A separate neck-front facing is perhaps the most commonly used style in dressmaking. It is considered a conventional finish for blazers, coast and jackets that feature a full front opening.

Sewing the separate facing version is similar to the extended one with the exception that the garment opening edges feature a stitched seamline instead of a fold.

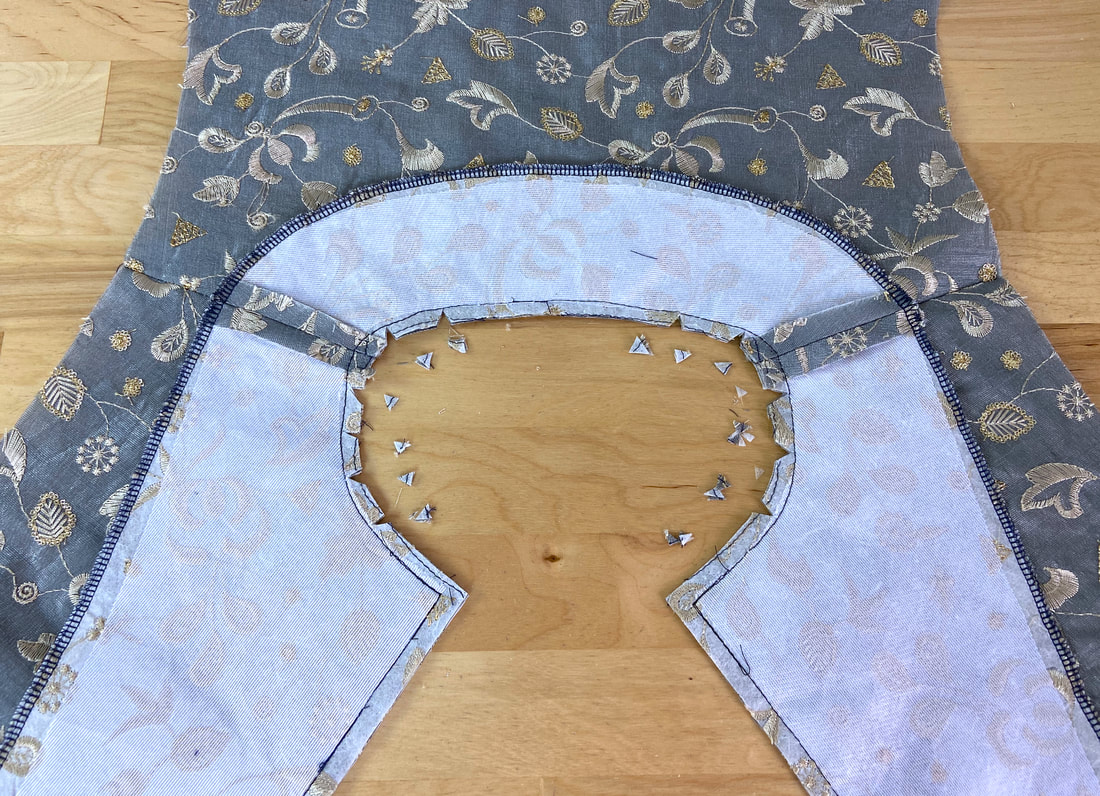

1. Before proceeding to sewing the seams, interface the wrong side of the garment or facing layer along the neckline and front opening portions as shown above. In this case, the facing pieces are interfaced.

Staystitch all the neckline edges at ¼” into the seam allowance.

Don't forget to staystitch the curved facing edges as well.

2. Match the facing shoulder seam edges with face sides touching and insert pins perpendicularly. Hand baste if needed.

3. Stitch the seams at the designated seam allowance (1/2” here).

Trim seam allowance down halfway (if needed), and iron the seam with the edges open as shown.

4. Apply the finish of your choice to the outer edge of the facing at the point. In this case, a simple serged finish is used.

Check out additional facing edge finishes here: Finishing Facing Edges

5. Repeat the shoulder matching and stitching process on the garment portions.

6. Keeping the garment on its right side, place the facing on top such that the fabric face sides are touching and all edges, including the garment opening, are aligned. Match and pin the garment and facing shoulder seams first, then the top corners of the garment opening. Next, insert pins horizontally along all garment opening and neckline edges as shown.

Note: if your garment opening has a separating zipper, the zipper should be stitched to the opening edges prior to the facing being attached.

7. Hand baste for extra stability, especially along the curved neckline edges.

8. Starting at the center back, machine stitch along the neckline until you arrive at the garment opening. Keep the top corner sharp by pivoting the stitch at a 90 degree angle.

Continue stitching down to the bottom of the garment.

9. Starting at the center back again, stitch along the other side of the facing, ending at the bottom of the other garment opening edge.

10. To reinforce each top transition corner, stitch over the existing stitch, extending 1” along both vertical and horizontal edges.

Once stitched, remove the hand basting (if any) using a seam ripper.

11. Trim all seam allowance edges to minimize unnecessary bulk. Grade the facing layer if necessary (always leave the garment seam allowance the longest).

12. Clip wedge notches into the curved edge of the seam allowance. Clip close to the stitching but be careful not to accidentally cut through it.

You do not need to notch the facing's vertical opening edge.

13. To minimize unwanted excess at the corner, clip the seam allowance diagonally across each corner as shown.

14. Turn the facing on its right side and iron the facing seam with the seam allowance layers pointing away from the garment. Do your best to iron at the corner.

15. Understitch at about 1/8” through the facing layer and seam allowance underneath. It is easiest to understitch the neckline first, then each individual opening edge separately.

16. Turn the finished facing to the inside of the garment and carefully iron the finished neckline and garment opening edges.

17. Match the facing and garment shoulder seams, and add a hand whipstitch or cross tack through the facing edge and garment seam allowance layers underneath. The tacks will keep the facing lying flat and prevent it from rolling outwards.