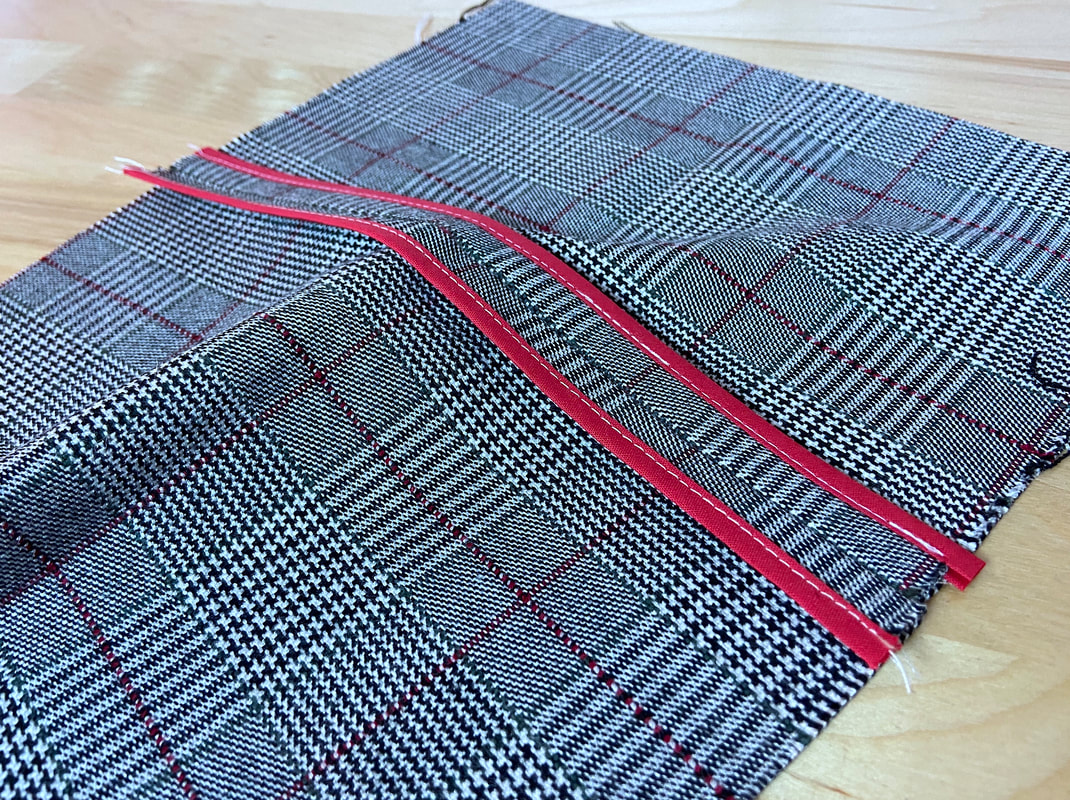

A bound seam finish is a bit more costly and time consuming as it requires the application of a separate bias binding. It does however result in a high-quality finish, perfect for heavier garments that have an exposed wrong side.

The most common application of bias-bound seams is on unlined jackets, coats and blazers. Each edge (or both edges, if needed) is enclosed by a double-folded binding strip which is usually topstitched along its folded edges.

You can purchase pre-folded bias binding at your local fabric store or make it at home using the steps in this tutorial: How To Sew Continuous Bias Binding

What is bias binding?

Bias binding is a strip of fabric that is cut on the bias (diagonally in relation to the selvage edge) then folded lengthwise three times to enclose its raw edges.

When shopping for pre-made binding you will notice both single fold and double fold options.

For the purpose of finishing seam allowance edges, double fold binding is the best choice. You can use the single fold version as an alternative but you will have to iron the binding strip one more time in order to achieve the double fold style.

The reason for cutting binding strips on the bias is that they require a certain amount of stretch and flexibility. Why? When the binding is used to clean finish curved seam allowance edges such as necklines, armholes and other curved seams, it needs to stretch enough to mold around these curvatures without straining or pulling the seams.

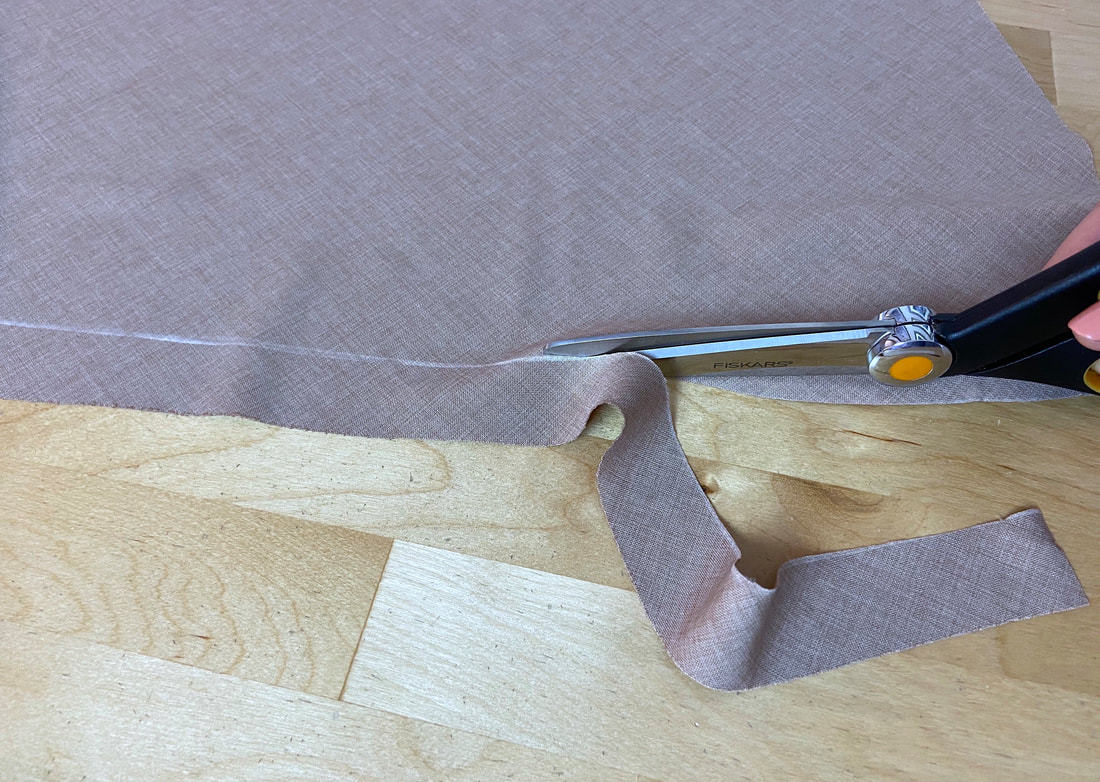

Measuring And Cutting Bias Binding At Home

As noted above, bias binding can be conveniently cut and folded at home.

To make your own binding, cut strips of fabric on the bias (diagonal to the fabric's selvage), measuring four times the width of the desired folded binding. For instance, if the final folded binding width is ¼”, then the initial unfolded width of the fabric strip will measure 1”. Use a clear plastic ruler and tailors chalk (or quilting pencil) to measure and carefully mark the strips.

Next, fold the bias strips down the middle with wrong sides touching, and iron to crease the fold line applying steam as needed.

Fold each lengthwise edge in one at a time such that they meet at the center fold line and press again.

Keeping the lengthwise edges in folded position, fold the entire binding strip in half again. All raw edges should be enclosed within this final fold.

Iron the finished double-fold binding to stabilize the creases. Consider using a spray starch to really set the folded edges. The fold lines will provide an important guide in the sewing process.

Folding strips by hand can be quite time consuming. To speed up the process, you can use a binding folding device like the one shown above. This handy tool is used in tandem with your iron to facilitate the fold-and-iron process.

Strips of bias binding can be sewn together to form a continuous strip. If you take a look at your store-bought binding, you may notice diagonal seams connecting multiple shorter strips. Working with continuous bias binding allows you to finish seams that are longer without any breaks in the binding application.

To learn how to make continuous bias binding at home, follow the steps in this tutorial: How To Sew Continuous Bias Binding

Finishing Seam Allowance Edges With Pre-Packaged Bias Binding

Method 1:

If you take a closer look at your packaged double fold binding, you will notice that one of the folded layers is a little wider than the other. This is done intentionally in order to facilitate the stitching process and minimize errors.

1. Place the folded binding around the seam allowance edge such that the shorter binding layer corresponds to the top, facing you, while the longer one is aligned underneath. The bias binding center fold should align with the fabric edge and all raw edges should be enclosed within the double-fold binding.

Depending on the fabric, binding can shift around during the machine stitching process. Regular pins will work but if you are a sewing beginner, hand basting is the best way to accomplish a more secure, accurate alignment.

3. As you align the binding, hand baste it to the seam allowance layer. Doing so will facilitate the machine stitching process to follow.

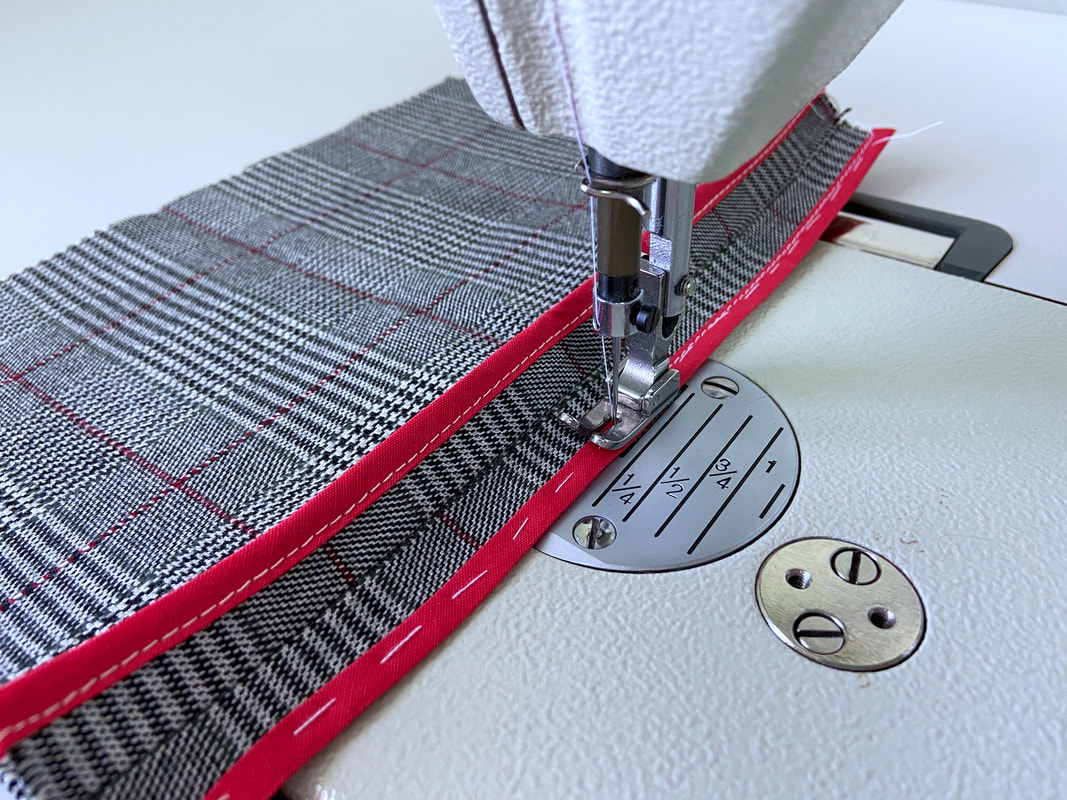

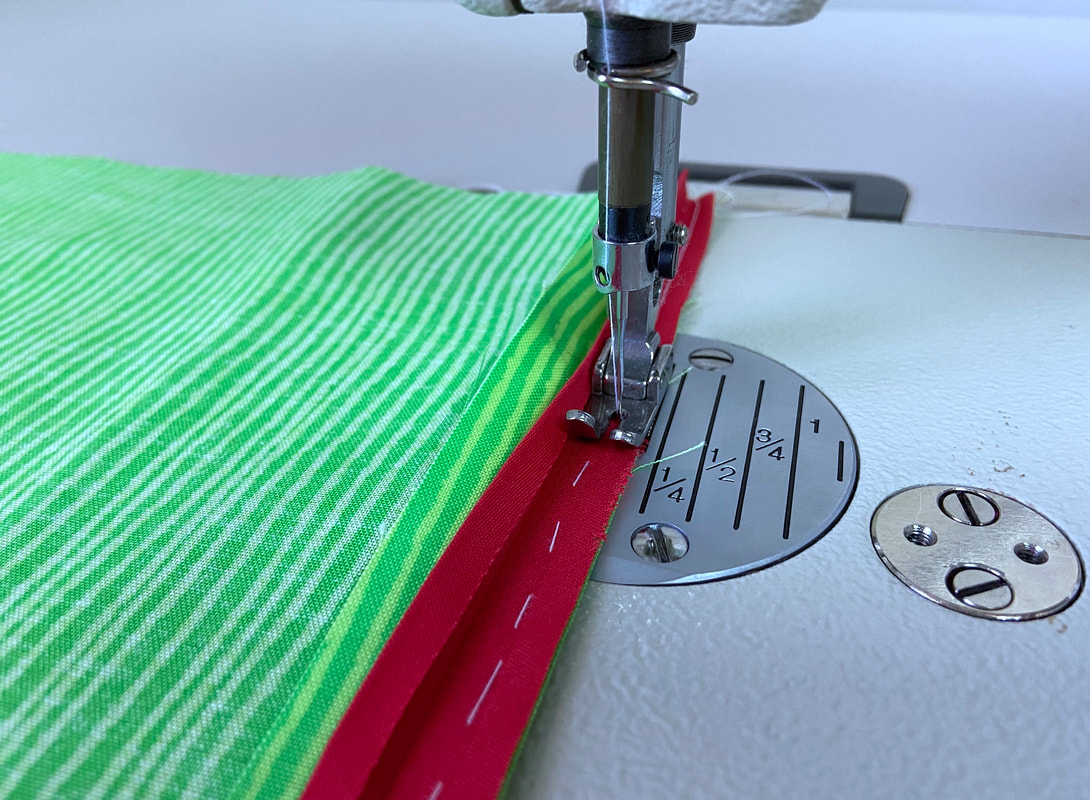

4. Once the binding is securely hand basted, machine stitch through all layers of the binding and fabric edge in between, applying the stitch right next to the biding's folded edge as show above.

Keeping the shorter binding layer on top during the stitching process will ensure that the stitch catches the longer binding layer underneath, which is not visible while machine stitching. Having it a little longer ensures that even if the binding shifts in the application process, the bottom layer is fully stitched through.

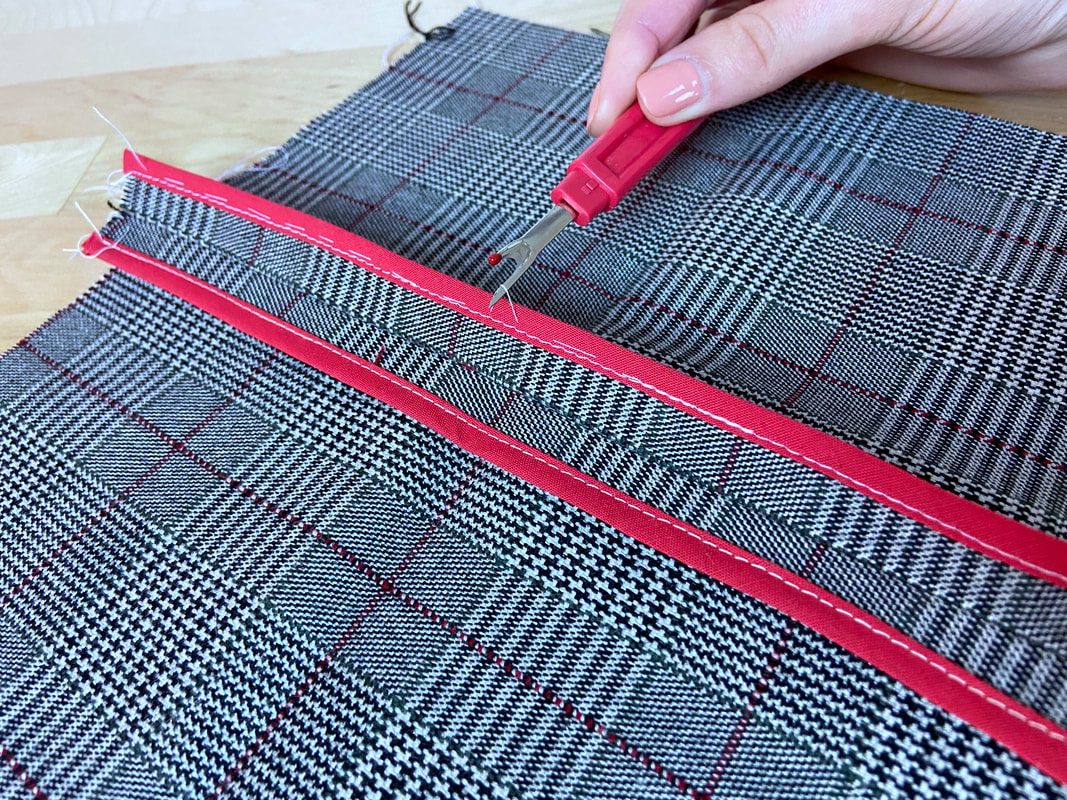

5. Using a seam ripper, remove the temporary hand basting stitches at this point.

Method 2:

Method 1 described above works great with crisp, medium-weight fabrics that are easy to handle in the stitching process. What if the binding or the fabric edge is flimsy, slippery and difficult to control?

If the binding is difficult to align in fully folded position as described above, you could attach it to the fabric edge by unfolding it and using the crease lines as a stitching guide. This method provides a bit more stability and is often the preferred choice for sewing beginners.

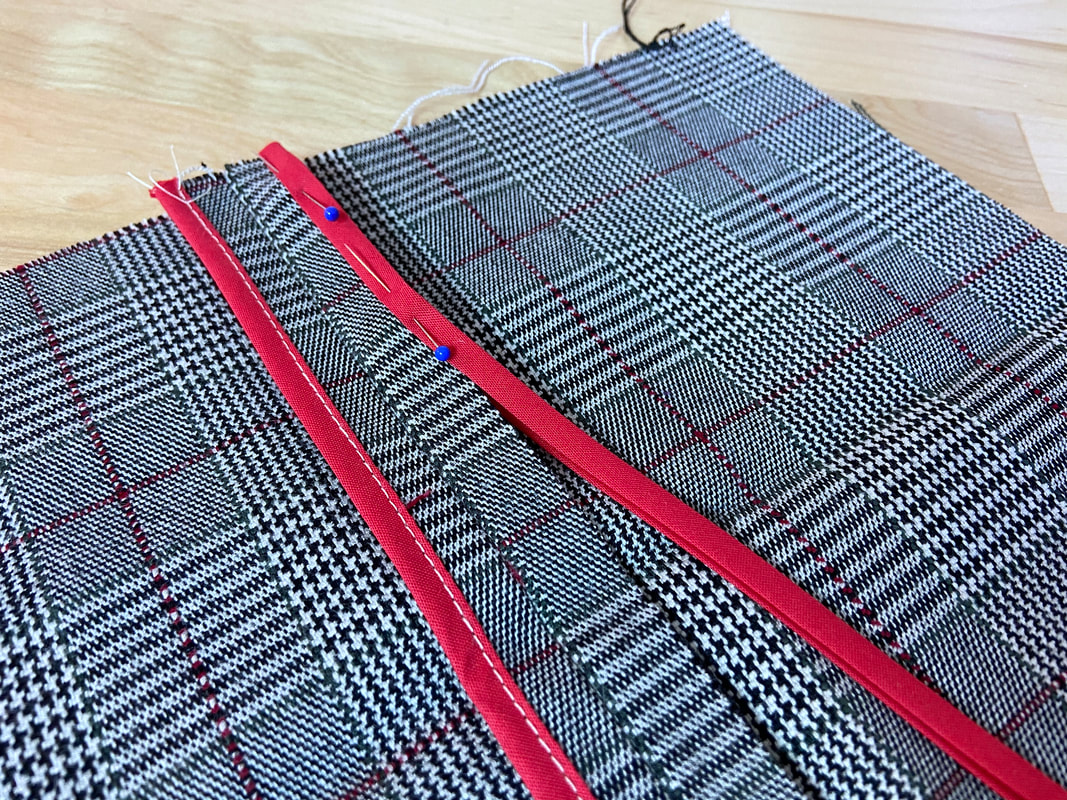

1. Unfold the binding but do not iron it open. Align one of the binding edges to the garment seam allowance edge such that face sides of both layers are touching. Insert pins horizontally through both fabric layers as you would when pinning a regular seam.

3. Hand baste the two fabric layers for added stability and stitch the two edges together with the binding facing up. Follow the closest binding crease as a guide. For best results, stitch right next to this fold line but not directly through it.

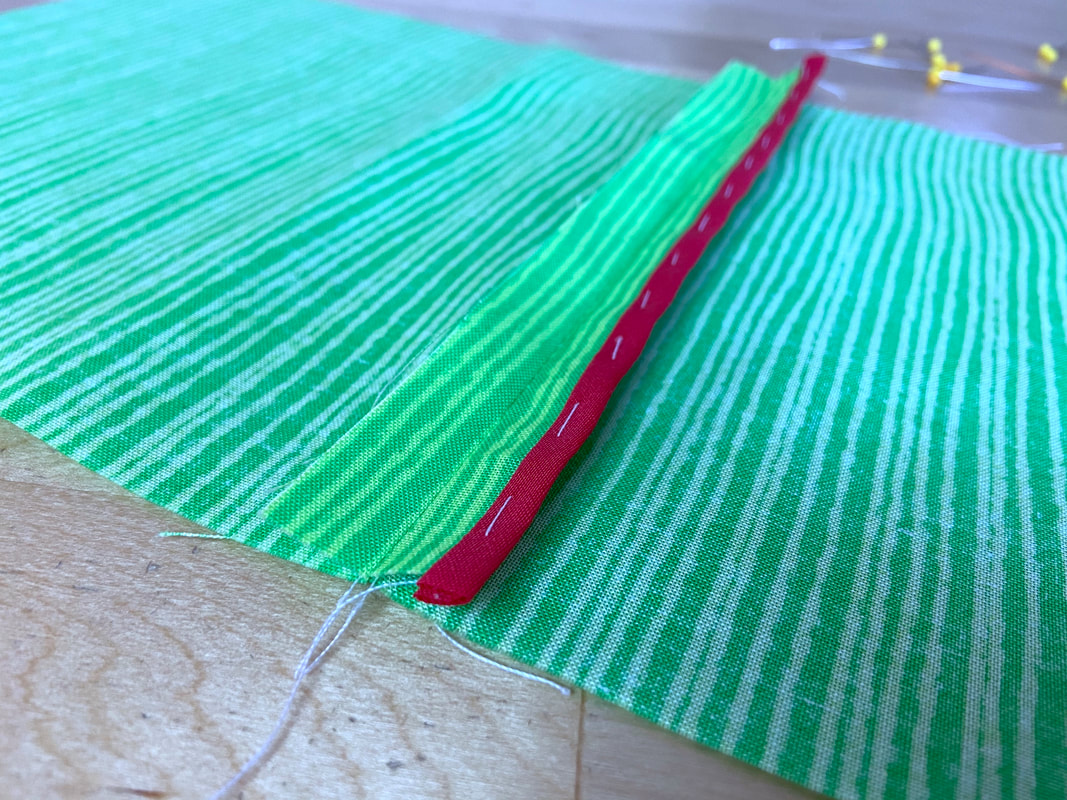

4. Once the binding is connected to the seam allowance edge, allow it to naturally fold in place and enclose all raw edges.

It is at this point that the bias binding can be topstitched closed, encasing the fabric edge.

5. Insert pins or hand baste through the binding and fabric to keep all the layers in place during the final stitching process.

6. Topstitch through all layers of the binding and fabric, next to the open folded edge of the binding as shown.

7. Last but not least, remove the hand basting using a seam ripper and iron the final binding application for a smooth, flat finish.