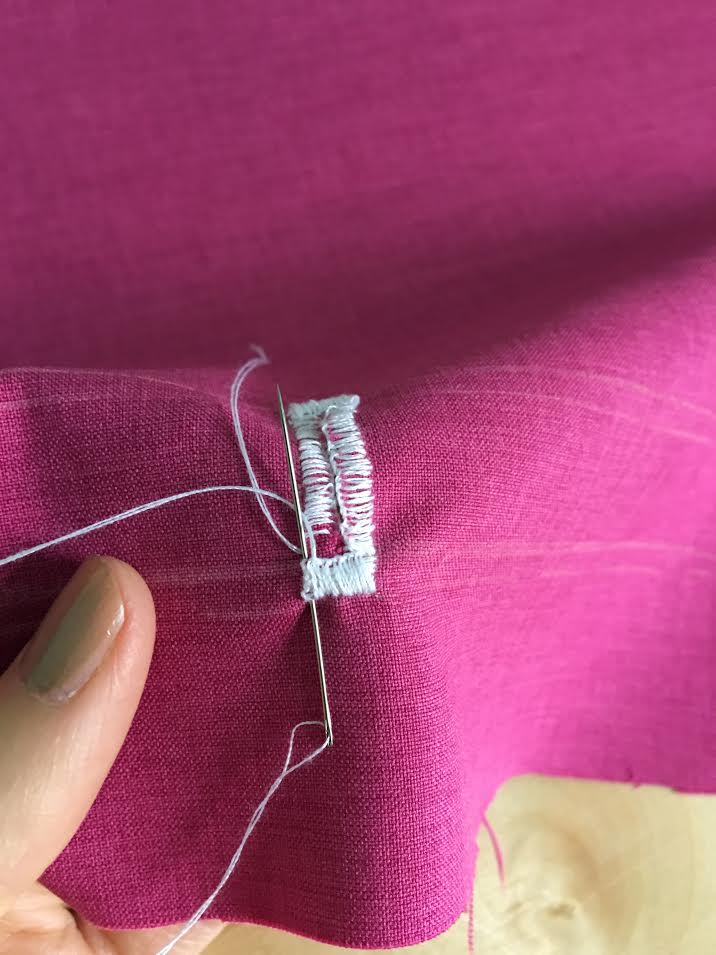

As a sewing beginner, you probably won't dive into sewing button closures straight away. However, at some point or another, a sewing project might call for the addition of a button closure. While buttons are a breeze to sew, buttonholes can be a bit more challenging, especially when it comes to their size and alignment. Conveniently, most home sewing machines offer a buttonhole setting. In the case your machine doesn't offer this option, or you feel a bit intimidated by sewing the buttonhole on your machine, it can always be constructed by hand. Sewing a hand-worked buttonhole will also help you understand a bit more about the structure, size and alignment of traditional button closures. In addition, a hand-worked buttonhole helps you practice a few very important hand stitches such as a blanket stitch and straight tack. While the opening slit of a machine-sewn buttonhole is cut using a seam ripper after the stitches have been applied, hand-sewn buttonholes require that the slit is carefully cut first, after which a dense blanket stitch is applied to clean finish its raw edges. Traditionally, there are two styles of hand-sewn (hand-worked) buttonhole finishes: A fanned buttonhole where one of the buttonhole side edges is sewn with circular stitches to resemble a fan, and a straight edge buttonhole where both edges look the same and are finished with straight tacks. Most commonly, fanned buttonholes are used on horizontal applications and often used with shank buttons due to their ability to fit into the fanned area better. Vise versa, straight edge buttonholes are used on vertical applications, providing a durable, identical finish on both top and bottom edges. While it is always a good idea to follow this traditional concept, it may be a bit tricky for sewing beginners to construct a fanned buttonhole. We recommend starting with a straight-edge style (which is much easier to sew) and using it on both horizontal and vertical applications until you can truly feel comfortable sewing good quality blanket stitches. Another important aspect to consider is the size/length of the stitches. This should be decided based on fabric type and garment design. Normally, the width of the buttonhole blanket stitches should fall between 1/16" to 1/8" depending on the thickness and structure of the fabric, or how many layers of fabric you are sewing through. As a general rule: For fabrics that feature a looser weave, use a longer denser stitch. For fine fabrics that are thin and lightweight, shorter, dense stitches will work best. So now that you are familiar with some of the basic concepts associated with hand-worked buttonholes, let's get started with the sewing portion below. In this tutorial, we are using a 1/8" buttonhole stitch and white contrast thread in order to demonstrate the sewing steps clearer. Keep in mind however, that the thread color has to match the color of the fabric and you should choose the appropriate stitch length for your particular project based on the fabric and design at hand. How To Sew A Buttonhole By Hand 1. Draw a buttonhole diagram along the edge of the garment where the buttonholes will be placed. You might be tempted to skip this step, but as you'll see from the sewing steps below, having a temporarily drawn diagram on fabric will ensure that each buttonhole is spaced evenly (at the same distance) maintaining the same size throughout without the necessity to re-measure every buttonhole individually. To start with, draw two vertical lines using a water soluble pencil (or tailor's chalk) at 1/8" distance apart. This 1/8" distance will actually mark the side edge of the buttonhole and can be of a shorter or longer length depending on the size and style of the buttonhole (considering fabric type, of course). For the learning purpose of this tutorial, we'll start with 1/8", which is one of the larger stitch lengths. A little side note on the tools: It is highly recommended that you invest in an 18" clear plastic ruler marked down to 1/16th of an inch. This will make your life so much easier when it comes to drawing this diagram, also serving as an essential tool if you plan on making your own sewing patterns from scratch. This pattern-making ruler is available at most craft/fabric stores. If you don't have any tailor's chalk or a water soluble pencil, use a dry piece of soap- It works just as well and is extremely easy to remove once the buttonhole is completed. Want to learn more sewing hacks? check out this tutorial: 6 Sewing Hacks For The Creative Seamstress. 2. Next, draw a horizontal line, perpendicular to the vertical ones, measuring the length of the buttonhole opening. In this tutorial, the buttonhole opening is 3/4". By the way, you'll find that if you use the marked clear ruler shown above, keeping the lines perpendicular and accurately measured is quite easy to accomplish. If you are unsure regarding the size of the buttonhole opening, simply measure the button's diameter (or check the button packaging for noted size) and subtract 1/16" from this measurement. The new measurement (after the 1/16" subtraction) marks the length of the buttonhole. The reason for making the opening 1/16" shorter than the button diameter is to create a more stable connection between the button and buttonhole portion of the garment opening. In addition, buttonholes (especially those sewn by hand) stretch out over time, losing some of their structure during long term wear and care. Constructing the slit opening to be shorter in length will contribute to the buttonhole's long lasting functionality. 3. Mark the other side edge of the buttonhole using a vertical line parallel to the existing vertical lines at 3/4" apart (or whatever the buttonhole opening length is in your case). 4. Just as you did initially, mark another parallel line at 1/8" away form this newly added vertical line. Your diagram should now have the marked side edges of the buttonhole (vertical lines at 1/8" apart) and the horizontal opening of the buttonhole. Note: If you need to hand-sew a vertical buttonhole instead, follow the same steps described above, but reverse the vertical lines with the horizontal ones and vise versa. 5. Next, decide on the desired buttonhole lengthwise width. In other words, how thick (or thin) do you want the buttonhole stitches to be. Good practice is to follow the side edges, which in this case are 1/8". Following the side edge measurement will allow for more even, linear buttonholes. Using your clear ruler, measure up 1/8 inches from the buttonhole opening line (initial horizontal line) and add a horizontal parallel line at this distance. Next, add another parallel line at 1/8", this time at the bottom of the buttonhole opening line as shown above. The buttonhole diagram is now complete! You can add equal-distance buttonholes along the entire garment edge using this diagram's parallel, vertical lines. 6. Carefully cut the buttonhole opening accurately following the middle horizontal line. It can be a bit tricky to cut inside the buttonhole using a regular pair of scissors. To ensure that the opening is cut smoothly, make a small cut through the fabric layer, directly on the middle line, using a seam ripper. This will make it easier to insert the scissors thus allowing you to cut the opening of the buttonhole smoothly. Be very careful not to cut past the inner vertical lines. The actual opening of the buttonhole is marked by the middle horizontal line between the inner vertical lines. As you can see from the image above, the horizontal opening of the buttonhole is carefully cut between the two inner vertical lines. Since the 1/8" distance between the side vertical lines constitute the side edges of the buttonhole, you should be very careful not be cut through them. 7. Now that the buttonhole shape is marked and cut, it is ready to be stitched! Thread a hand sewing needle and insert it through the bottom horizontal line and out through the cut opening of the buttonhole as shown above. In this tutorial, the thread is doubled. This allows for thicker stitches while also getting the job done faster. If you choose to use double thread however, be very careful to keep the thread strands smooth as they can get twisted and tangled if not kept uniform in the stitching process. In this instance, a shorter thread length may be easier to work with. After inserting the thread, leave enough loose thread at the end so that you can lock the stitch once the buttonhole is complete. You can also whip stitch in place a few times at this stage in order to lock the thread in place from the start. Loop the thread around in a circular shape, and insert the needle through this loop such that the needle is positioned on top of the thread. This is called a blanket stitch and it is often used to clean finish fabric raw edges by hand. Carefully pull the thread through the loop, making sure to pull the two strands of thread uniformly such that they do not tangle and stay together smoothly. Be careful not to pull the stitch too tightly. Each blanket stitch should be aligned in a straight fashion, and be stable enough to enclose the edge of the buttonhole opening without wrinkling it or creating tension. 8. Repeat the blanket stitch process described above, making sure to insert the needle right next to the bottom of the preceding stitch directly on top the bottom horizontal line as shown above. The goal is to achieve dense, thick blanket stitches thus seeing as little of the fabric underneath as possible. Carefully pull the thread through the loop again, aligning it parallel to the preceding stitch. Remember not to pull the thread too tightly as this can destruct the buttonhole opening edge. 9. Continue applying the blanket stitches densely and evenly such that the bottom row of stitches is aligned in a smooth, straight line. The stitches should be aligned carefully next to one another to enclose the bottom raw edge of the buttonhole opening fully. Make sure as little of the fabric is visible underneath. The stitching should be dense but not so tight as to de-construct the buttonhole opening. 10. Continue stitching until the entire bottom edge of the buttonhole opening is complete. When you arrive at the side edge, insert the needle at the bottom horizontal line and all the way through the top horizontal line as shown above. Repeat the blanket stitch process by pulling the needle through the looped thread. Pull the thread gently and not too tightly. Apply longer blanket-like stitches one right next to the other from the bottom horizontal line to the top until the entire side length between the two vertical lines is complete. These stitches are called straight tacks. Keep you stitches as close to each other as possible for a dense, sewing machine-like finish. 11. For structure and durability purposes, the side edges of the buttonhole will need an extra layer of stitching. Once the vertical straight tacks have been applied, go back to the bottom edge of the buttonhole and insert the needle through the fabric such that the straight tacks are enclosed as shown. Apply another set of side-by-side blanket stitches enclosing the straight tacks as shown in the image above. Continue until you reach the very top outer edge of the buttonhole. This extra blanket stitch, applied perpendicular to the vertical straight tacks underneath, should allow for extra reinforcement and create a durable buttonhole structure. 12. To increase sewing comfort, turn the fabric/buttonhole upside down such that the top fabric raw edge is now at the bottom. Starting right next to the vertical straight tacks, insert blanket stitches as described above, through the marked horizontal line at the bottom and out through the slit opening of the buttonhole. Continue applying the blanket stitches close together such as to hide as much of the fabric underneath and enclose the raw edge of the buttonhole opening. 13. When you reach the other side edge, repeat the vertical straight tack stitching from the top horizontal line to the bottom. Again, make sure these stitches are applied densely and smoothly throughout. Fill in the entire surface between the two parallel vertical lines as shown. 14. Once the vertical straight tacks are applied, turn the fabric and insert the needle through the fabric, enclosing the straight tacks. As you did for the other side edge, apply blanket stitches right next to one another, in perpendicular relation to the vertical stitches underneath. This row of blanket stitches should basically hide the straight tacks underneath, providing durability and long term use. Once the second side edge is complete, continue stitching along the raw fabric edge until you arrive at the exact point where you started. In other words, make sure that if there is still an area not fully covered with blanket stitches, it is filled in to provide a uniform, professional finish. 15. Now that the buttonhole stitches are complete, all you have to do is prevent them from unraveling by locking the loose thread ends. Using the hand-sewing needle, move any visible loose threads to the wrong side of the buttonhole/garment as shown. On the wrong side, either hand-knot them together or whip stitch them in place (such that this is not visible on the face of the garment) thus preventing the blanket stitches from coming undone during wear and continuous wash cycles. The hand-worked buttonhole is now complete! If you would like a thicker, denser finish, you can apply a second layer of blanket stitches along the top and bottom edges of the buttonhole opening. Using the diagram method described above, you can easily sew multiple buttonholes at the same size and aligned evenly in relation to one another. Additionally, you can construct a variety of buttonhole styles and sizes by adjusting the diagram's measurements accordingly.

0 Comments

Leave a Reply. |

The Blog:A journey into our design process, sewing tutorials, fashion tips, and all the inspiring people and things we love. Doina AlexeiDesigner by trade and dressmaker at heart. I spend most of my days obsessing over new fabrics and daydreaming new ideas. Sadie

Executive Assistant & Client Relations Manager Archives

November 2019

Categories

All

|

-

Sewing Tutorials

-

Basics

>

- Aligning Pattern Grainlines To Fabric

- Preparing Fabrics For Sewing

- Pinning Sewing Patterns To Fabric

- Placing Sewing Patterns On Fabric For Cutting

- Rotary Cutters or Fabric Scissors?

- Cutting The Sewing Patterns

- What Are Notches And How To Use Them In The Sewing Process

- Transferring Notches From Pattern To Fabric

- Transferring Seamlines to Fabric

- Staystitching

- Backstitching: A Complete Guide

- Hand Basting: A Complete Guide

- Sewing Continuous Bias Binding

- Darts >

-

Sewing Seams

>

- The Basics Of Seams And Seam Allowance

- How To Sew A Straight Seam

- Sewing Curved Seams

- Sewing Corner Seams

- Trimming And Grading Seam Excess

- Notching/Clipping Seam Allowance for Tension Release

- Sewing Topstitched Seams

- Sewing Corded Seams

- Sewing A Slot Seam

- Sewing A Gathered Seam

- Sewing Bias Seams

- Sewing Seams With Ease

- Sewing Seams With Crossing Seamlines

- Sewing Unlike Fabric Seams

- How To Iron Seams: Ironing Tools And Conventions

- Sewing With Knit Fabrics

- Understanding Stitch Length And Tension

- Sewing Unique Fabric Seams

-

Seam Finishes

>

- Seam Finishing Techniques - Overview

- Applying A Pinked Seam Finish

- Applying A Bias Bound Seam Finish

- Serging And Zigzag Seam Finishes

- Sewing A Self-Bound Seam Finish

- Sewing A French Seam Finish

- Sewing A Hong Kong Seam Finish

- Sewing A Mock French Seam Finish

- Sewing A Turned-and-Stitched Seam Finish

- Sewing Overcast Hand-Applied Seam Finishes

- Sewing A Flat Felled Seam

- Sewing A Hairline Seam Finish

-

Hem Finishes

>

- Garment Hem Finishes: Overview

- Sewing A Double Fold Hem Finish

- Sewing A Single Fold Hem Finish

- Sewing Bound Hem Finishes

- Sewing An Exposed Double Layer Bound Hem

- Sewing A Folded-Up Bound Hem with Pre-folded Binding

- Sewing A Hong Kong Hem Finish

- Sewing A Band Hem Finish

- Sewing A Bias Faced Hem Finish

- Sewing A Twill Tape Hem Finish

- Sewing A Rolled Hem Finish

- Sewing A Shaped Hem Facing

- Using Fusible Hem Tape And Webbing

- Finishing A Lace Fabric Hem

- Finishing A Leather Hem

- Sewing Faced Hem Corners

- How To Finish Lining At The Hem

- Finishing Fabric Corners by Mitering >

- Interfacing A Hemline: Lined And Unlined Examples

-

Sewing Pockets

>

- Curved Patch Pocket With Flap

- Unlined Square Patch Pockets

- Lined Patch Pockets: Two Ways

- Extension On-Seam Pockets

- Separate On-Seam Pocket

- Front Hip Pockets

- Bound Double Welt Pocket

- Double Welt Pocket With Flap

- Self-Welt Pocket (Using Single Fabric Layer)

- Slanted Welt Pocket (Hand-Stitched)

- Faced Slash Pockets: Overview >

-

Sewing Zippers

>

- Sewing Zippers: General Information

- Sewing A Centered Zipper

- Sewing A Lapped Zipper

- Sewing An Invisible Zipper

- Sewing A Fly Front Zipper

- Sewing A Closed-End Exposed Zipper (No Seam)

- Sewing An Exposed Separating Zipper

- Sewing Hand Stitched Zipper Applications

- Sewing A Zipper Underlay

- Sewing A Placket-Enclosed Separating Zipper

- Sleeveless Finishes >

-

Neckline Finishes

>

- Sewing A Neck Shaped Facing

- Sewing An All-In-One Neck Facing

- Neck And Garment Opening Combination Facings >

- Sewing A Bias Faced Neckline Finish

- Sewing A Band Neckline Finish

- Bound Neckline Finishes: Overview >

- Sewing A Semi-Stretch Strip Band Neckline

- Ribbed Neck Band And Classic Turtleneck

- Decorative Neckline Finishes >

- Finishing Facing Edges >

-

Extras

>

- A Complete Guide on Interfacing

- Sewing Bound Spaghetti Straps

- Sewing Spaghetti Straps To A Faced Neckline

- Sewing Ruffles: Overview

- Patterning And Sewing A Circle Ruffle

- Sewing A Gathered Heading Ruffle

- Sewing Double Layer Gathered Ruffles

- Sewing A Gathered Ruffle Into A Seam

- Sewing A Gathered Ruffle To A Fabric Edge

- Sewing A Fabric Surface Slit

- Sewing A Slit Seam

- Hand-Applied Straight Stitches

- Hand-Applied Blind Stitches

- Hand-Applied Overedge Stitches

- Hand-Applied Tack Stitches

- Hand-Applied Decorative Stitches

-

Basics

>

- Custom Bridal

- Custom Apparel

- About

- Blog

Services |

Company |

|

RSS Feed

RSS Feed