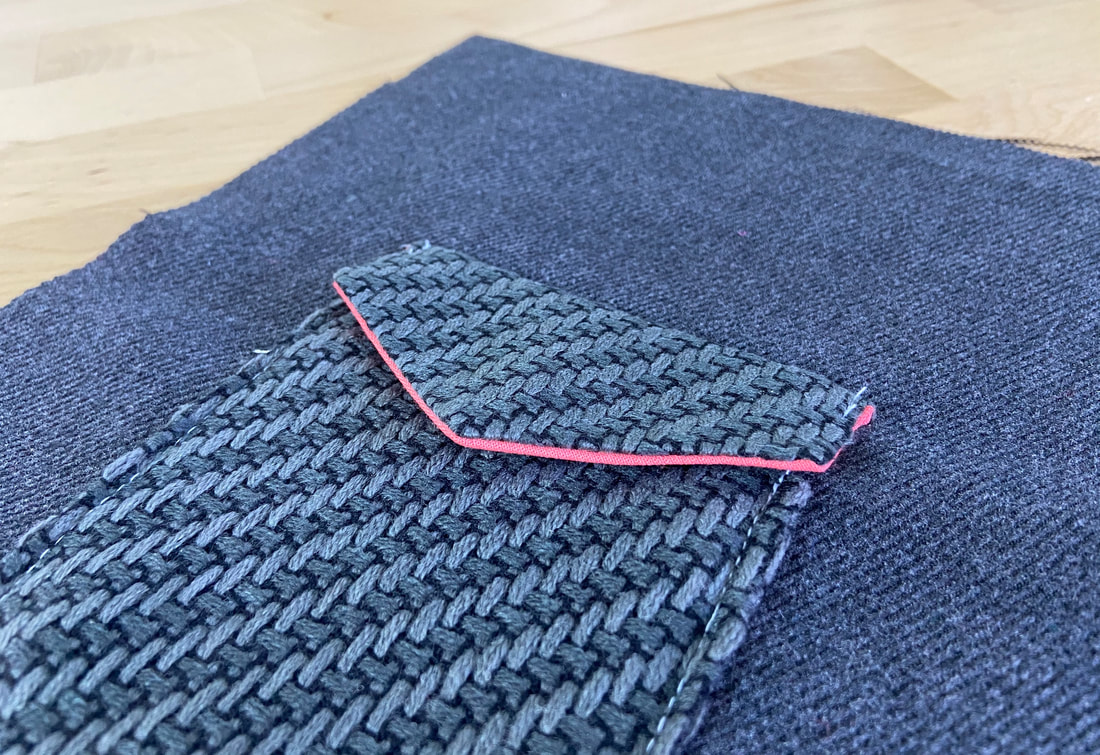

A great way to elevate the design and functionality of a patch pocket is to add a flap to it. Not only does it serve in securing the pocket opening, it also adds a classic decorative element to its overall look.

A flap patch pocket is most commonly used with heavier outerwear items like jackets, blazers and coats. Patch pockets with flaps look best when constructed with medium-to-heavy weight fabrics, especially textured ones like acrylic and wool.

Just like the shape of the pocket itself, the flap can have straight, curved or even triangular bottom edges. It can be as wide or as narrow as desired as long as it balances well with the pocket layer underneath.

Before it is sewn to the garment surface, a pocket flap is conventionally fully lined to enclose all its raw edges. To line the flap, you can use the same fabric as the outer flap layer, or a thinner, lightweight lining fabric. When working with thick textured fabrics (like wool, for example), a lightweight lining is recommended.

A patch pocket flap is rarely constructed from a single fabric layer as this would not provide enough stability and structure. With a single layer flap, the edges are more difficult to enclose which naturally leads to a lower-quality finish.

Similar to a lined patch pocket, a lined flap can be constructed of either two separate pieces to include the lining and flap self layers, or a single fabric piece that incorporates the lining as an extension.

The latter option (lining extension) can only be used with a straight edge flap. That’s because it would be physically impossible to fold along a curved or triangular edge.

In the example below, a lined flap is added to a curved-bottom unlined patch pocket. Unlined patch pockets that have a curved bottom edge can pose a bit of a challenge when folding the bottom (curved) raw edge inwards. However, with the help of a technique called easestitching, you’ll learn how to accomplish this in one simple step.

In this case, the flap has a triangular edge, and is constructed from two separate pieces: a lining layer and a flap self layer.

Sewing The Flap And Curved Patch Pocket

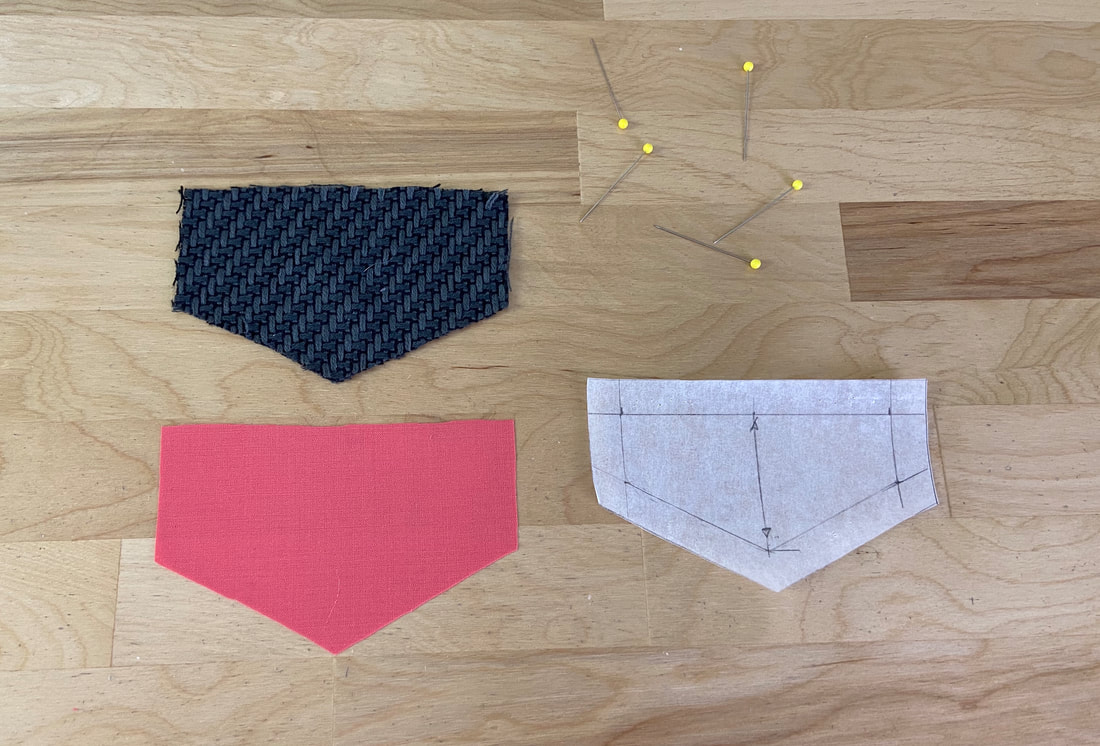

1. Cut the lining and flap layers using the same pattern. The two layers should be identical in size and shape.

2. Use the same flap pattern to cut another layer of fusible interfacing.

Trim the seam allowance along all edges of the interfacing and fuse it to the back of the flap self layer as shown.

3. Cut the patch pocket piece. This layer should have a curved bottom edge.

Set it aside for now, while we work on the flap.

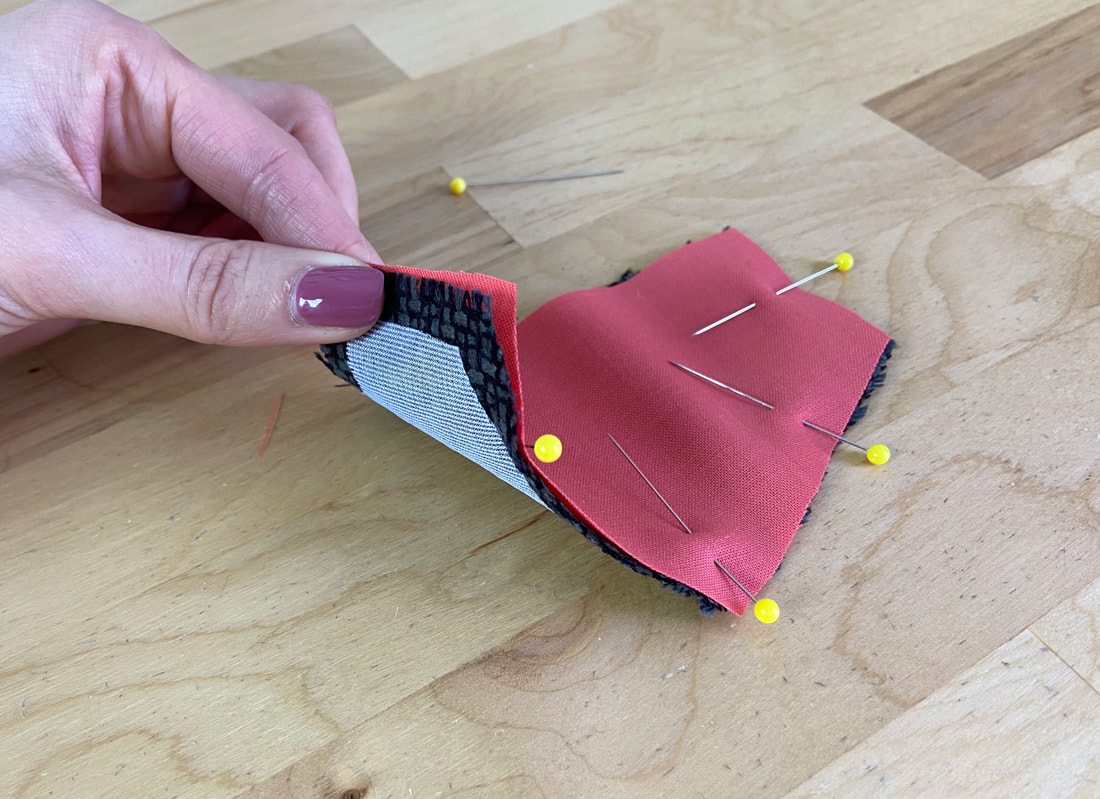

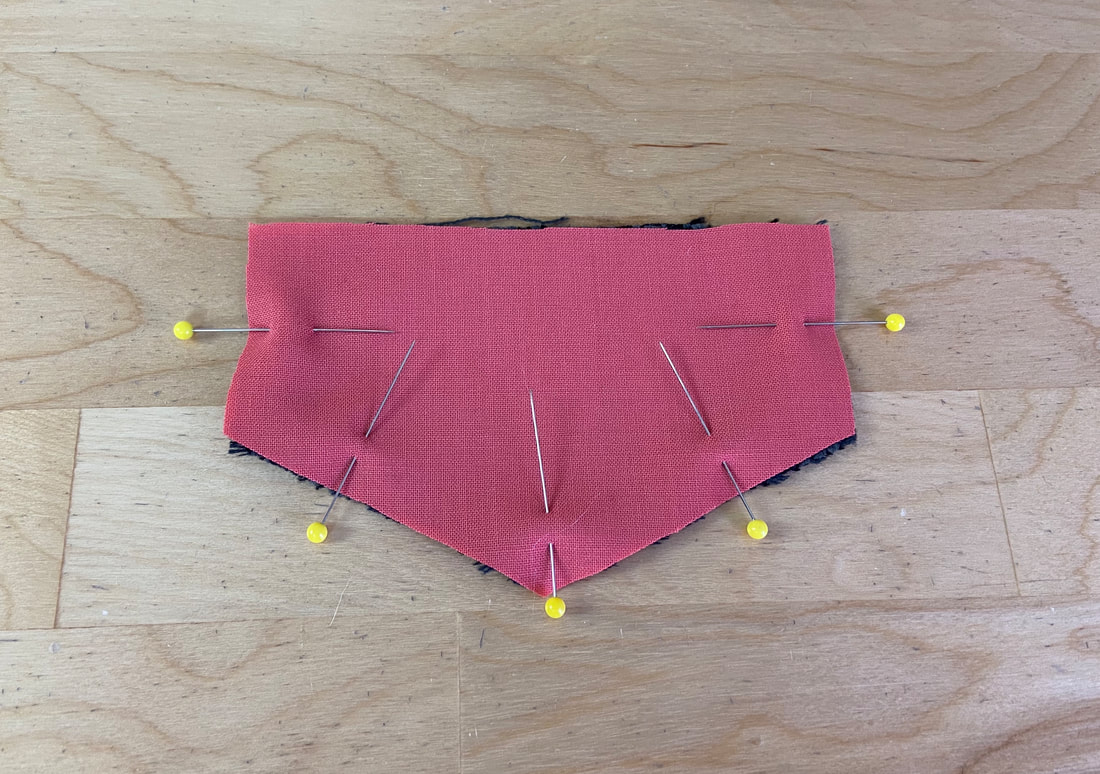

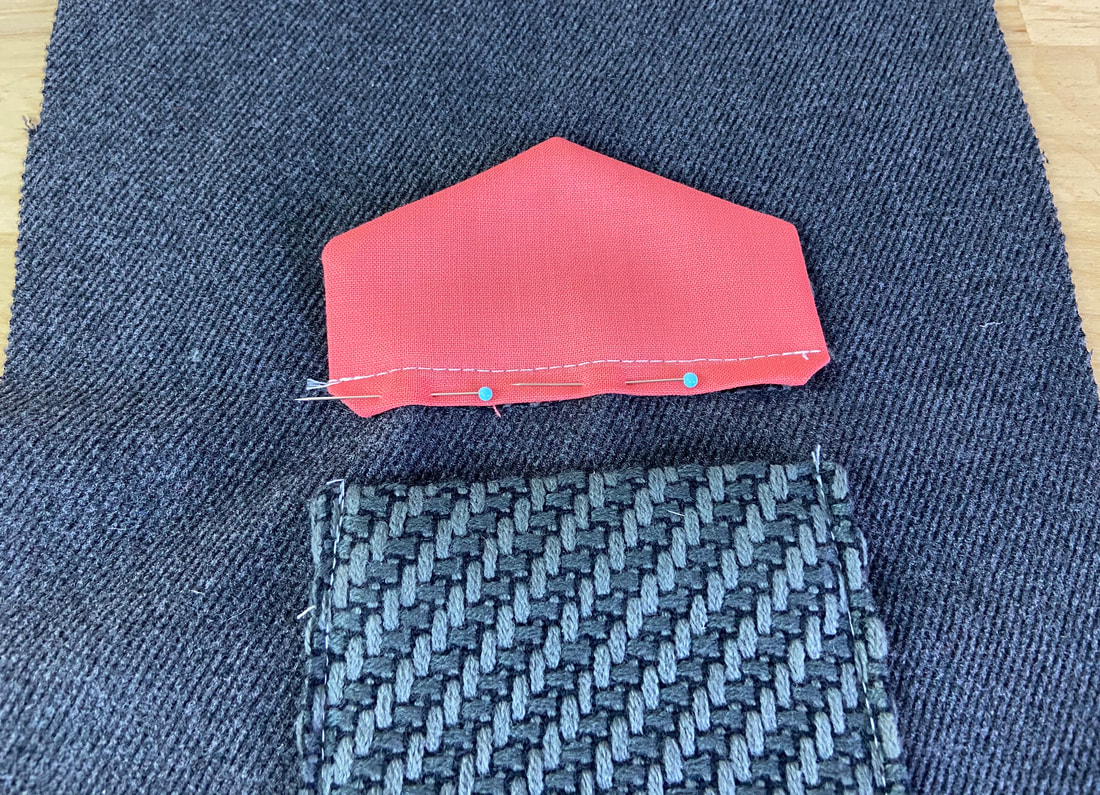

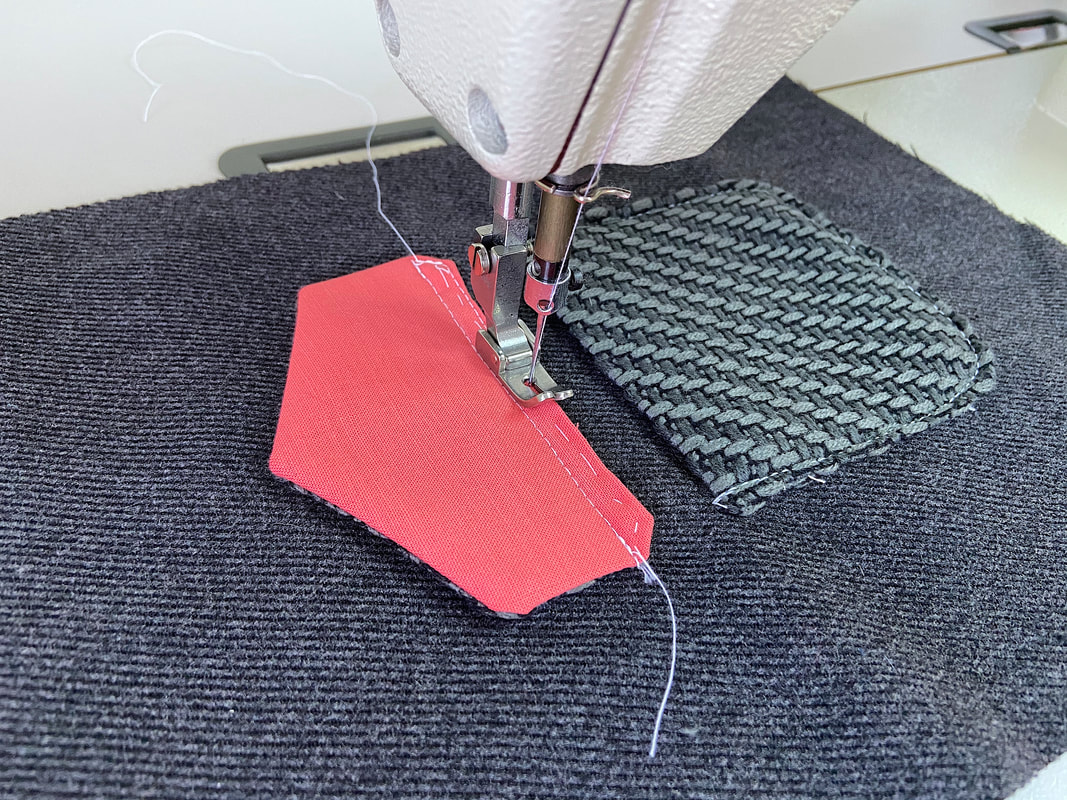

4. Align the flap lining to the flap self layer such that fabric face sides are touching and all edges align. Insert pins perpendicular to the bottom and side edges, leaving the top straight edge unpinned as shown.

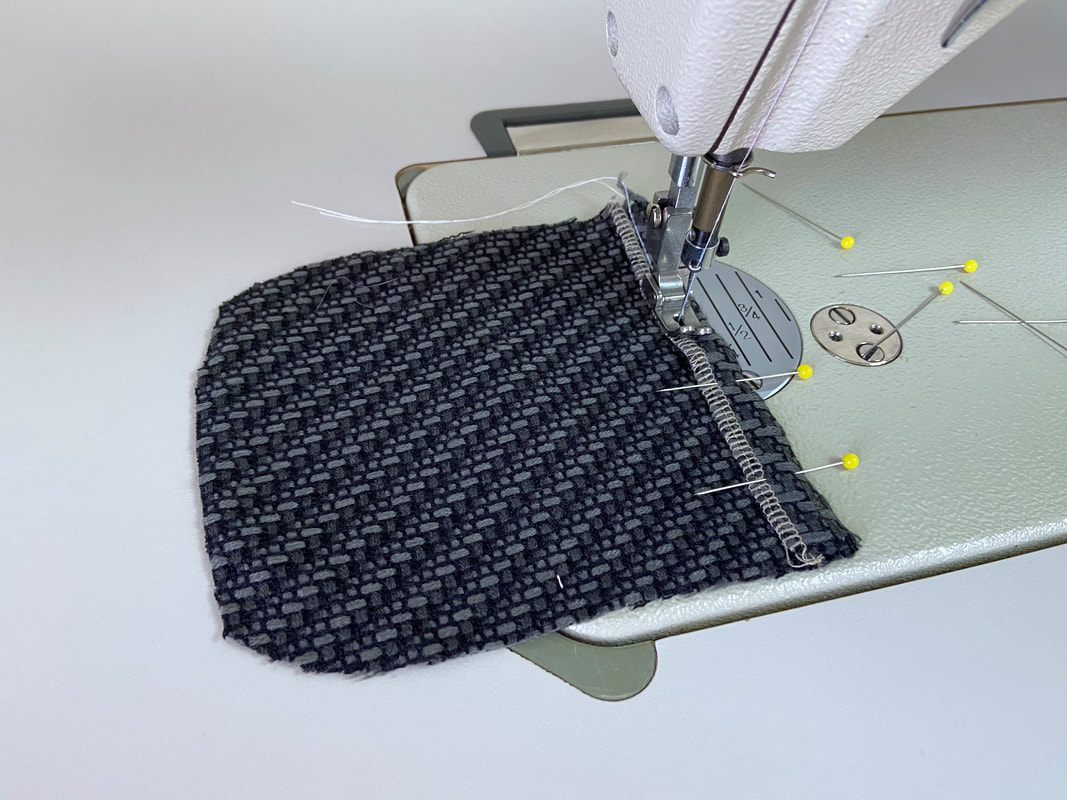

5. Leaving a ½” space from the top, stitch the flap along its triangular bottom edge, and back up the other side, stopping the stitch at another ½” from the top edge as shown.

6. Trim and notch the seam allowance to minimize bulk. In this case, the excess seam allowance is clipped at each corner edge.

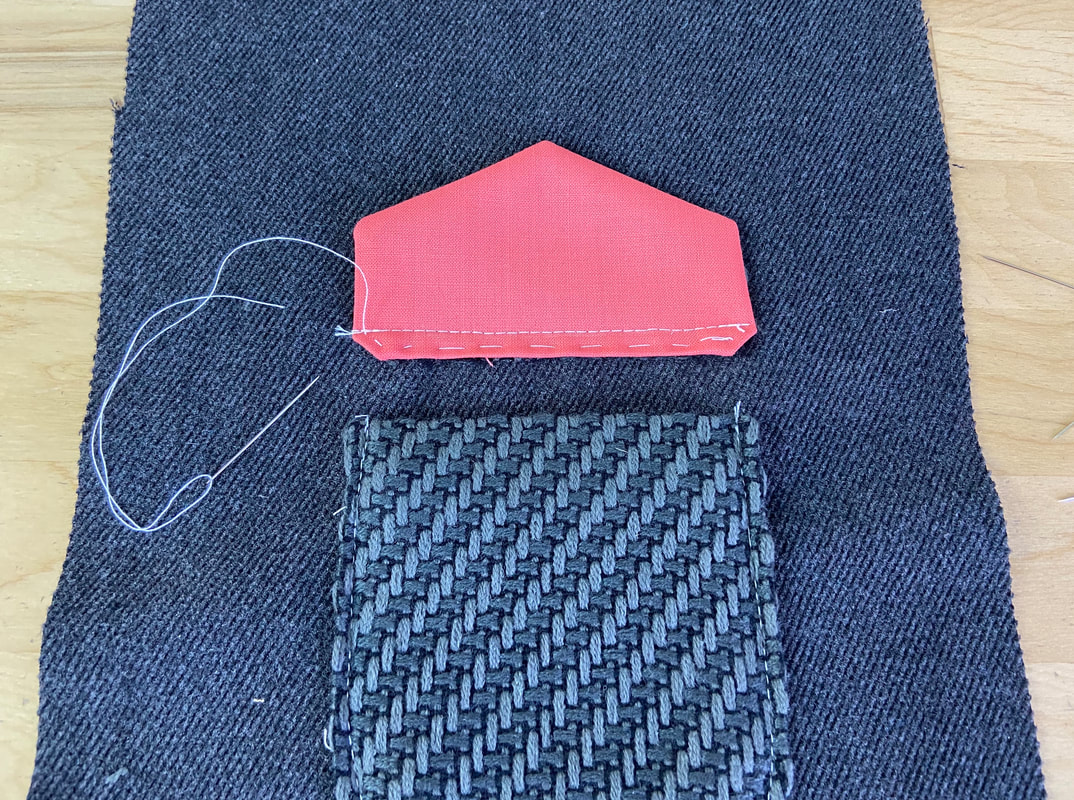

7. Turn the flap on its right side through the unstitched top opening, and iron the finished flap with the seamlines perfectly aligning to the flap’s finished edges as shown.

Set the flap aside for now while we attach the patch pocket to the garment.

8. If your patch pocket has a facing extension at the top opening edge, serge or turn the edge inwards twice, and topstitch it to enclose the fabric raw edge.

9. Fold the extension over the pocket layer with face sides touching. In this example, the extension is 1” tall. Pin horizontally on each side.

Machine stitch the sides as shown.

10. Before turning the finished edge on its right side, trim and clip the top corners to minimize bulk.

11. Turn the facing extension to its face side and align it evenly at the same distance throughout. Iron the fold to complete the pocket opening edge.

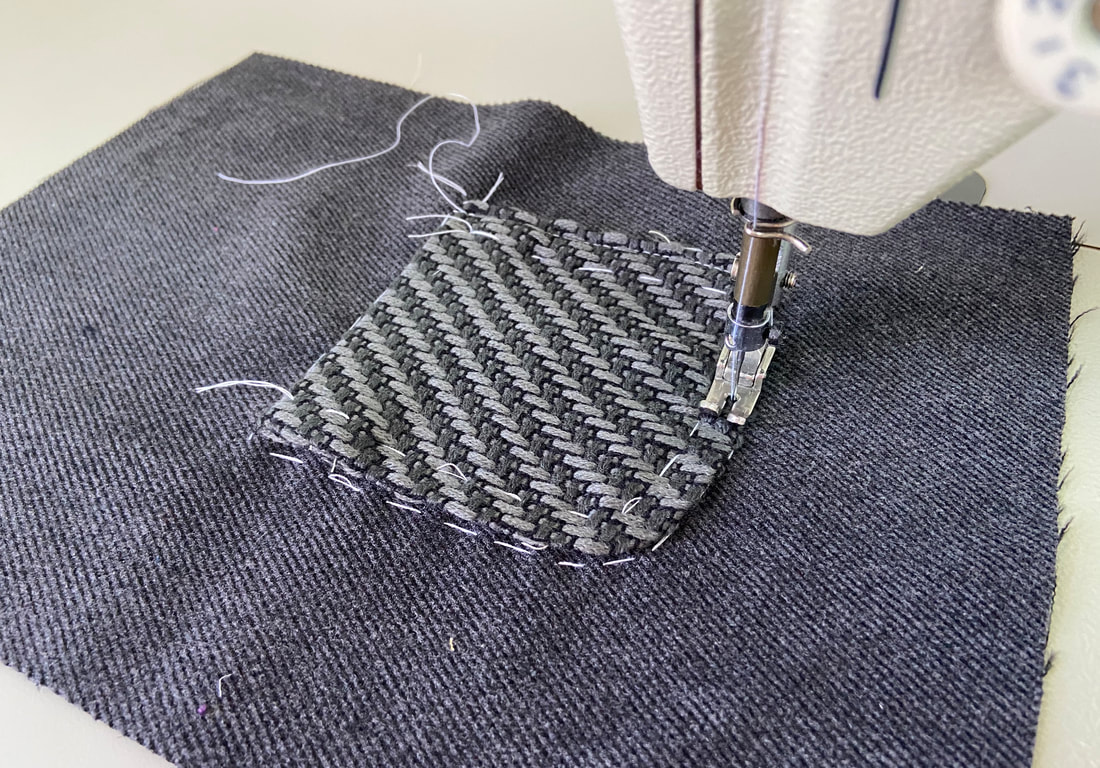

12. Apply a straight stitch along the pocket’s curved bottom edge at a little below the seamline (within the seam allowance) as shown. This is called easestitching and it will facilitate folding the curved edge inward.

13. Gently pull the loose threads of the stitch on each side such that the curved edge starts to direct upwards, toward the wrong side of the pocket.

14. Fold the edge of the pocket layer inwards with the stitching aligned right next to the bottom fold line as shown. Iron as you fold to crease the edges.

All raw edges should be folded at the designated seam allowance- ½ ” in this case. You may find it helpful to trim the curved seam allowance to ¼”. The narrow seam allowance can be controlled much easier in the folding process.

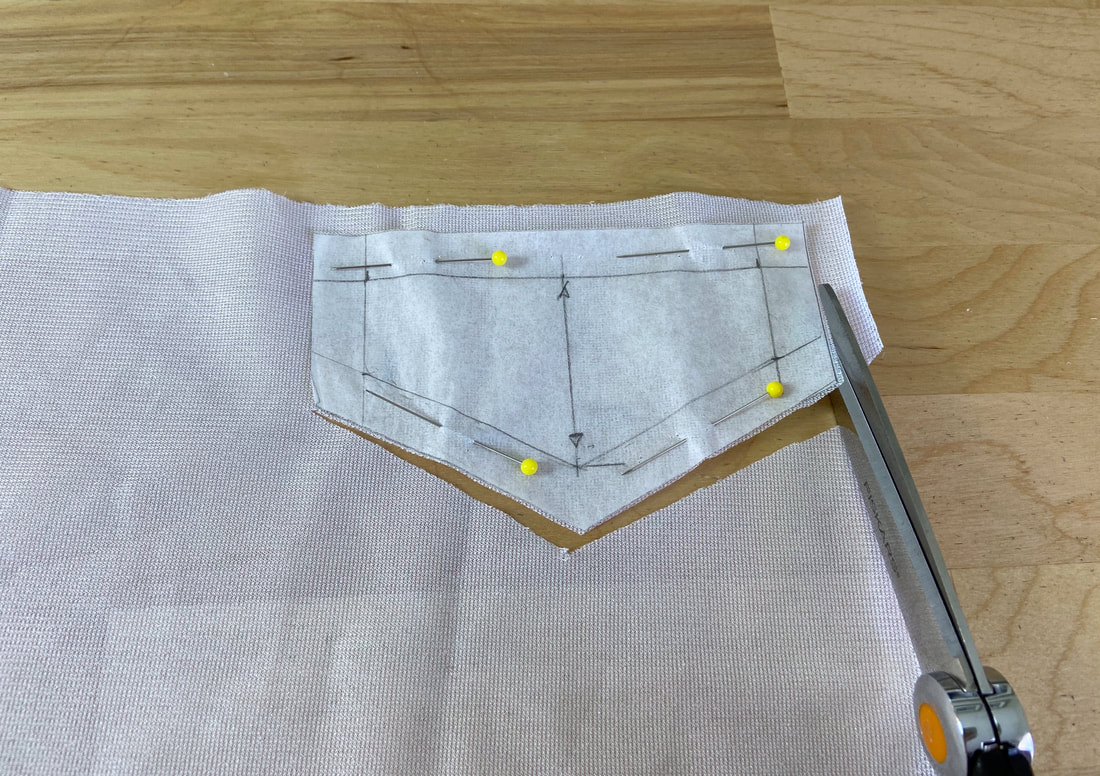

15. On the garment’s surface, hand baste an exact outline of the desired pocket shape and location.

16. Align the finished pocket layer with the basting lines and pin it to the garment layer underneath. Hand baste the patch pocket in this position.

17. Starting at one opening corner and ending at the other, machine topstitch the patch pocket as close to the edge as you can. For extra reinforcement, backstitch at both beginning and end of your stitch. Remove the hand basting once complete.

Now that the patch pocket is fully stitched, its flap can be attached.

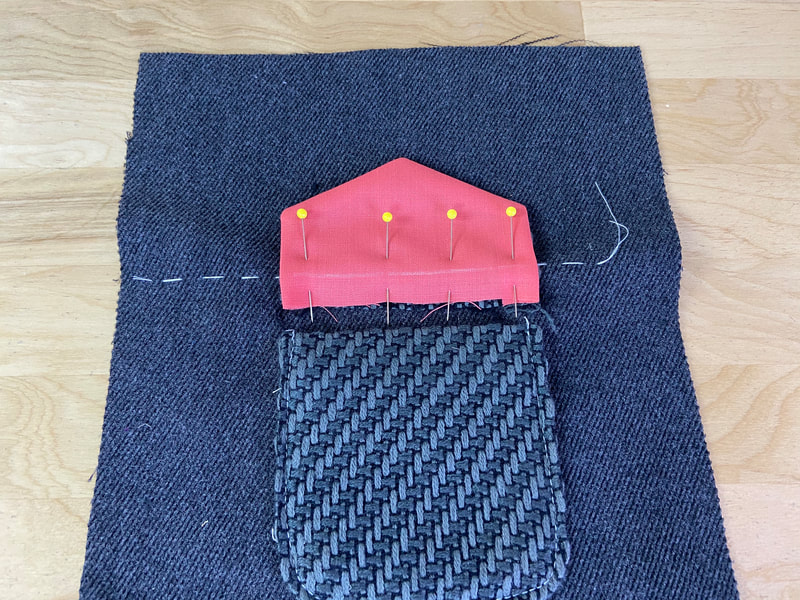

18. Mark a straight line with hand basting, parallel to the pocket opening edge, at about 1” above it as shown. Use a ruler to measure and apply the hand basting as straight as you can.

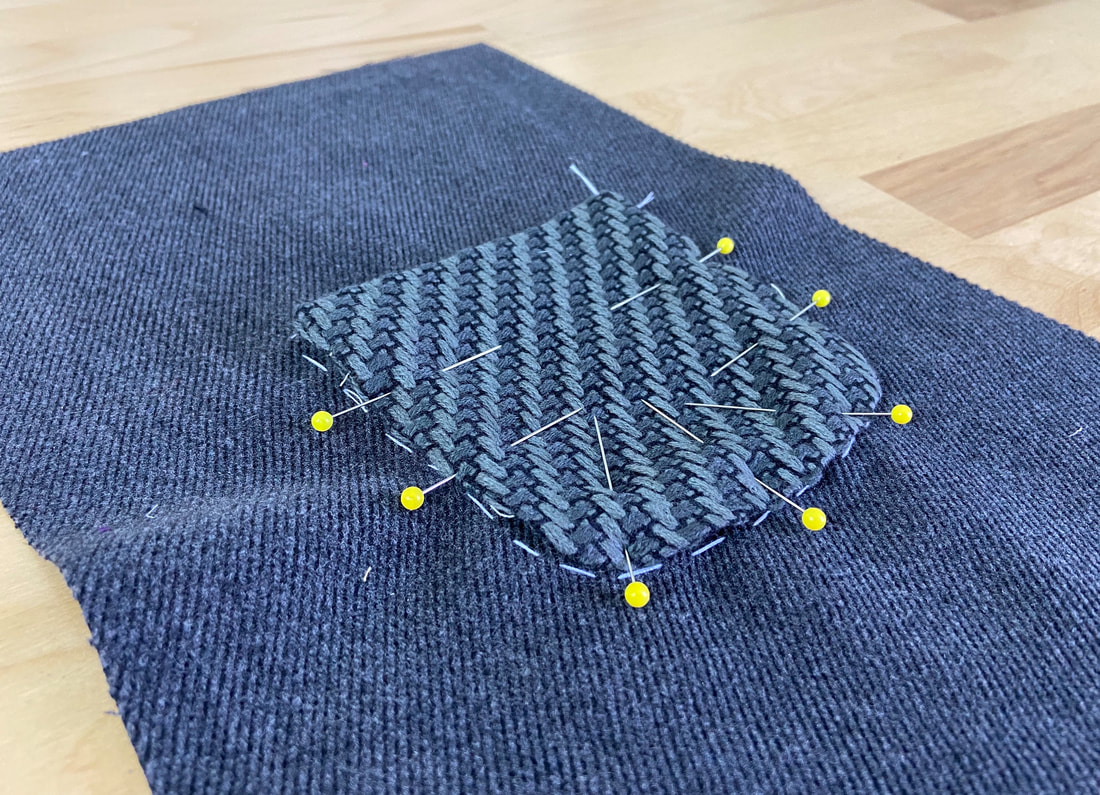

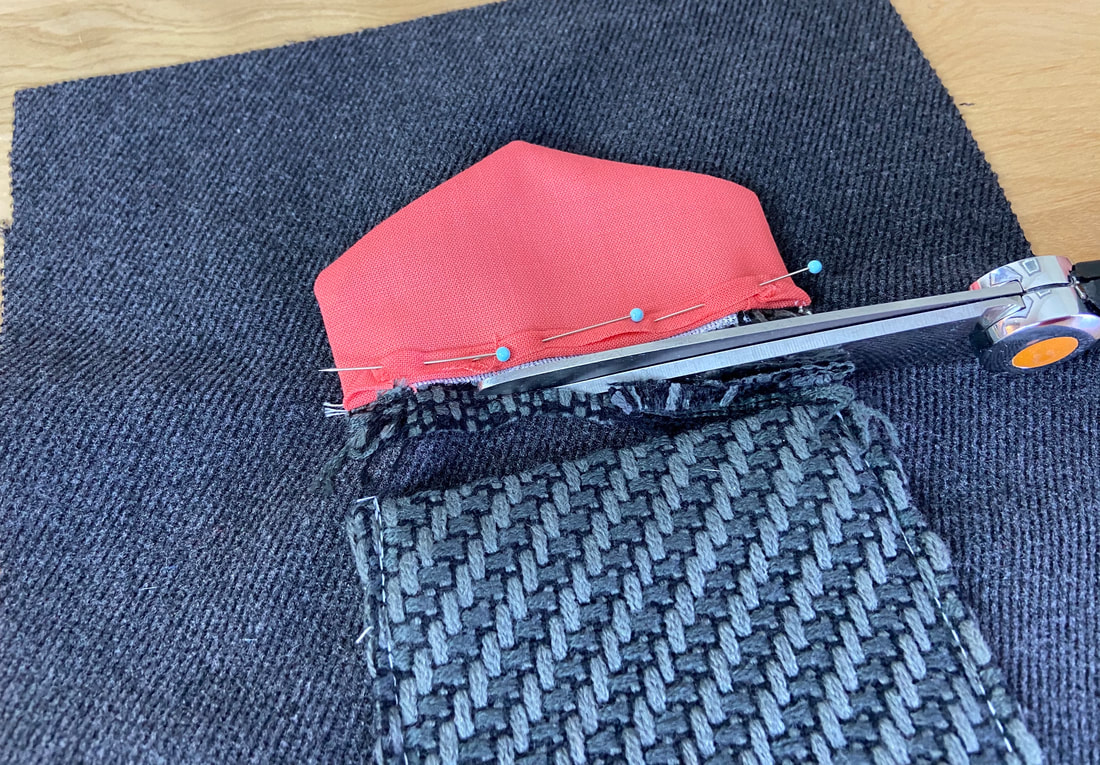

19. Align the seamline of the flap’s unstitched edge with the horizontal hand basting such that the flap and garment face sides are touching as shown. Insert pins through the flap and garment surface underneath.

To facilitate the stitching process, hand baste the flap in this position next to the seamline.

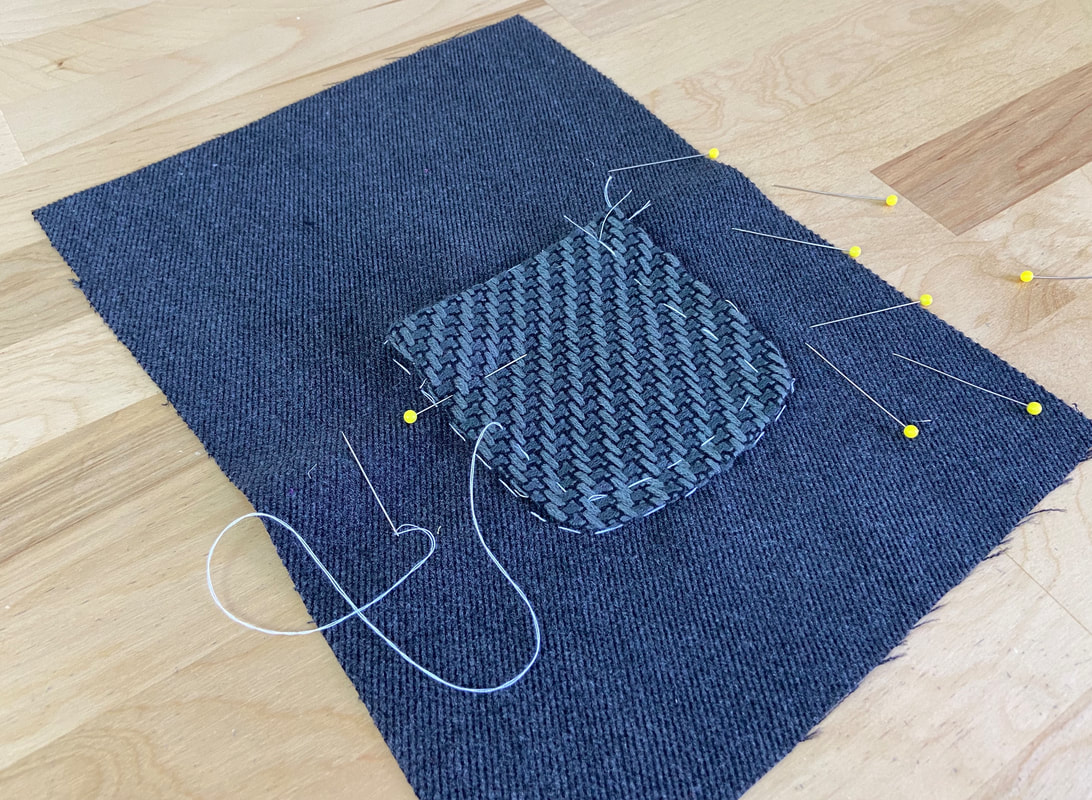

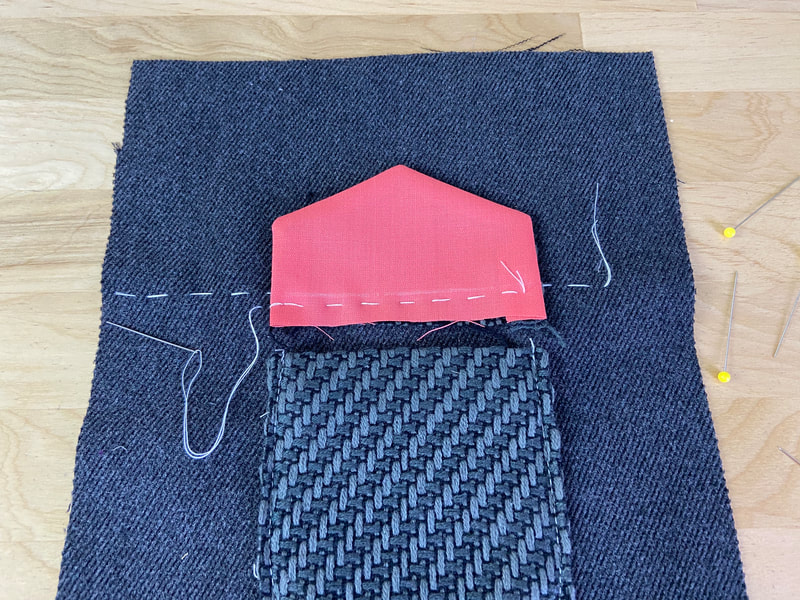

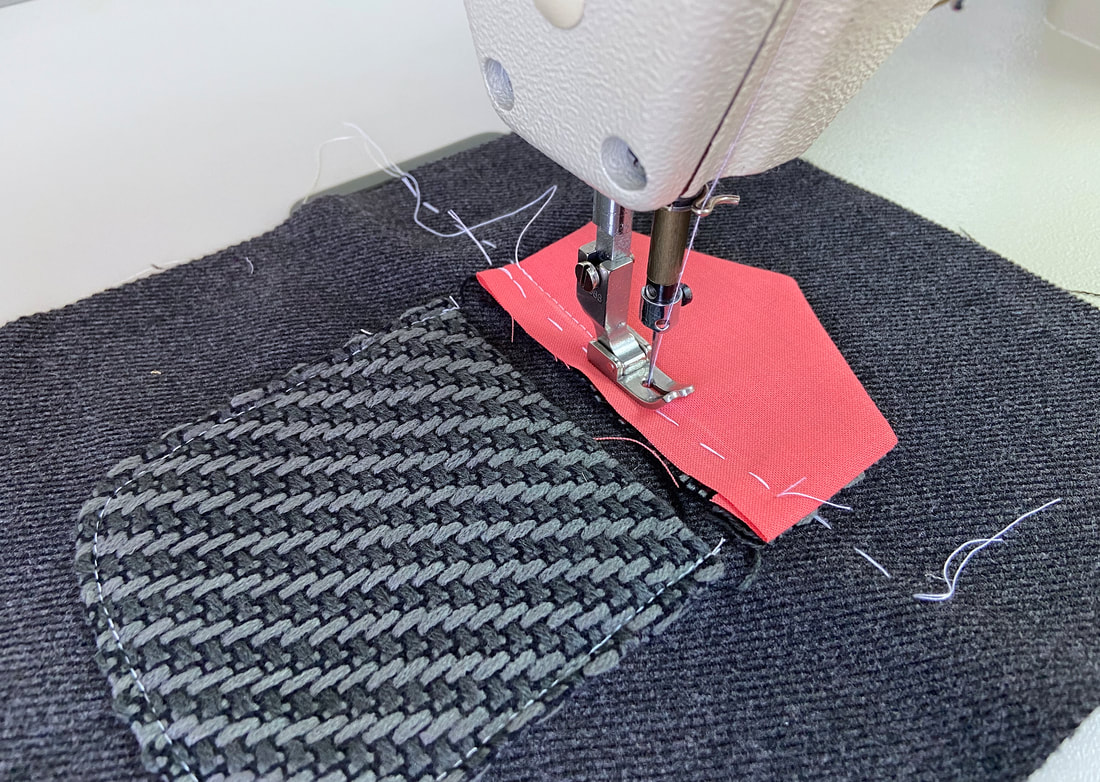

20. Machine stitch the flap to the garment layer directly on top of the seamline as shown.

Remove the flap hand basting at this point.

21. Next, fold the corner inward at each end as shown. Doing so will prevent the seam allowance from protruding out from underneath the flap. Flip the top seam allowance layer up and fold it halfway lengthwise. Iron this fold.

22. Trim the bottom seam allowance down to half its width. Trim the corners off as well. Insert a few pins to hold the top seam allowance up.

23. Place the folded seam allowance down to enclose the trimmed layer underneath. Insert pins.

24. Hand baste the folded seam allowance layer in this position.

25. Last but not least, topstitch along all edges of the seam allowance staying as close to the edge as you can. This final stitch will permanently seal and enclose the seam allowance edges.

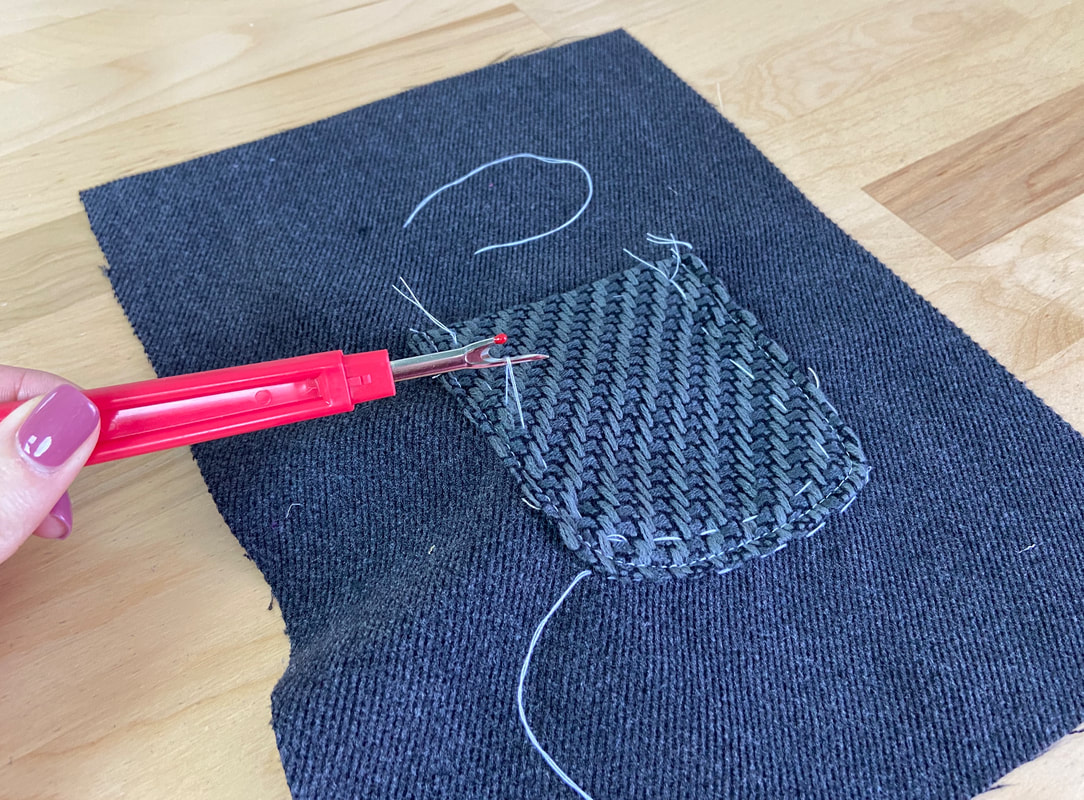

Remove all hand basting using a seam ripper.

26. Give the stitched seam allowance and patch pocket one last press. To complete the pocket application, press the finished flap layer down.

Topstitch the corners on both sides to keep the flap down.

Note: For a more decorative (and durable) finish, you can topstitch the flap edges or add an additional row of topstitching to the patch pocket layer.