A shaped facing is a great way to finish a hem that has an irregular edge or intersecting darts.

The facing is cut to shape around the portion it finishes, encasing all fabric raw edges in the process. As is true with any facing style, whether used for a neckline, armholes, or garment opening, a sewing pattern is used to correctly cut the facing pieces to the exact shape needed.

In the case of a hem facing, if your pattern set does not include the facing, you can use the bottom edge of the garment to draft your own facing portions. A typical facing follows the same exact shape as the edge it finishes. A hem shaped facing is conventionally about 2” in width throughout.

While hem facings are great for irregular hemlines that cannot be folded or clean-finished by other means, they are also great stabilizers. A faced hem is considered a high-quality finish commonly used with structured, tailored garments.

While you can use a facing with most fabrics, keep in mind that it adds an extra layer of fabric which in term, adds structure and bulk to the garment’s hem. If working with very light or sheer fabrics, a facing may jeopardize the desired drape of the finished garment if misused.

Hem facings are great for unlined jackets, tailored skirts, blazers, vests, etc.

When a heavier garment is unlined, a hem facing provides a clean and professional way of enclosing the hem’s raw edge while also providing the needed structure and durability.

Sewing The Faced Hem Finish

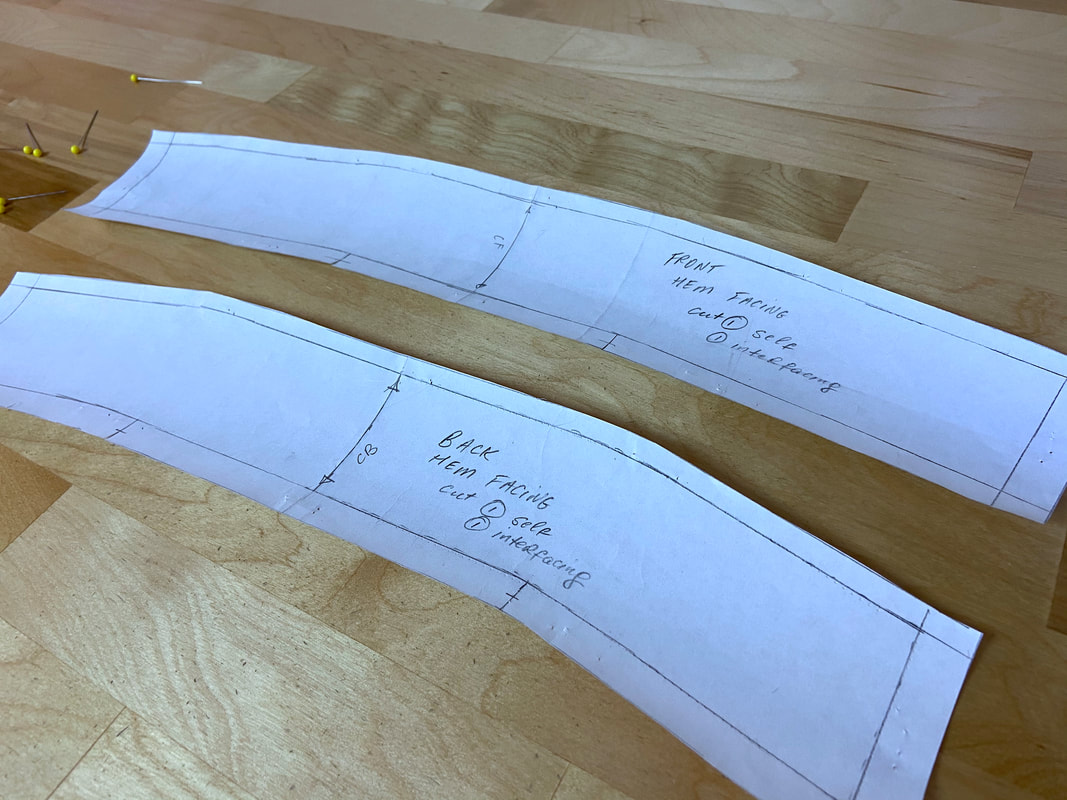

Assuming the hem facing patterns are provided in your pattern set, you should have corresponding pieces for both front and back.

1. Cut out the front and back facing pieces and align the front side seam to its corresponding back side seam edge as shown. Insert a few pins horizontally to hold the facing seam layers in place.

2. Stitch the two facing side seams at the designated seam allowance- ½” in this tutorial.

If working with thick fabric, trim the seam allowance edges halfway down to minimize bulk.

3. Iron the seam allowance edges open as shown.

Before sewing the facing to the garment’s hem, clean-finish the upper edge of the facing.

You can use any of the methods listed in this section: Finishing Facing Edges

4. In this example, the inner edge of the facing was folded at ¼” towards the fabric wrong side. The folded edge was then machine topstitched.

Before aligning the facing to the garment’s hem, make sure all vertical crossing seams (in this case, the side seams) have been sewn, clean-finished and ironed.

In this example, the facing side seams are matching those of the garment. However, some hem facings have less seams than the garment so keep in mind that you won’t always have perfectly matching seams.

The important thing is that the front facing portion is aligned to the corresponding front garment hem. Respectively, the facing’s back portion should fall perfectly in place with the back portion of the hem.

The garment hem allowance should be the same as that of the unfinished facing edge. Luckily, your patterns are designed to account for this matching allowance.

To attach the facing:

5. With the garment on its right side and the facing on its wrong side, match the unfinished edge of the facing to the garment hem such that the facing and garment vertical side seams are aligned.

The front and back portions of the facing and garment should align perfectly. Fabric face sides should be touching.

When correctly aligned, the facing should take on the shape of the garment’s hem.

6. Insert pins perpendicularly through the entire length of the hem to keep the two layers aligned.

6. Machine stitch the facing to the garment hem at the designated seam allowance (consult your patterns). In this case, the seam allowance is ½”.

If you are using only pins (no hand basting) to keep the layers in place for machine stitching, remove every pin as you approach in the stitching process. Do not sew through the pins.

7. Once stitched, extend the facing and all seam allowances away from the garment and iron the finished seam as shown.

8. Understitch the facing layer. To apply an understitch, apply a machine stitch next to the seamline through the facing layer and all seam allowances underneath. This straight stitch will keep the finished edge flat and prevent the facing from rolling to the outside of the garment.

9. Bring the facing to the inside of the garment and iron the finished faced hemline.

10. Last but not least, secure the inner edge of the facing to the garment by hand using your choice of blind stitching technique. A catchstitch or a slipstitch will work best in this case.

First, insert a few pins through the facing and garment layer on the inside of the hem. The pins will keep the facing flat and perfectly aligned.

Insert a stitch through the facing fold then catch a few threads from the wrong side of the garment surface as shown. This process is called slipstitching.

Continue hand stitching until the entire hem is complete. No stitches should be visible on the face of the garment.

For a more casual finish, you may choose to topstitch the facing layer closed.

To topstitch the facing: From the wrong side of the hem, machine stitch through the facing and garment layer underneath using the folded facing edge as a guide. For a clean, professional finish, stitch close to the fold (about 1/8”).