Notching seam allowance means cutting triangle-shaped wedges or simply slashing close to the seamline to release tension and allow curved seams to lay flat. Notches may cause a bit of confusion for sewing beginners since there are two different types of notches used in dressmaking.

One type discussed in this tutorial, What Are Notches And How To Use Them In The Sewing Process ,provides seam allowance markers used to match corresponding seam edges to one another.

On the other hand, the tension-release notching discussed in this tutorial is a collection of snips or triangle-shaped cuts that are applied to the seam allowance of curved seams to release tension. They are also used to prevent fit and strain issues within the garment’s other seams and finished edges.

In terms of tension release notches, there are two separate styles you should be familiar with: triangle-cut (wedge) notches and plain slashes. These two notching types are interchanged based on whether the curve is facing inward or outward.

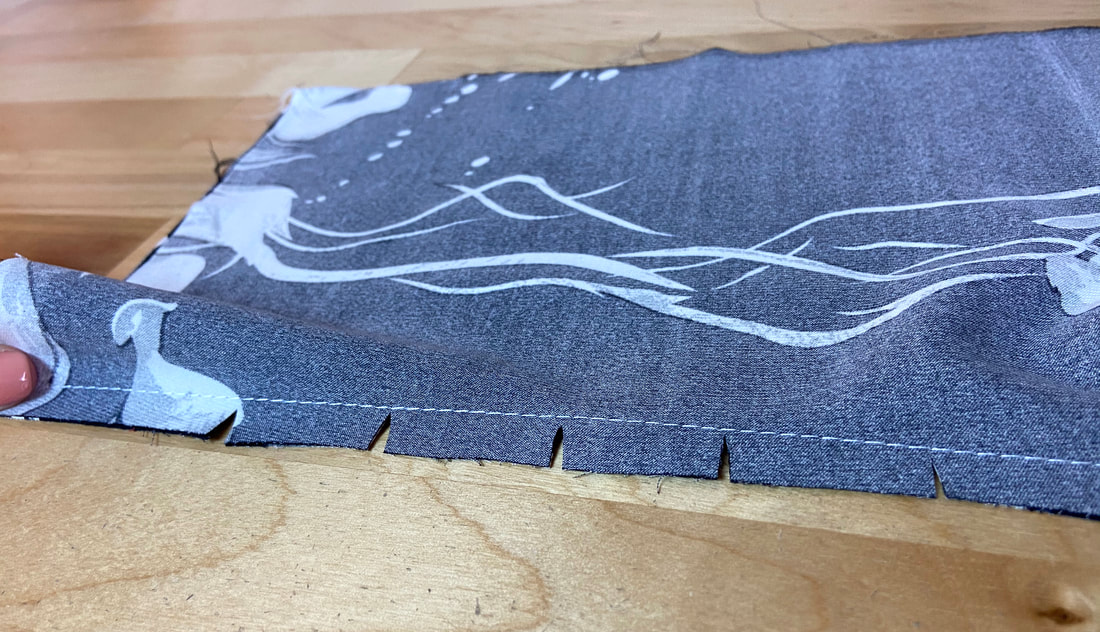

Using Plain Slash Notches

This method is a simple slashing of the seam allowance starting from the edge and ending close to the stitch line. It is mostly used on inward curves.

These simple clips allow the seam allowance to spread apart thus allowing the notched edge to mold and adjust to its corresponding seam edge.

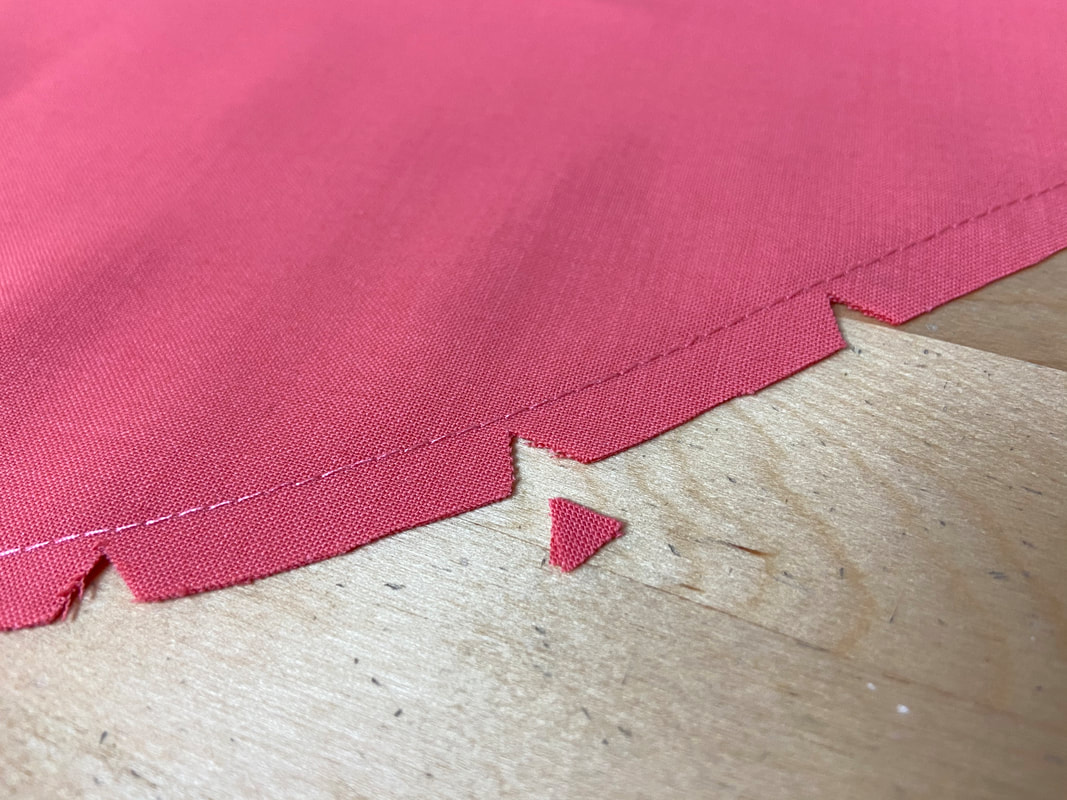

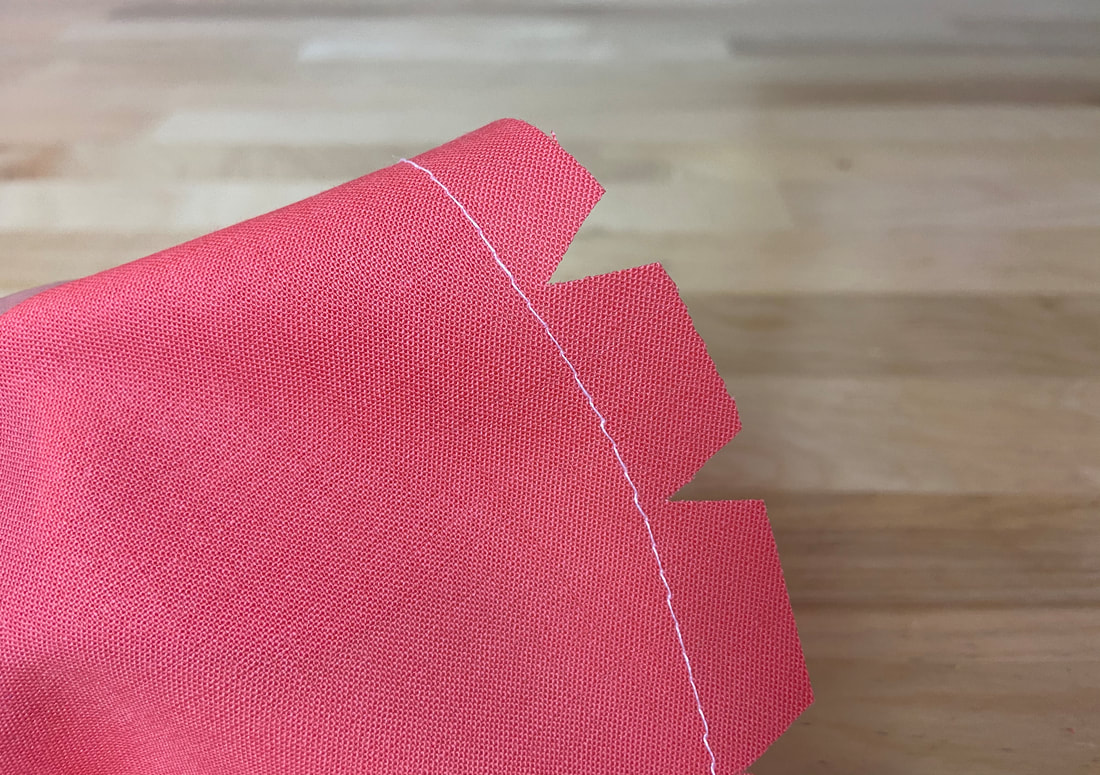

Using Triangular Wedge Notches

As opposed to the simple slashes described above, these notches are cut in a triangular or wedge shape. They are mainly used on the seam allowance of outward-facing curves to provide both flexibility and a way to remove excess that prevents curved seams/edges from lying flat.

The wedge cutouts draw in the seam allowance to remove unnecessary bulk. If outward curves are not notched with triangular cutouts, the seam allowance excess will gather together and create extra bulk and puckering in the finished seam.

There are two main instances when notching the seam allowance is needed in the construction process:

- To aid in the process of matching unlike curves/shapes when seam edges are aligned.

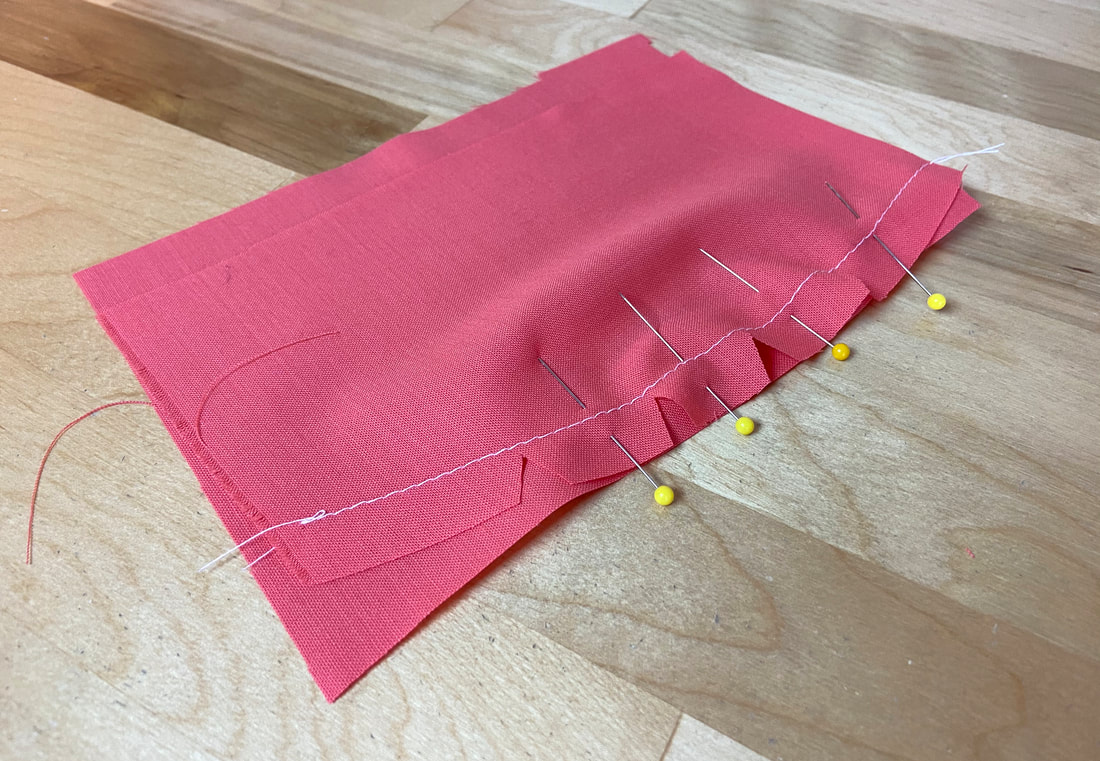

Notching the seam allowance is done on individual edges prior to the seam being aligned and stitched. In this case, staystitching is used to first reinforce the fabric edge prior to notching it.

Staystitching is a stabilizing straight stitch which maintains the strength and structure of the notched seam edge.

You can learn more about staystitching in this tutorial: Staystitching

- To release tension in curved seams and enclosed edges after the seam has been stitched.

In this instance, the notches are applied to seams formed from identical curved edges that are easy to align, pin and machine stitch. Notching is applied to both seam allowance layers to release strain and tension in the finished seam or enclosed edge.

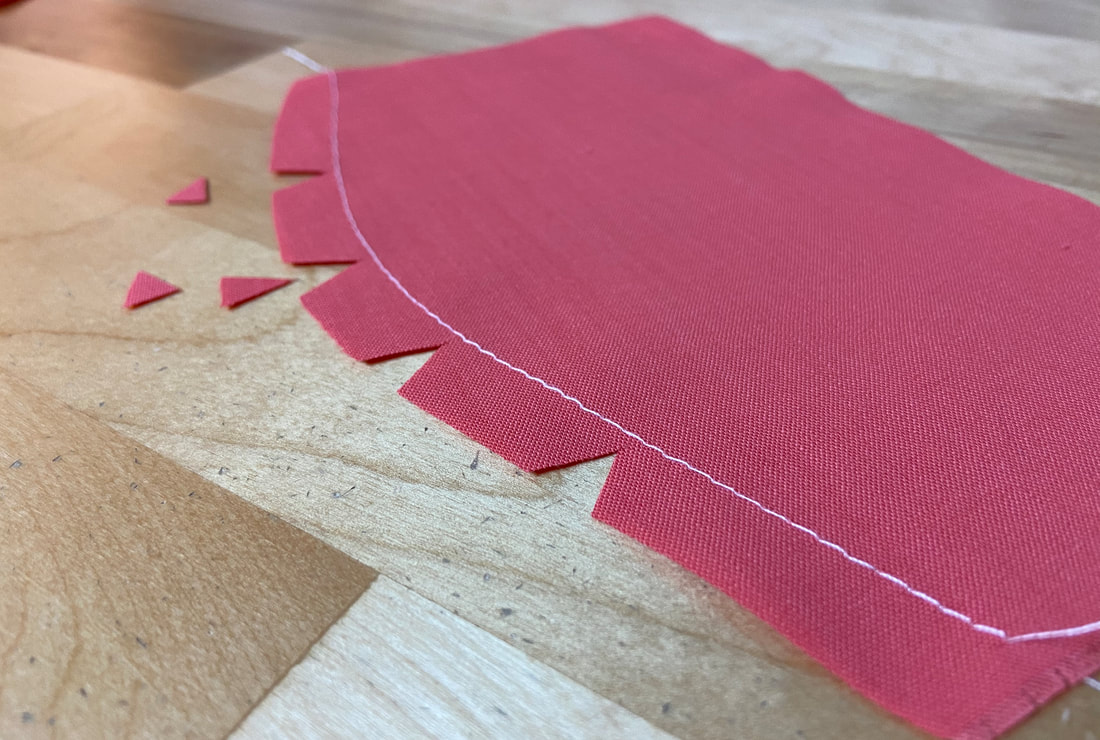

The best example of notching seam allowance for tension release (whether using slash or triangle notches) is when sewing faced necklines and armholes. After the facing has been stitched to the garment neckline edge, the seam allowance is trimmed (if necessary), graded, and notched.

Triangle notches are applied to the seam allowance along the most curved areas to allow the finished neckline edge to lay flat in a continuous smooth curve.

The wedge and/or slash notches should be clipped as densely as needed to release tension but not so much that it weakens the seam. Particularly in the case of loosely woven fabrics, keep the notching to a minimum.