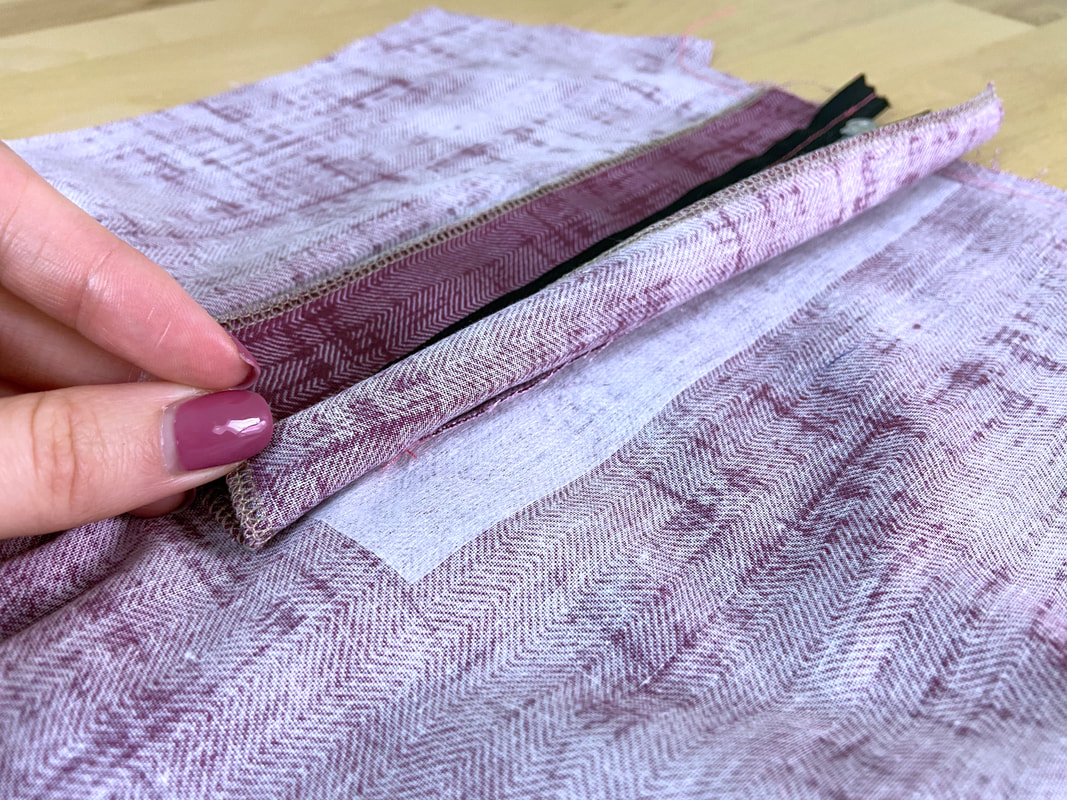

As opposed to conventional and invisible zipper applications, an exposed zipper with a closed end cannot be sewn into a seam.

This is one of the few times a zipper is inserted directly into the fabric surface. The reason? A closed-end exposed zipper requires a perfectly shaped rectangular cutout which simply cannot be built into a seam.

The technique for sewing a closed-end exposed zipper resembles that of sewing a welt pocket or a bound buttonhole. It may seem a bit complicated at first, but once you get the hang of it, you will love sewing this unique zipper application which is both decorative and highly functional.

Exposed closed-end zippers are most commonly used along neckline and waistline openings, usually positioned at the center back. On the garment, they are added where the exposed chain/coils create a desired design effect. A closed-end zipper style works well with other decorative finishes such as the addition of trims and contrast color fabric strips.

Anytime you cut into the fabric surface, whether you are inserting a zipper, pocket or a slit, the area where the fabric is cut should be reinforced with interfacing.

In the case of an exposed zipper, the cut should also be backed with a facing strip, known as a stay. Without this extra reinforcement, the fabric layer alone will not be durable enough to withstand the weight of the exposed zipper- it will sag, stretch the fabric out of shape, or come undone at the seams altogether.

When it comes to this unique zipper application, the best way to learn is from practice so let’s get started with the sewing steps below.

Inserting A Closed-End Exposed Zipper

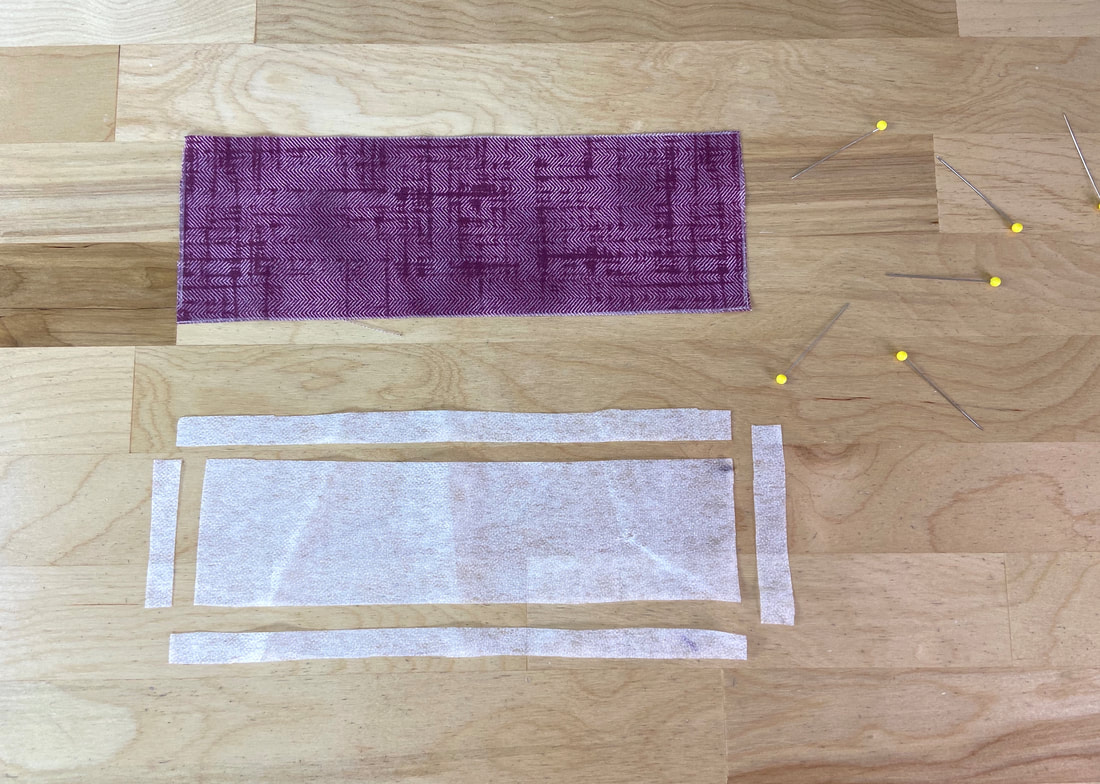

1. Cut out a strip of either matching fabric or one that provides more structure and desired color contrast. The strip should be 3"-4” wide and about 2” longer than the zipper length. It will serve as the zipper facing, or stay.

Although you won’t see this fabric portion on the right side of the completed garment, it does help to use fabric that provides a good mix both aesthetically and functionally.

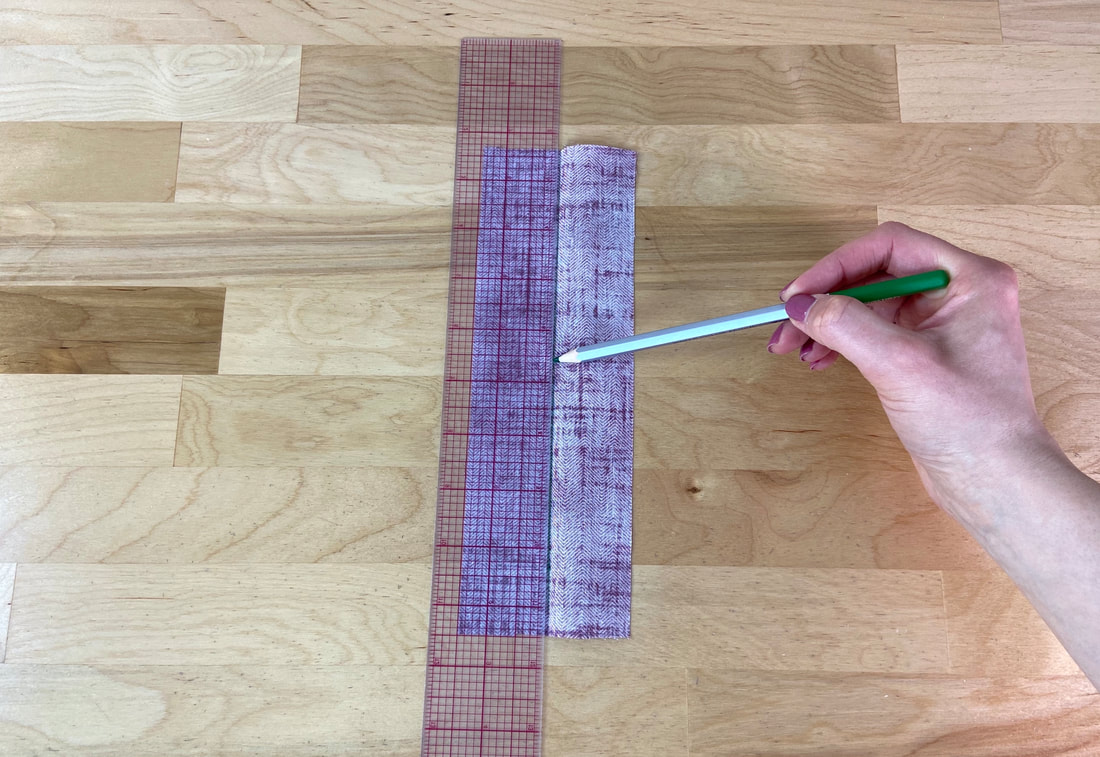

In this case, since the zipper is 7” long, the stay will be 3” wide and 9” long. Mark this rectangular shape directly on fabric using a ruler and tailor’s chalk (or fabric pencil) as shown. Cut the rectangle out.

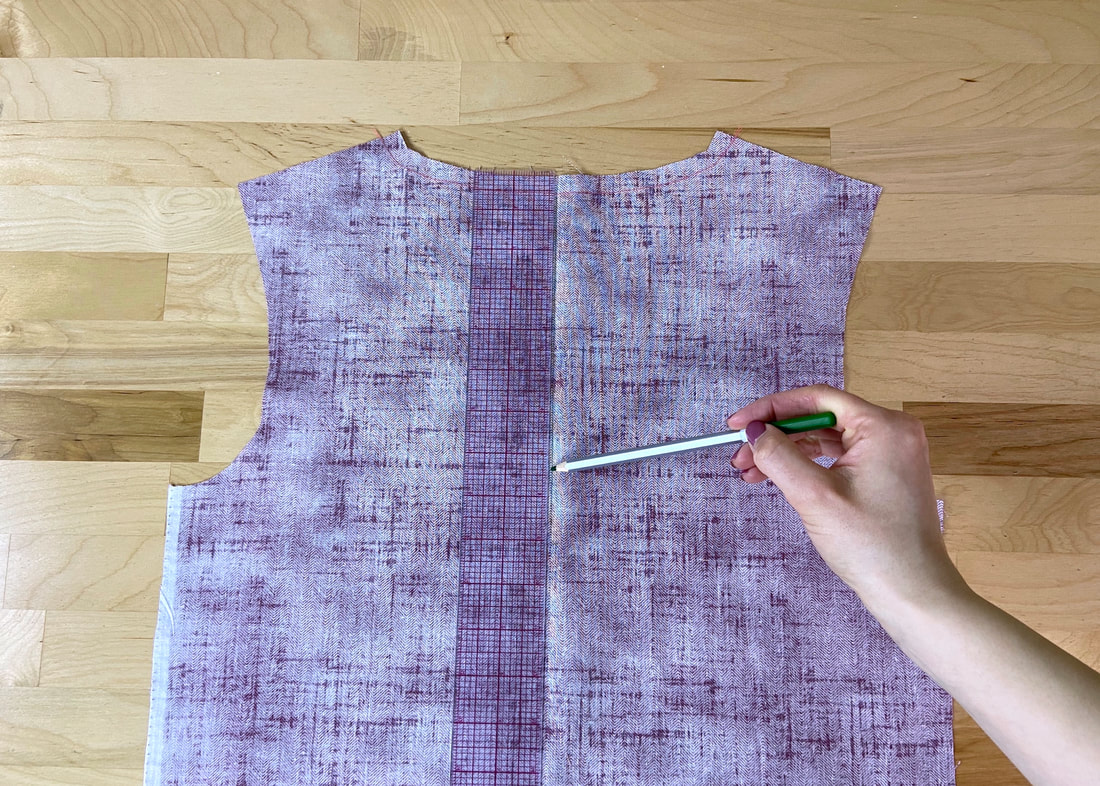

The exposed zipper in this tutorial will be inserted at the neckline into the center back. The neckline edge is not finished until after the zipper is inserted. The same goes for the shoulder seams and side seams. It’s simply much easier to insert the zipper before all these seams are completed.

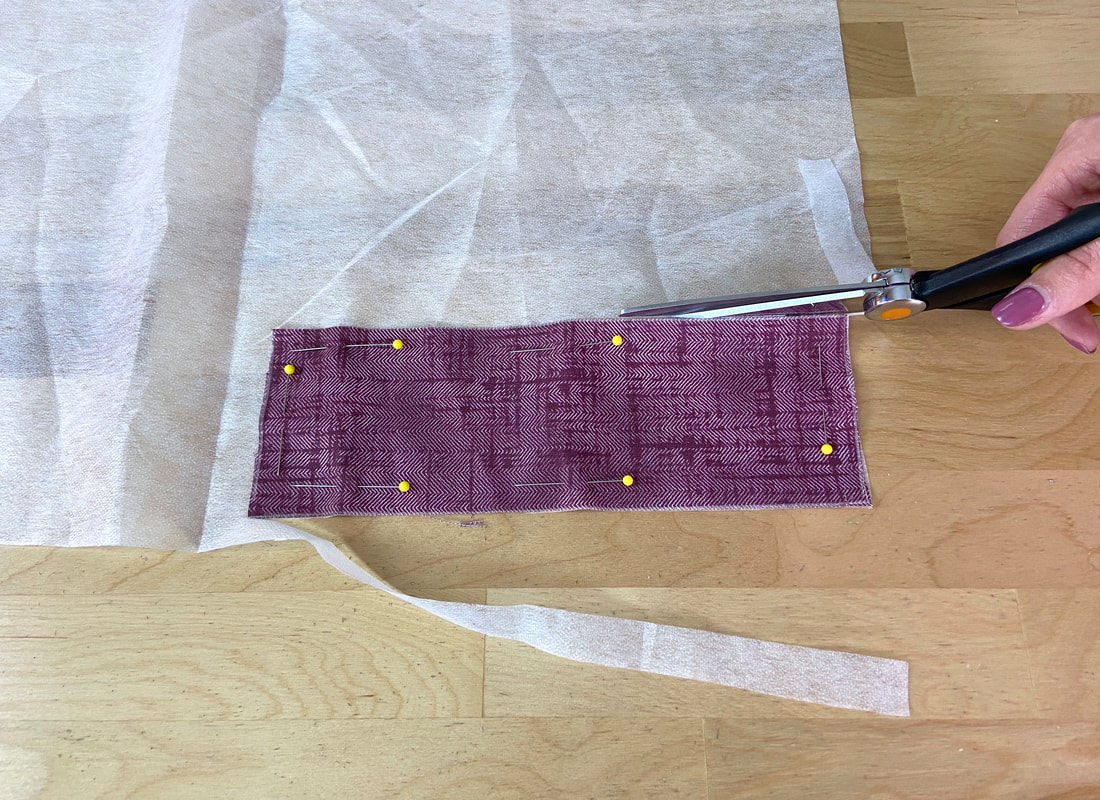

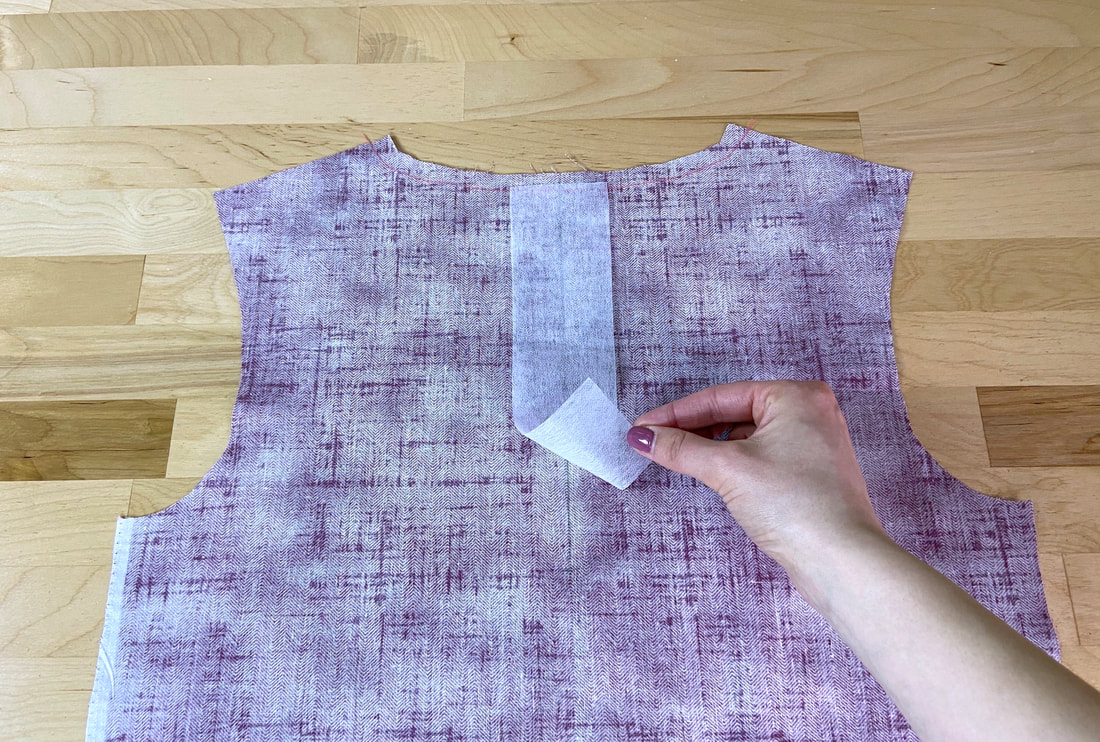

2. Use the facing (stay) as a template to cut a matching piece of fusible interfacing.

3. Trim the fusible interfacing by about ½” along each edge.

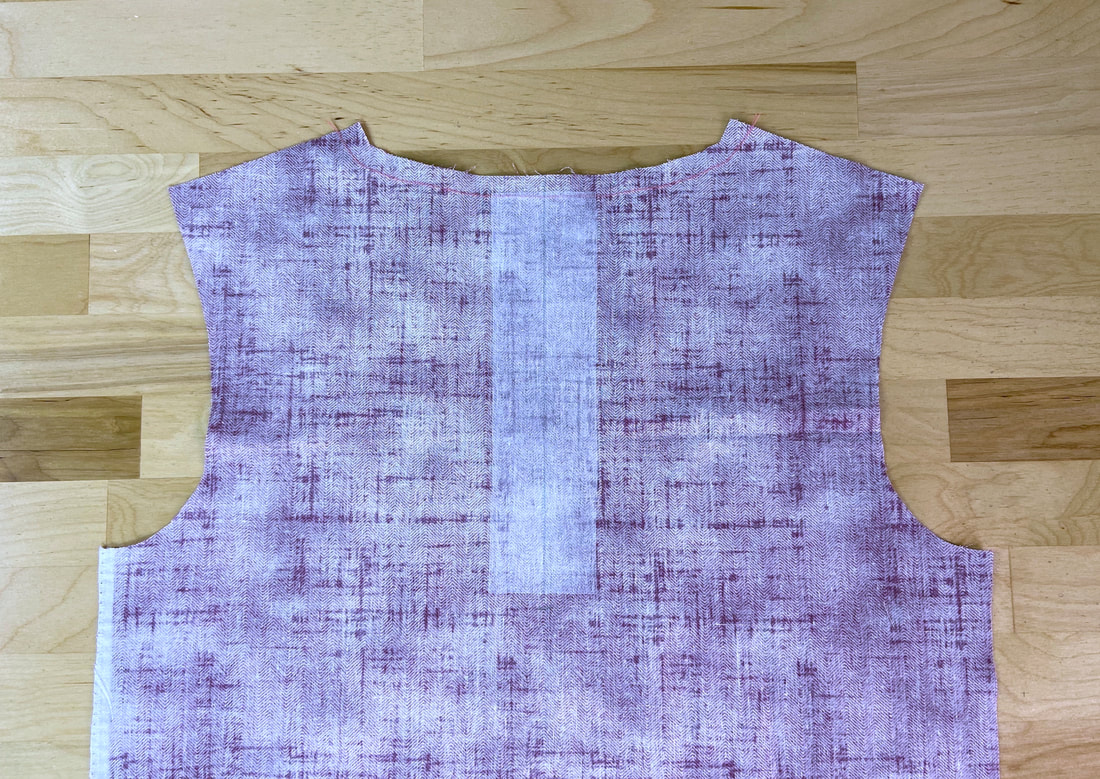

Align the interfacing to the wrong side of the garment fabric, centering it at the location where the zipper will be inserted.

It helps to mark a vertical line with tailor’s chalk to indicate the exact position of the finished zipper- mark this line on the wrong side of the fabric. It should also fall exactly down the middle of the interfacing.

4. Fuse the interfacing at this location on the garment.

5. Using a ruler and fabric pencil (or tailors chalk) and marking on the wrong side of the fabric as shown, draw a vertical straight line down the center of the facing piece. To find the center line, it helps to fold and iron the facing to crease the middle first.

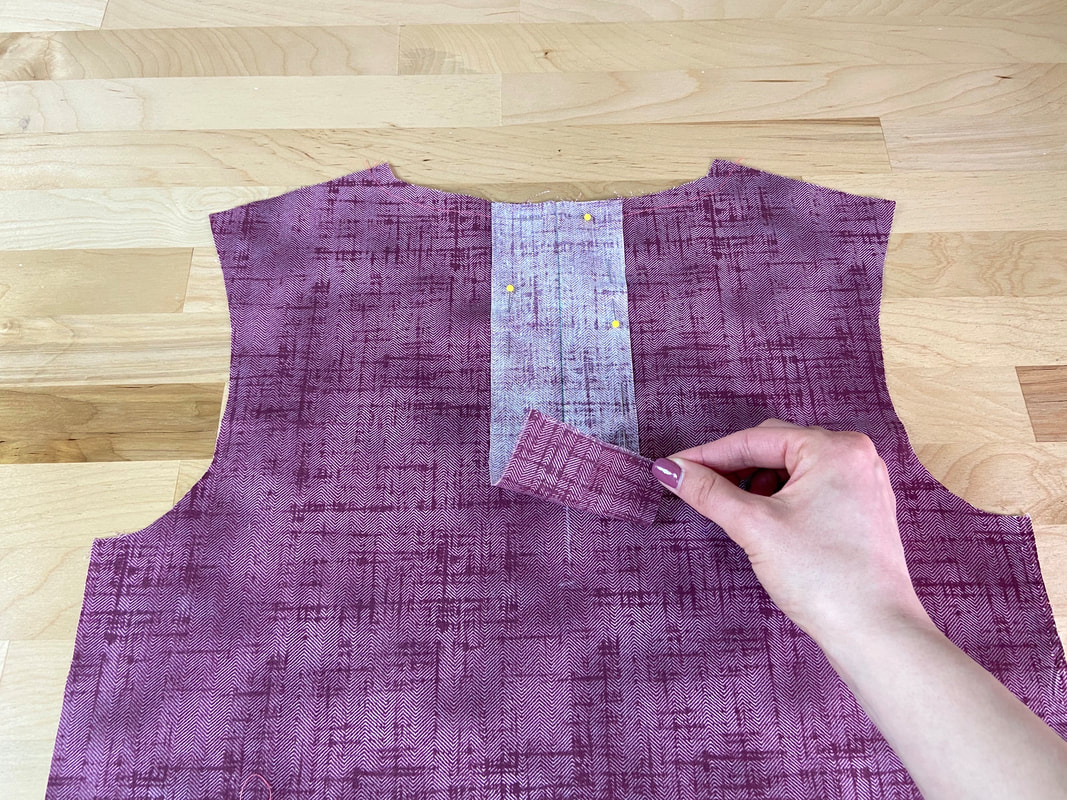

6. Mark the zipper placement line on the right side of the garment. With the garment on its right side, align the facing strip such that the fabric right sides are touching and the center marked lines on both garment and facing are overlapping. Insert a few pins through both fabric layers to hold them in place.

7. Place the zipper next to the vertical marked line, and aligning the very top edge of the zipper tape with the top edge of the unfinished neckline, note the end of the zipper bottom stop on the facing center line as shown. This will mark the bottom opening of the zipper slot.

8. Hand baste the facing to the garment layer at about 1/8"-1/4” away from the center line on all sides. This distance will create a slot that is wide enough to expose just the zipper teeth.

If your design requires that a portion of the zipper tape is also visible (for design purposes), hand baste at about ¼” away from the center line.

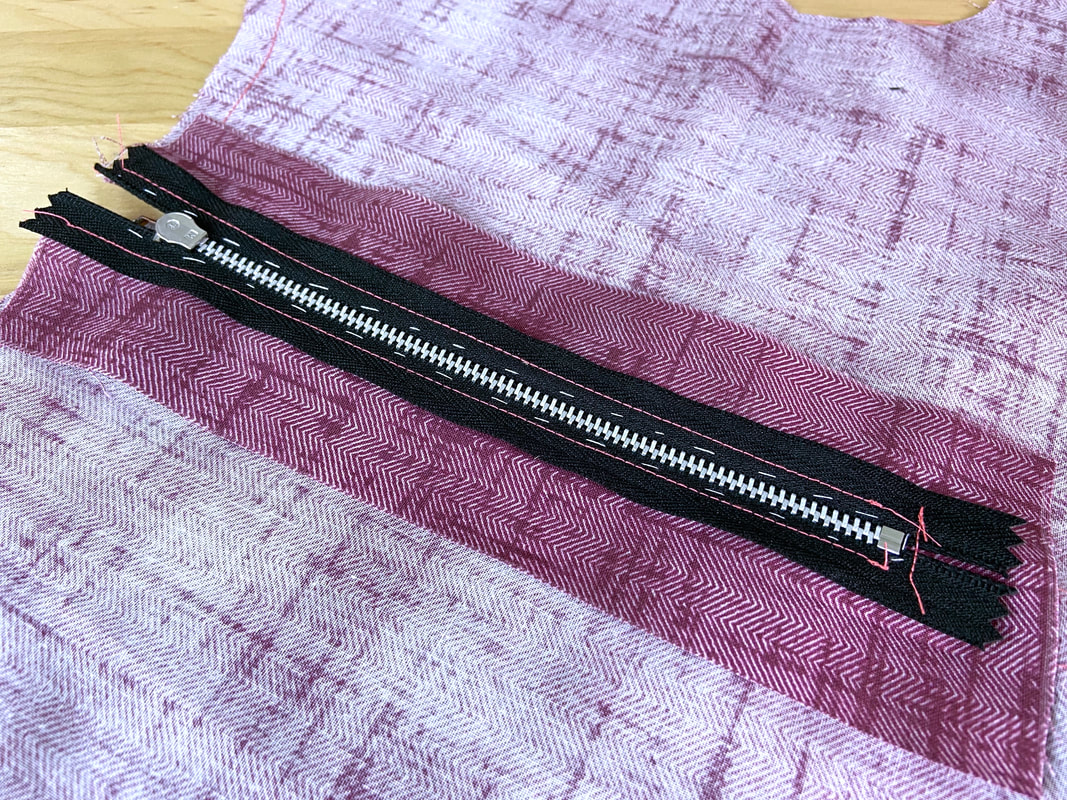

9. Using a shorter stitch length for extra durability, machine stitch next to the hand basting, pivoting the stitch on top of the marked horizontal dash from Step 7 above. The bottom stitch should have perfect right angles. The completed stitching will feature a slim rectangle shape with a vertical center line positioned down the middle.

Remove the temporary hand basting at this point.

10. Next, starting at the top (neckline edge), cut down the center line until you arrive at about ½” from the bottom horizontal stitch.

11. At this location, cut into each corner carefully as shown. Cut as close to the corner as you can but be careful not to clip through the stitching.

12. Flip the facing toward the inside of the garment such that the clean finished rectangular slot is exposed. Press the slot to flatten the finished edges.

13. Position the closed zipper into the slot such that the zipper bottom stop is located right above the slot’s bottom faced edge. Insert a few pins for extra stability.

14. To keep the zipper in this position during the next few steps, it is recommended that you slip-baste through the folded edges and zipper tape on both sides. You’ll see why this is helpful as you move through the steps to follow.

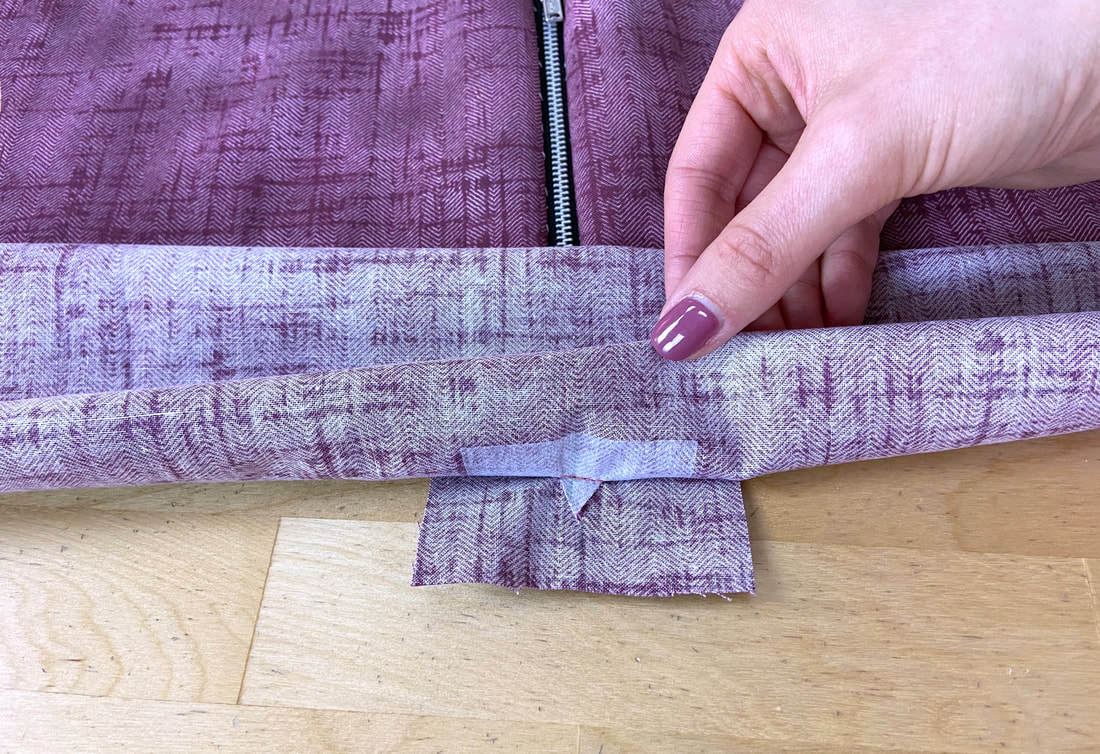

15. Keeping the zipper flat, flip the bottom garment layer up to expose the triangle cutout, facing bottom and zipper tape edges underneath.

16. Keeping these three layers perfectly aligned on top of one another, use a zipper presser foot to stitch a few times at the base of the triangle through all layers underneath as shown. Use a short stitch length for extra stability. Once finished, place the bottom garment layer back down.

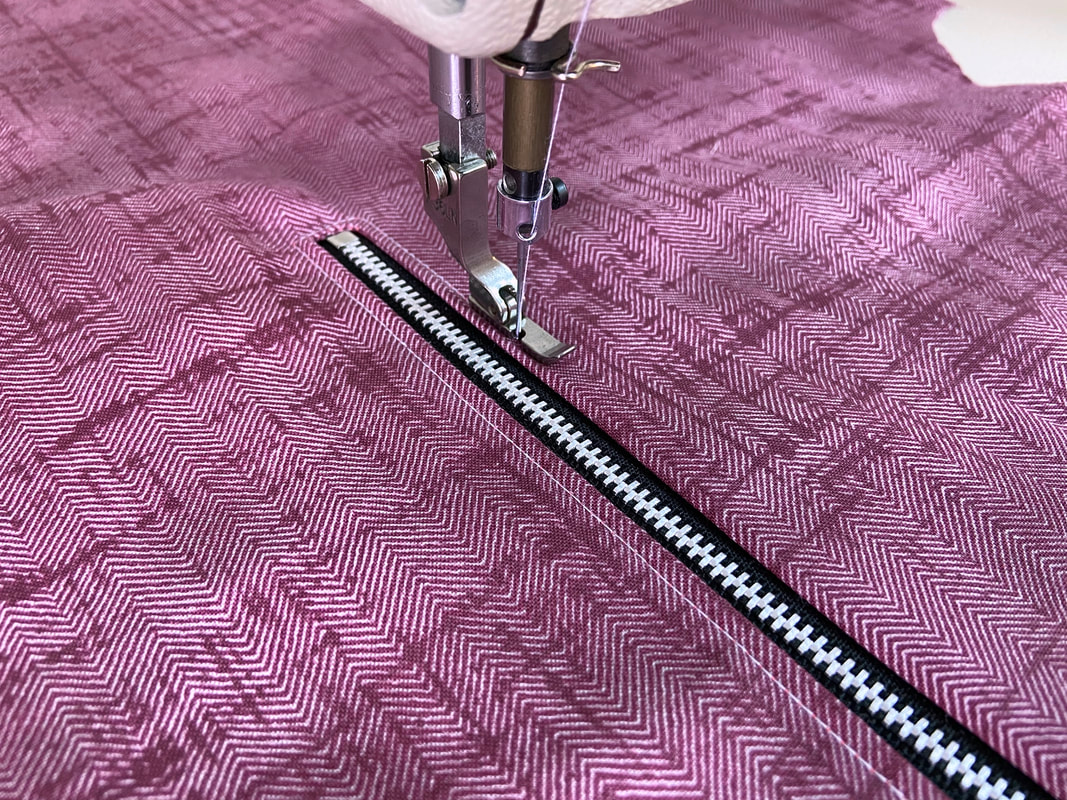

17. Next, flip one side of the garment over to expose the vertical edge of the facing and zipper tape.

Using a zipper presser foot again, machine stitch next to the zipper teeth through the facing and zipper tape layers underneath as shown. Start at the bottom and move up, following the stitch line already present on the facing layer.

18. Repeat the stitching process on the other side of the zipper.

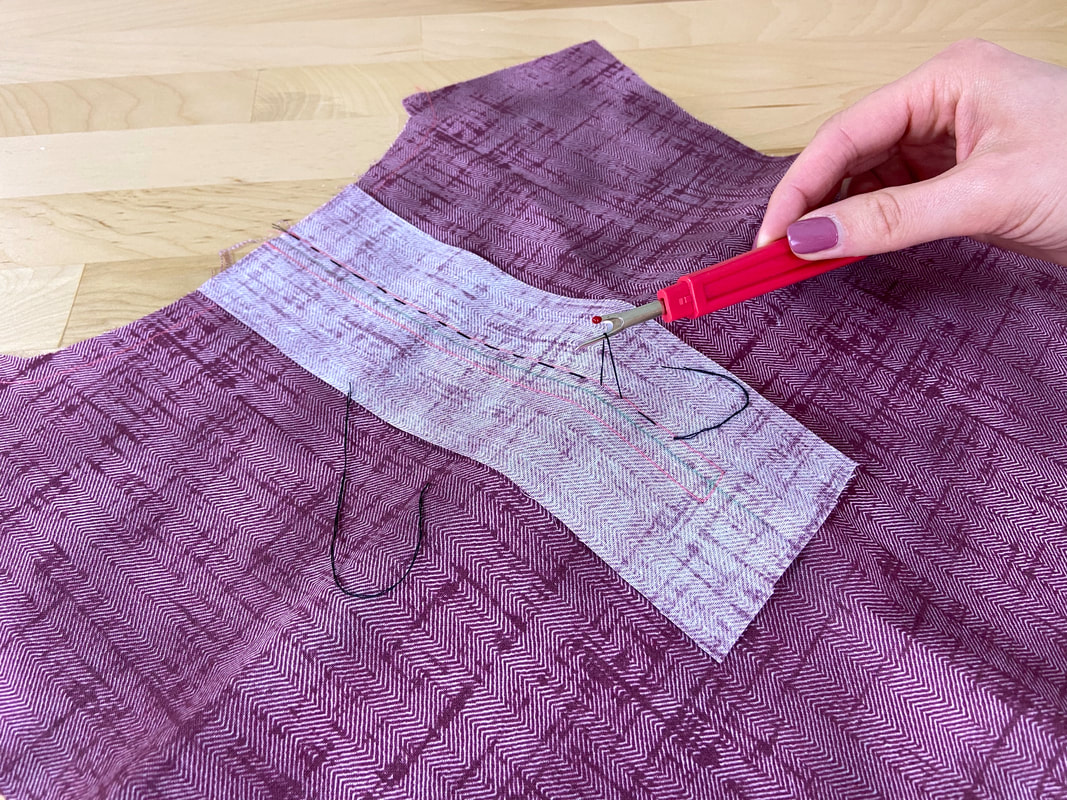

19. Flip the exposed zipper on its right side and remove the slip basting using a seam ripper.

20. Clean finish the facing edges if you haven’t done so already. In this tutorial, a serging stitch is used along all raw edges.

At this point, you may choose to topstitch or add decorative elements around the exposed zipper teeth.

If the zipper features a metal chain (as it does in this tutorial), you can safely iron the completed zipper application to achieve a smooth, professional finish. Exercise care when ironing plastic coils- some of them can melt if directly touched by the iron hot plate.