You may be surprised by how often you’ll find yourself having to sew a corner seam in the dressmaking process.

Luckily, sewing corners is fairly simple and can be quite fun, especially when achieving a good end result.

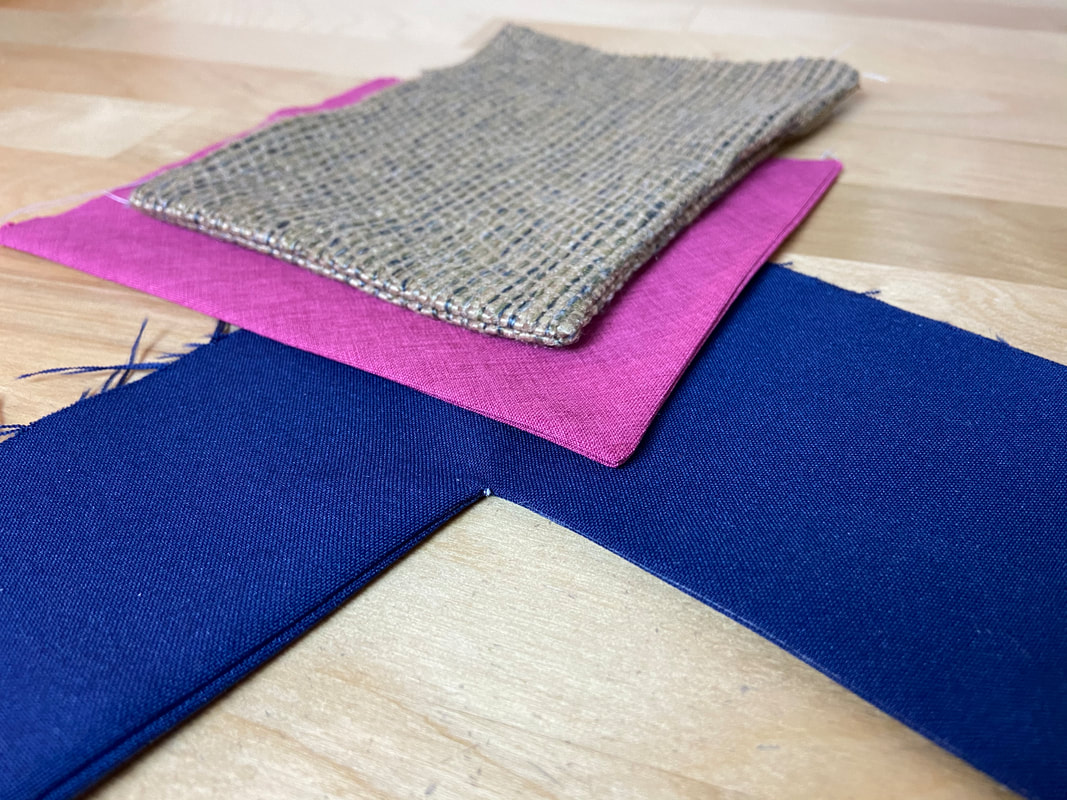

These unique seams are usually fully enclosed as clean-finished angular edges which you can often find on collars, cuffs, faced garment openings, lapels, and skirt/dress vents.

There are a few different corner stitching techniques used to both facilitate the construction process as well as achieve a bulk-less, sharp and flat seam finish.

Here are three different types of corner seams and best practices for sewing them:

Sewing Outer Corner Seams

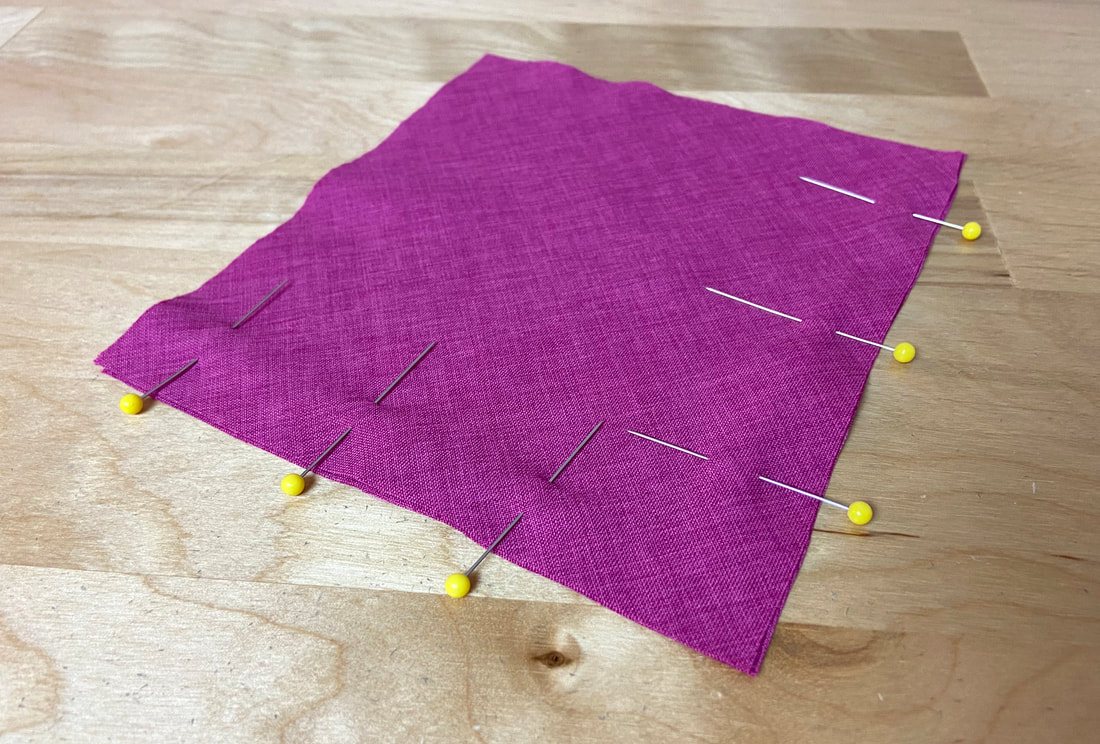

1. Align the two fabric layers on top of each other with face sides touching and the corners aligning. Insert pins or hand baste to keep the fabric layers in place.

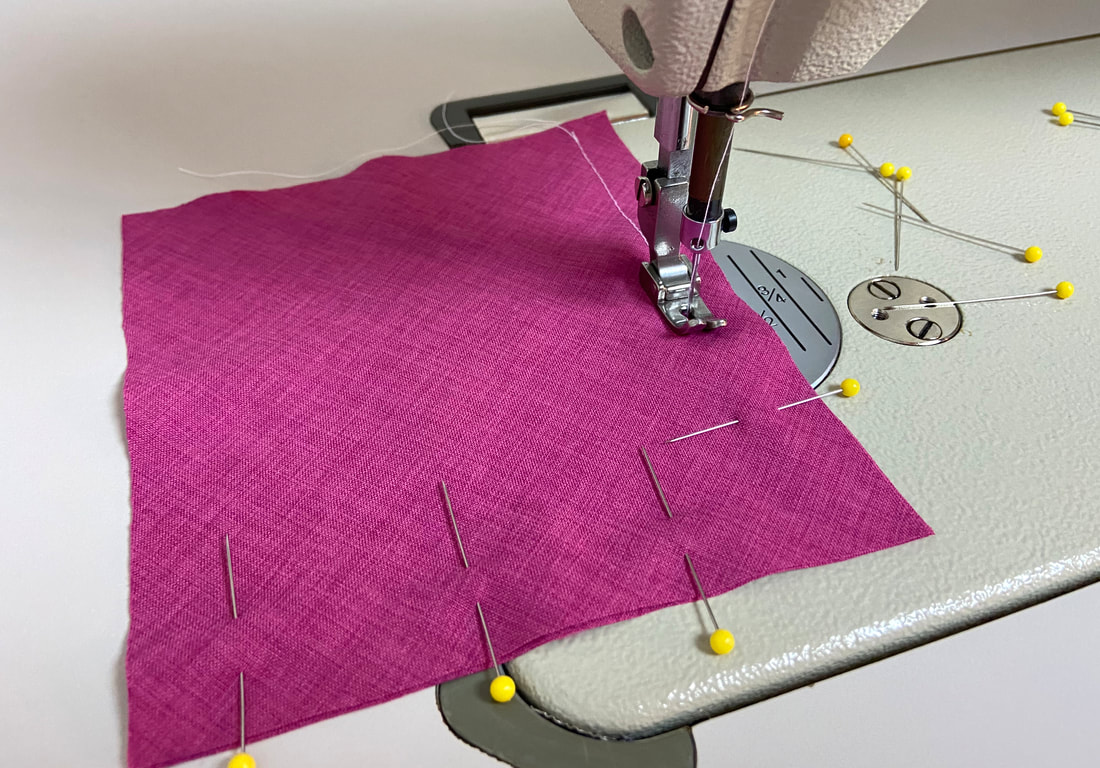

2. Starting along the vertical edge, begin stitching at the designated seam allowance (1/2” in this example) moving down towards the corner.

Along with your seam allowance guides, your sewing machine may also provide horizontal crosslines intersecting the vertical allowance guides. These horizontal lines are positioned at the same distance down from the sewing machine needle. They are used as a guide for when to turn the corner based on its seam allowance.

If your sewing machine does not provide these crossline guides, add a piece of masking tape from the needle point down to the same distance as the corner seam allowance.

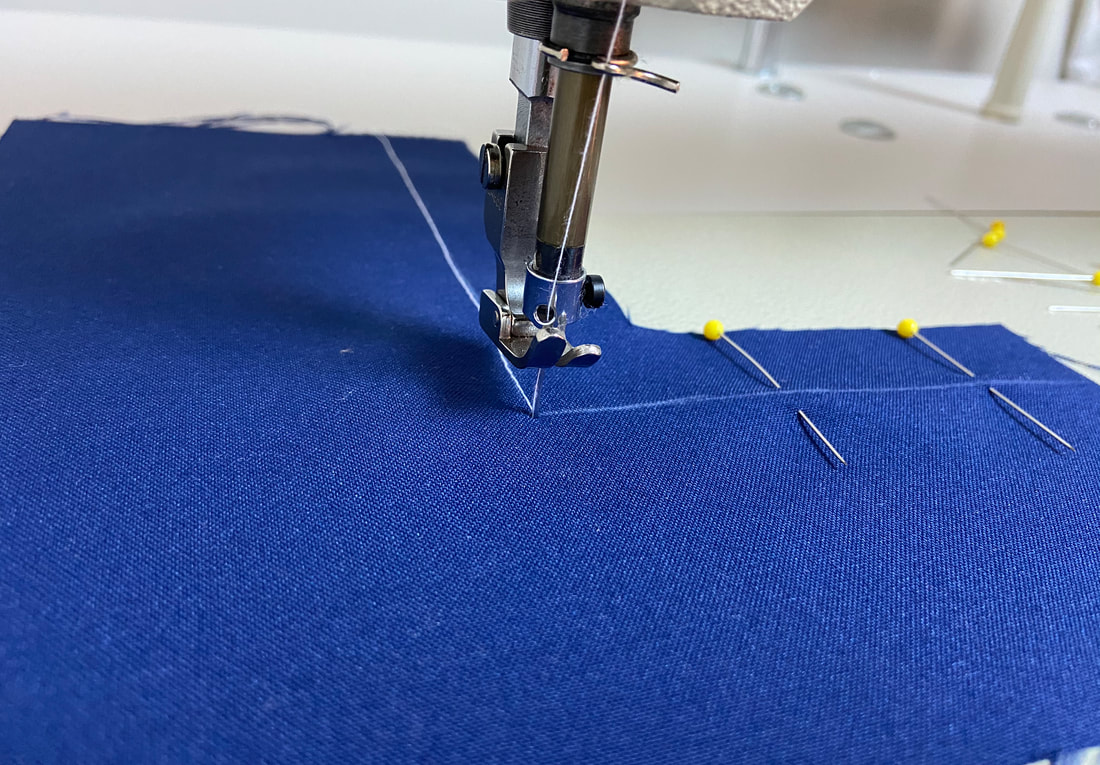

3. When the fabric’s bottom horizontal edge aligns with the designated crossline, lift the presser foot leaving the sewing machine needle in, pivot the fabric such that the horizontal fabric edge is now oriented vertically and aligning with the appropriate seam allowance guide.

4. Drop the presser foot and continue stitching.

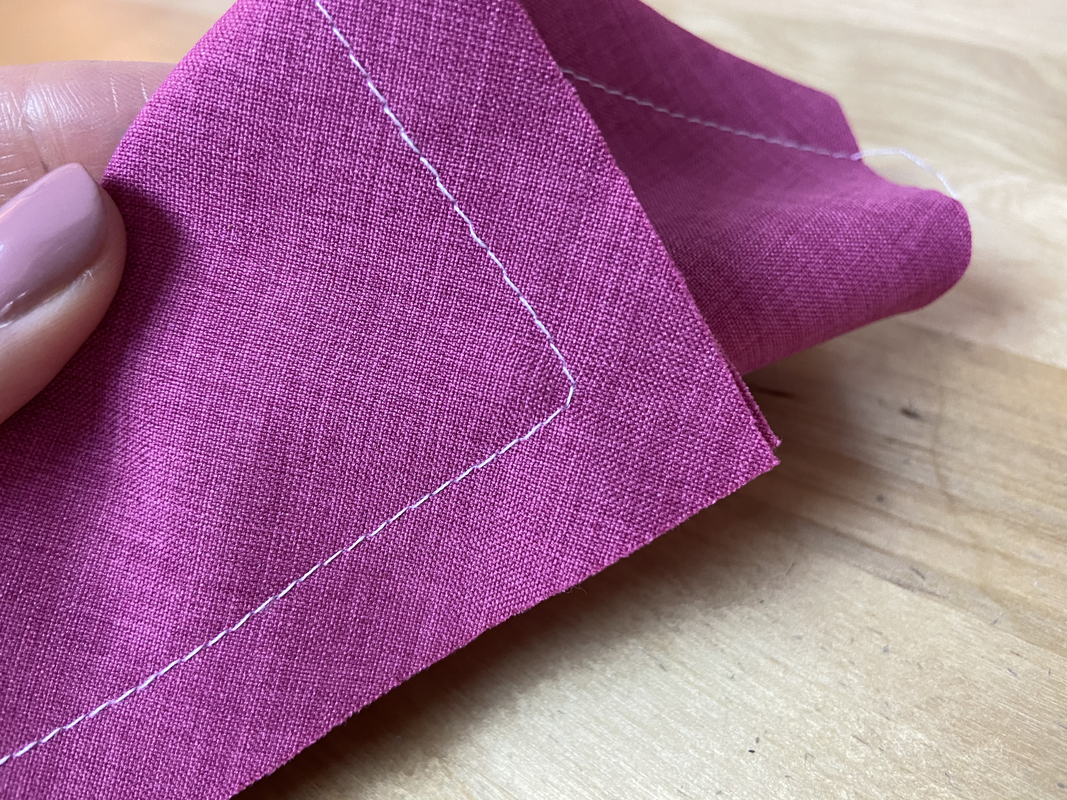

Sewing outward corner seams is encountered mostly on fully-enclosed corners. These corners are widely used in dressmaking requiring a defined edge that is sharp and lays flat. To achieve this professional finish, a technique called blunting is used when stitching the corner area.

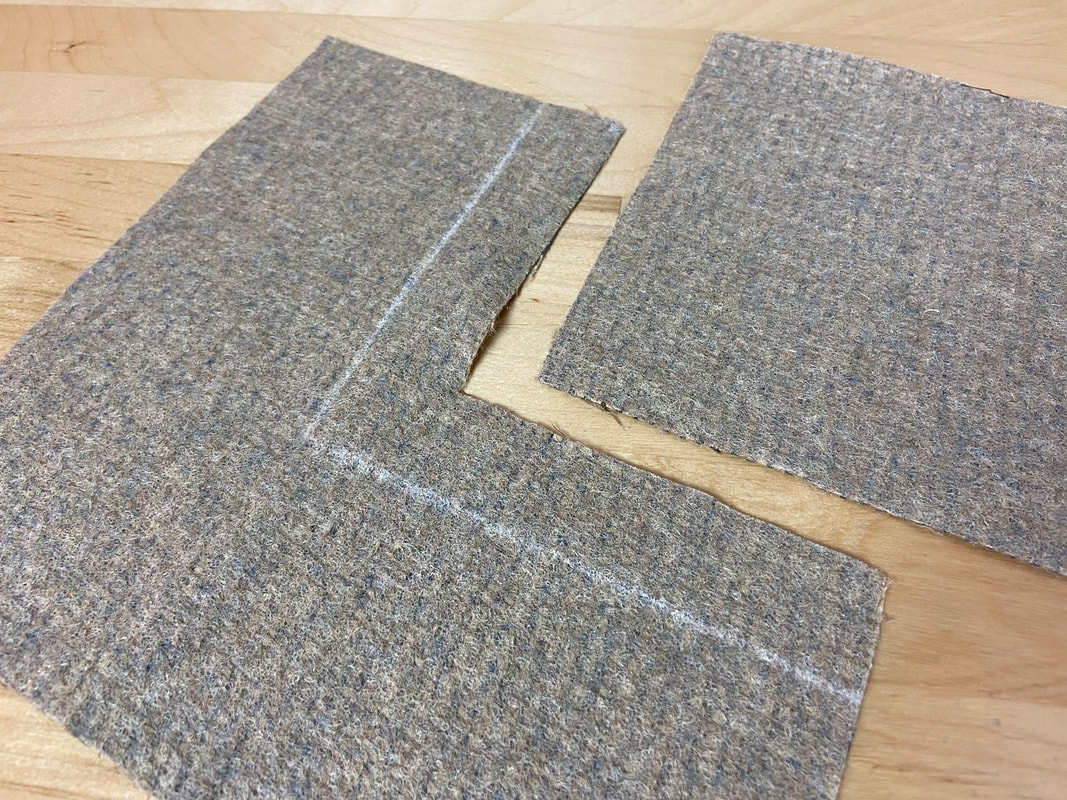

Blunting a corner means that instead of a sharp transition (pivot) from the vertical to the horizontal stitch, 1-3 stitches are added diagonally at the corner while shifting direction. The amount of stitches needed for blunting is based on fabric thickness.

Lightweight fabrics only need a single diagonal stitch, medium weight fabrics will often need two diagonal stitches, while heavy/bulky fabrics may require three or more blunting stitches. This subtle diagonal stitching allows room for the enclosed seam allowance to sit in a position that forms a flatter, sharper corner.

Additional to blunting, the seam allowance requires to be trimmed diagonally in order eliminate overlapping bulk.

Sewing Inner Corner Seams

Just like sewing outer corners, inner corners require the same type of pivoting action in the stitching process. The only difference is the direction of the pivot. Blunting is not needed on inward corners.

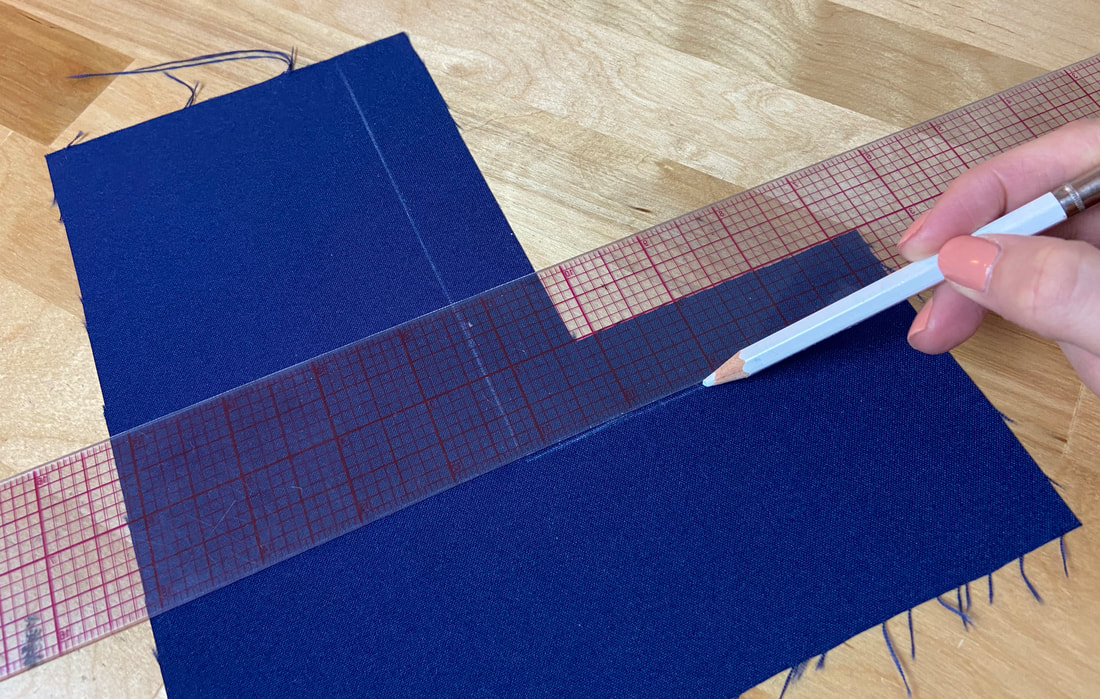

1. To facilitate the stitching process, start by marking the corner seamlines directly on the fabric pieces. These marked seamlines will provide an important guide when pivoting the corner stitch. To mark the lines, you can use tailor chalk and a ruler or gage pointer.

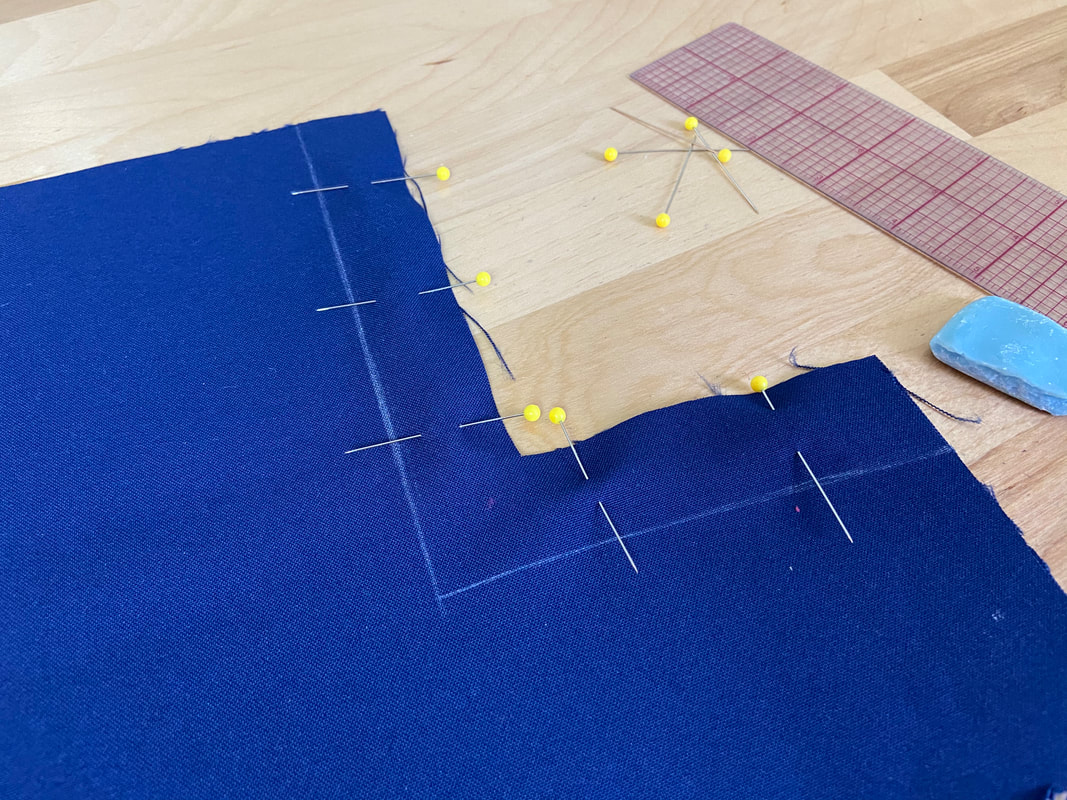

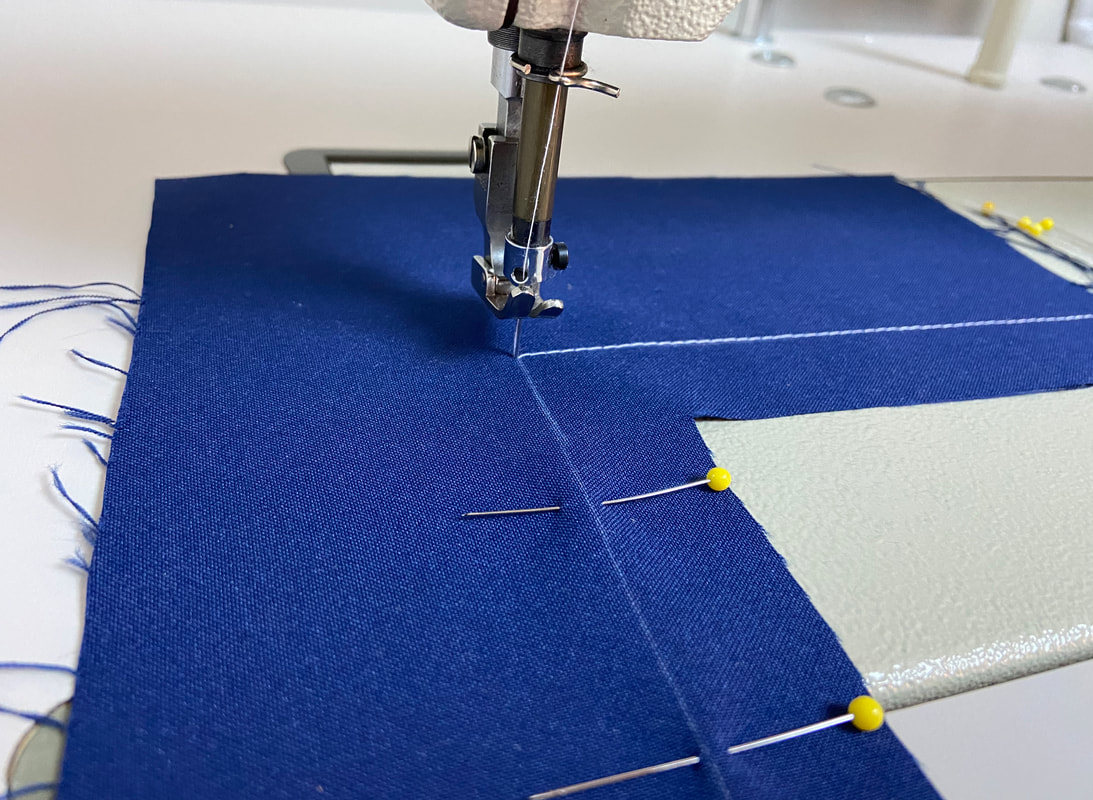

2. Align the matching inner corner edges with fabric face sides touching, and insert pins perpendicular to the edge to keep the fabric layers together.

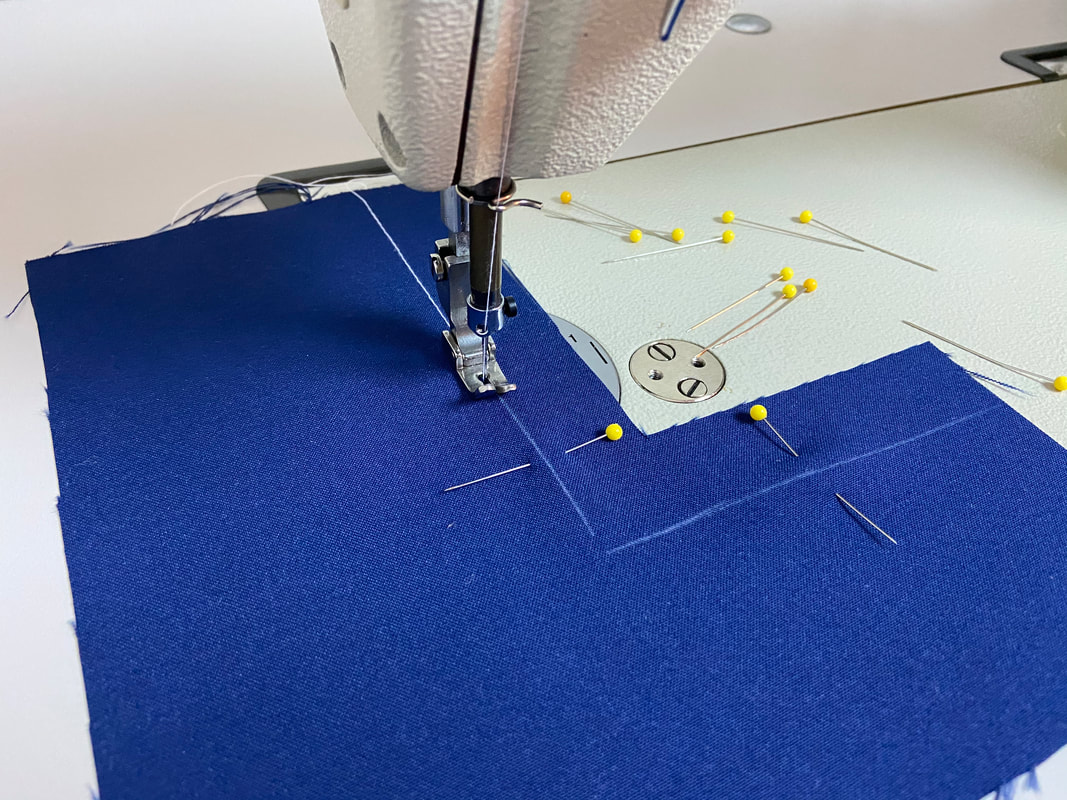

3. Begin stitching the vertical seamline following the marked chalk line as a guide.

4. When arriving at the corner, insert the machine needle through the corner point, lift the presser foot and pivot the fabric layers in the direction of the horizontal seamline.

Drop the presser foot and continue stitching. The end result should be a perfect corner stitch with a well-defined point.

5. To reinforce the corner area, change your machine setting to a shorter stitch, and stitch over the corner, extending about 1” on each side as shown.

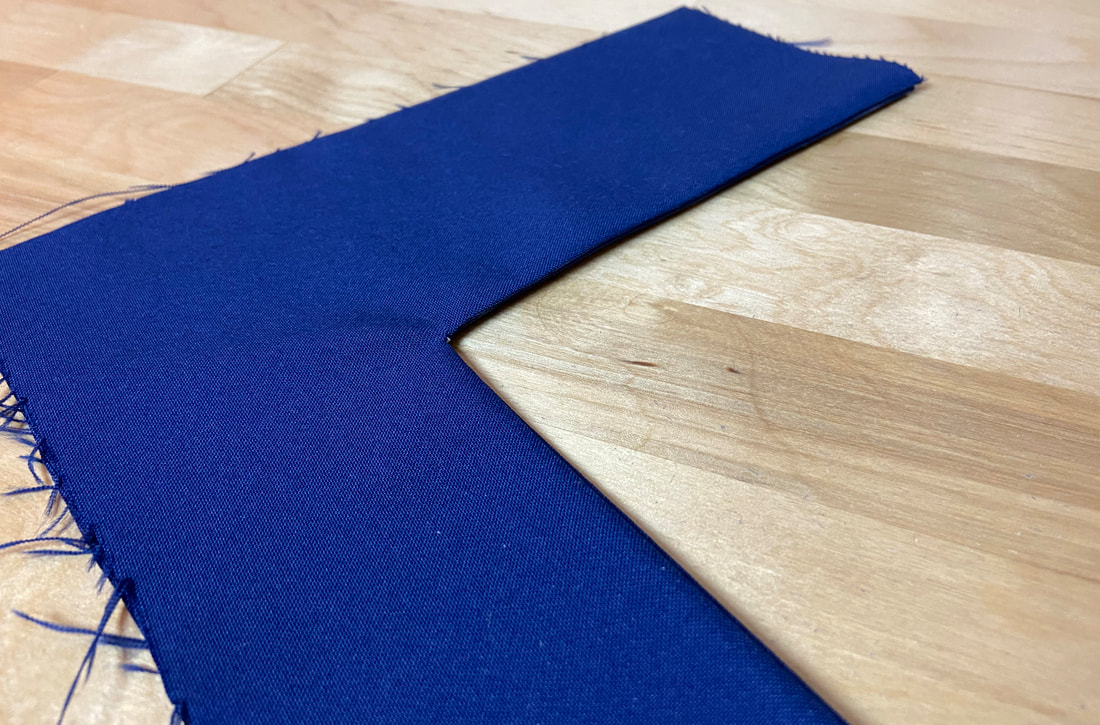

At this point, if you attempt to turn the corner seam on its face side, you’ll find that this is nearly impossible due to the seam allowance tension created at the corner. For that reason, it is imperative that the seam allowance is notched diagonally first.

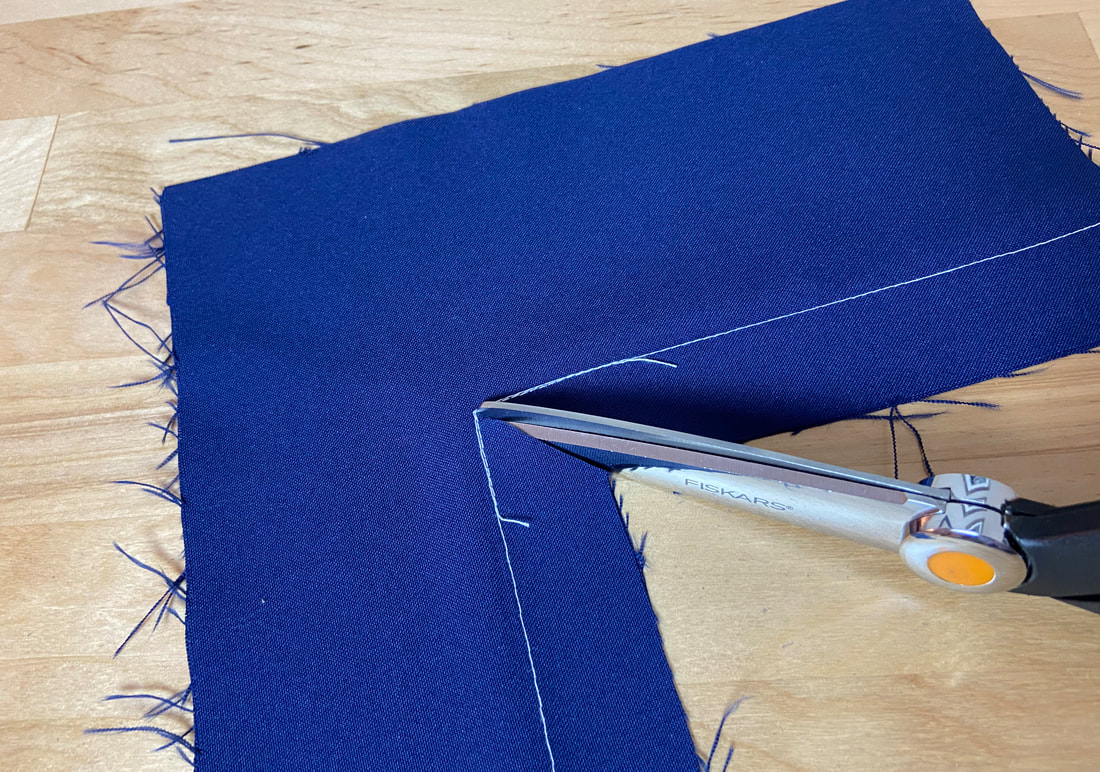

6. Clip the seam allowance from the edge down to the corner point, being very careful not to clip through the actual stitching.

This will release tension in the inner corner seam and allow you to iron it flat as required in your final application.

Sewing An Inner Corner To An Outer Corner Edge

At first glance, sewing an inner corner to an outer corner seems like an impossible task.

However, nothing is impossible in the sewing process with a little confidence and the correct notching technique. Similar to sewing opposite curved edges, sewing an inner corner to an outer one requires some clipping before the final seam is aligned, pinned and stitched.

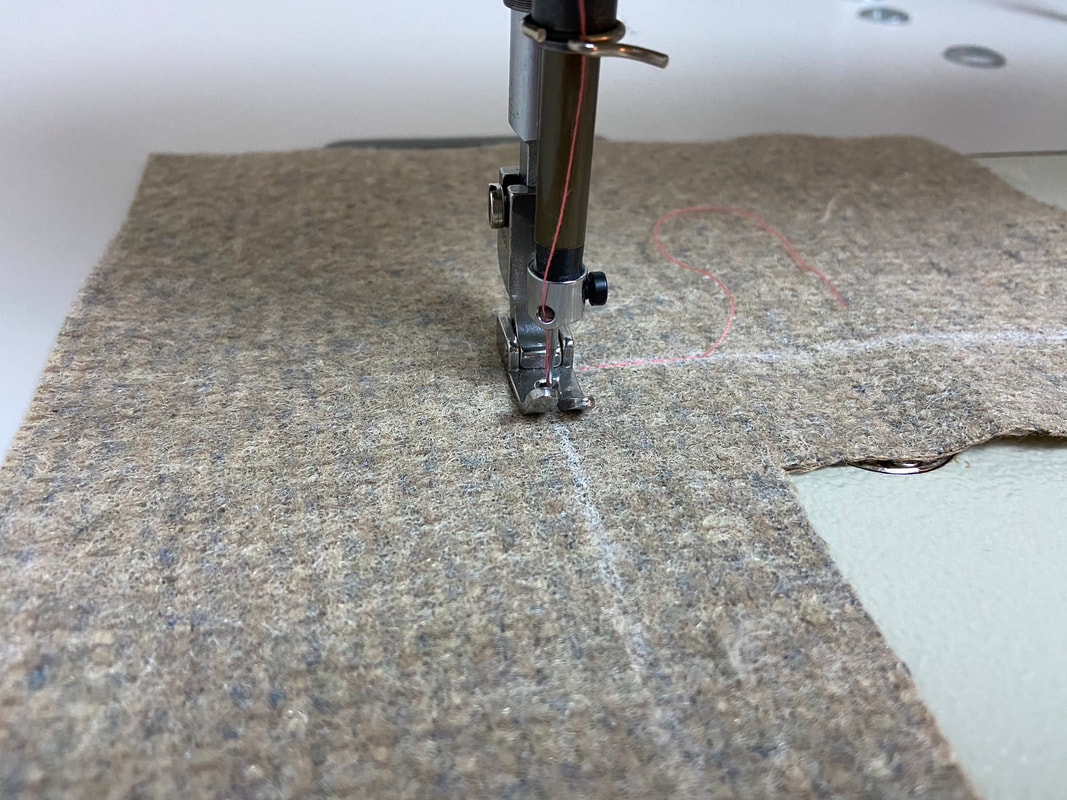

1. Using tailor’s chalk and a ruler, start by marking the seamlines on the wrong side of the inner corner edge.

2. Apply a machine stitch extending about 1” on each side of the corner point as shown. The marked seamlines added in Step 1 above will provide a guideline for applying the stitch perfectly. This stitch serves as a stabilizing staystitch and is only needed along the inner corner edge.

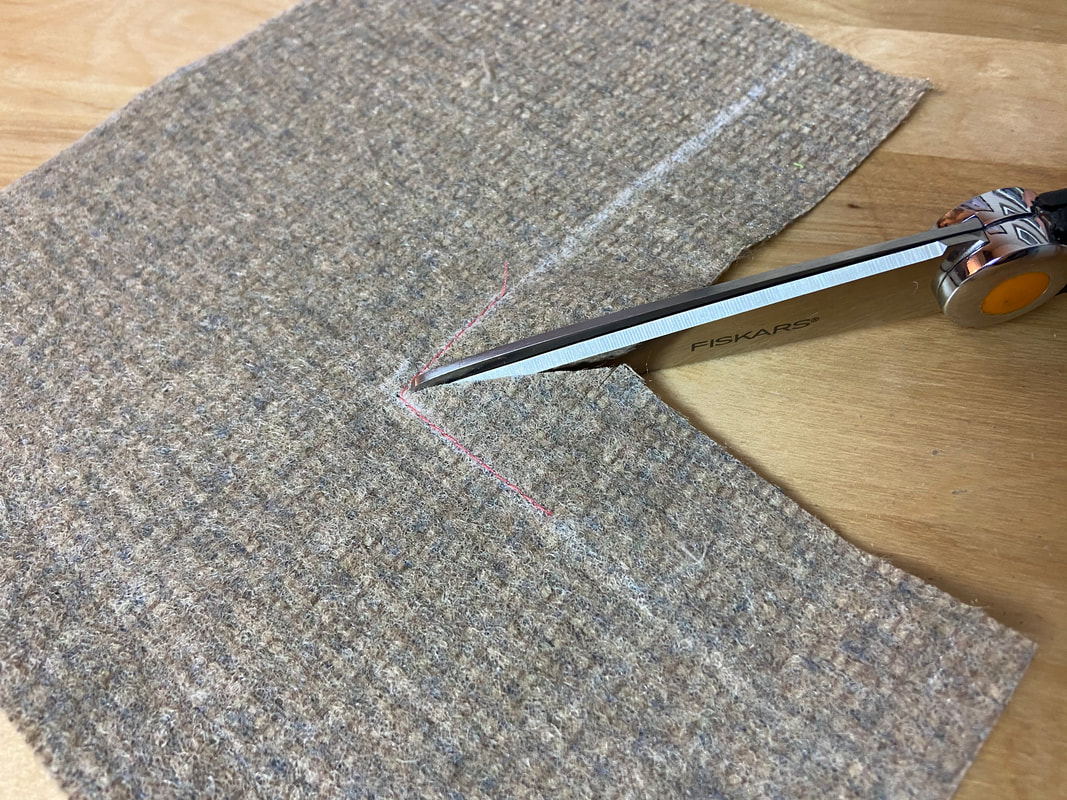

3. Clip the inner corner seam allowance diagonally up to the stitched corner. Clip very close to the corner but be careful not to accidentally cut through the stitching.

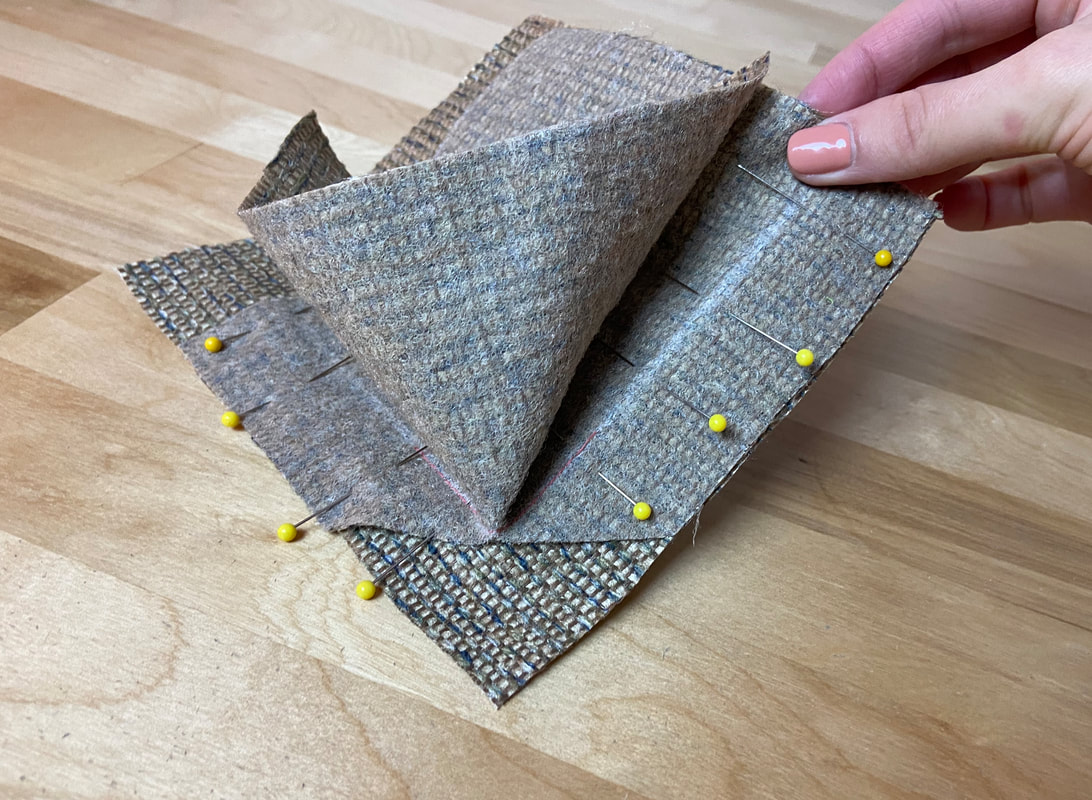

4. Next, place the inner corner edge on top of the outer corner edge with fabric face sides touching. Align and pin the corresponding vertical edges up to the clipped corner point.

5. Spread the clipped edge such that the horizontal fabric edges align, and insert pins to keep the layers in this position.

6. Stitch the vertical edge following the marked seamlines and seam allowance guides on your sewing machine. Stitch until you arrive at the corner point.

Insert the machine needle at this point and leaving the needle inserted, lift the presser foot and shift the fabric layers such that the horizontal edge is now aligned with the machine seam allowance guides.

7. Drop the presser foot and continue stitching the seam.

The final stitch should be perfectly angled and located to the left of the staystitch (pink) applied in Step 2 above.

8. Last but not least, clip any additional excess from the corner seam before turning it on its face side and finally ironing it to complete.

Clipping and notching the corner seam allowance for bulk and tension release will result in a smooth, well-defined corner seam.