What Is A Shaped Facing

Regular shaped facings are great for sewing beginners as they provide practice with a few important techniques simultaneously: staystitching, understitching, applying interfacing, grading, trimming, notching and hand tacking. That is quite a lot of different sewing elements all grouped into a single sewing task!

A shaped facing is a separate unit that is exactly the same shape as the garment edge it finishes. The only difference is that a facing is the garment’s mirror image in terms of fabric face sides.

Sewing patterns for the shaped facing pieces are generated from the main garment patterns. Conventional shaped facings are comprised of separate pieces corresponding to the back, usually two identical pieces if the center back has a zipper (or other closure), and a full front piece.

For garments that have a front opening, there are certain shaped facings that blend with the garment opening and front neckline simultaneously to finish the two edges with a single facing piece.

Facings provide a smooth, clean neckline finish with no stitching visible on the face of the garment. For that reason, facings are often used with dressy, more tailored styles. Since facings provide more structure, they may not always be suitable for flowy, draped garments (especially those that are more casual in nature).

Interfacing The Facing Pieces

The garment and/or the facing have to be interfaced for extra stability prior to the facing being attached.

If your pattern set does not provide separate interfacing patterns, use your facing patterns to cut out the interfacing portions.

If you are working with fusible interfacing, make sure you cut the pieces such that the adhesive side corresponds to the wrong side of each facing or garment (depending on where it is added).

Once the interfacing pieces are cut, trim all the edges down to ½” or the seam allowance length- your patterns should specify which.

Conventionally, interfacing backs the garment layer thus it is attached to the wrong side of the area that will house the facing. However, depending on the fabric, you may choose to add interfacing to the facing layer instead. This is true especially in cases where the garment fabric is thicker and more structured than the facing. In this instance, the facing needs extra reinforcement so that it lays flat and doesn’t roll to the outside of the neckline edge.

In some rare cases, you may need to add interfacing to both garment and facing layers. This is especially true when the interfacing is very thin, and the facing and garment fabrics are flimsy and need extra structure along the neckline.

For a garment that has a back zipper, as is very common with neck facings, the interfacing shouldn’t extend into the zipper placket but rather stop at the center back seamline. If your interfacing is lightweight and doesn’t add bulk, it is ok not to trim the interfacing edges. Sometimes, extending the interfacing past the seamline into the zipper seam allowance can provide an extra layer of stability for lightweight, flimsy fabrics.

Sewing A Round Neck Facing With Center Back Zipper Opening

In the steps below, you will learn how to sew a regular shaped facing to a curved neckline using two different methods of finishing the facing ends to the zipper tape: One is hand-stitched (most traditional), the other is completed by machine (fastest).

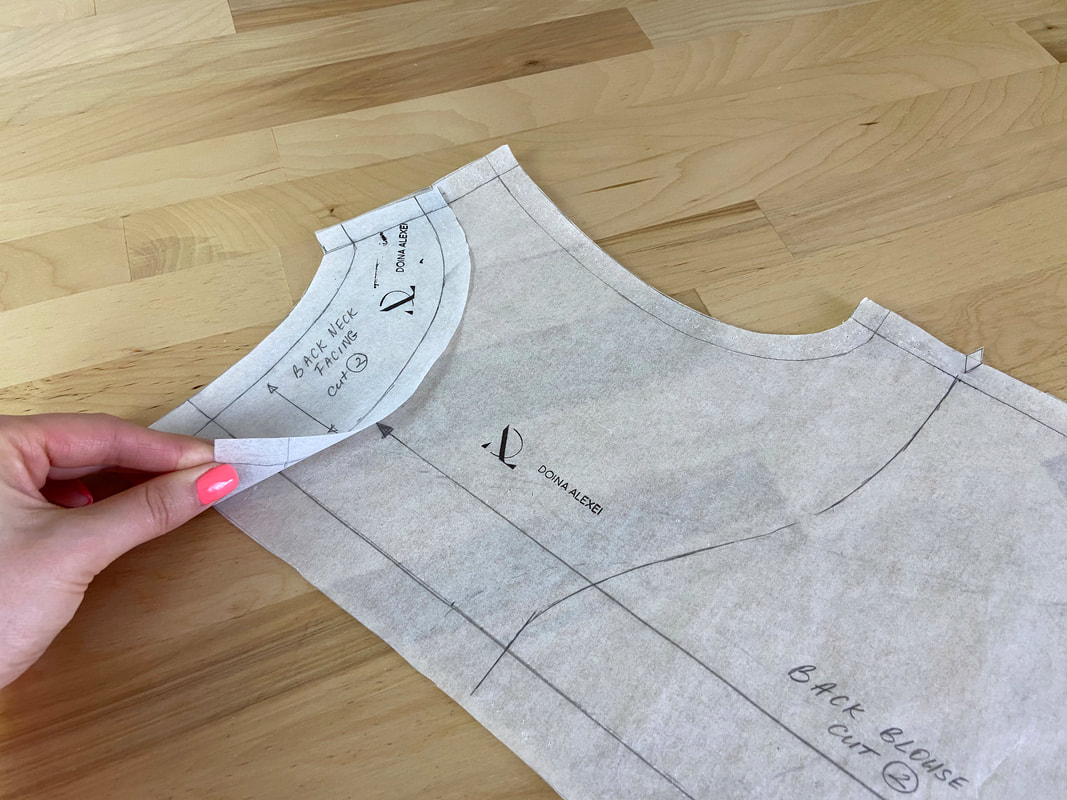

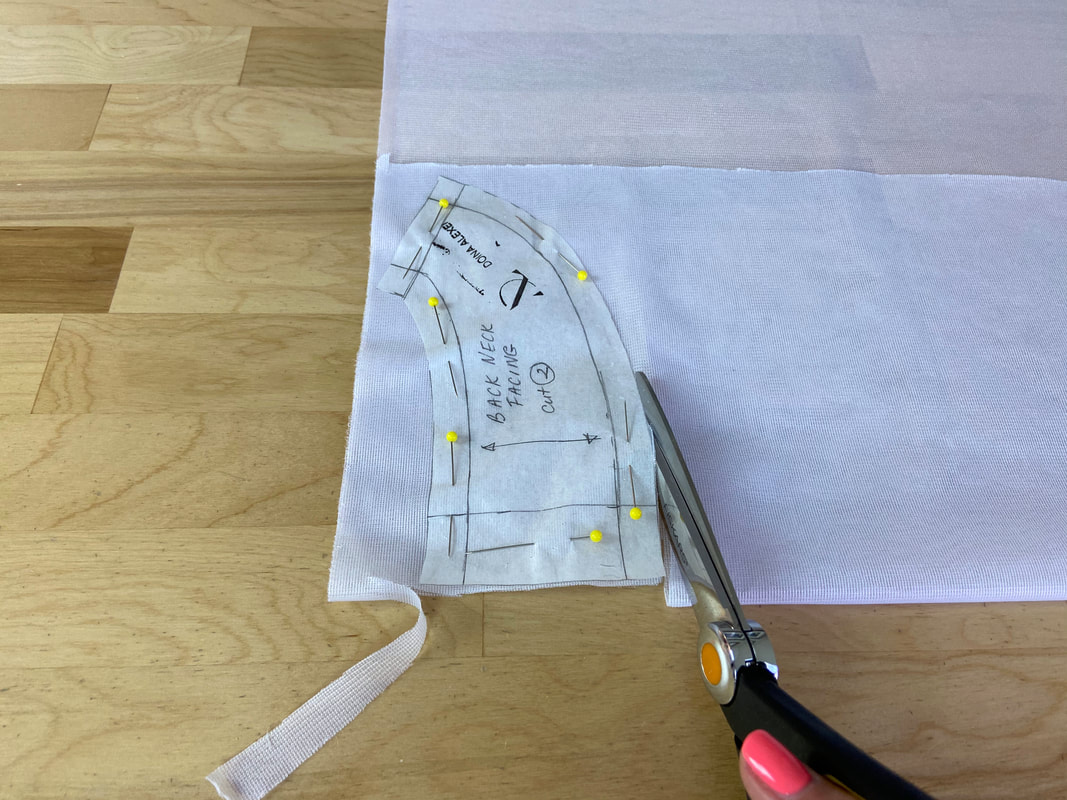

1. Cut out all your facing and interfacing pieces first.

This facing has two identical (mirror image) pieces for the back and one full piece for the front neck. You should have one pattern for the front and one pattern for the back pieces.

The two back portions are cut by folding the fabric and cutting through both fabric layers at once.

If your pattern set does not provide separate interfacing patterns, use the neck facing patterns to cut them out using the method described above.

If working with fusible interfacing, treat the adhesive side as the “right” side in the cutting process.

2. Trim the interfacing down to ½” along all edges.

3. Assuming you are using fusible interfacing, center each interfacing piece on the wrong side of each garment piece and make sure the adhesive side is touching the fabric. Using a protective cloth, iron on top of the interfacing to fuse the two layers together.

Before moving on to sewing the seams, it is important to first staystitch the garment neckline and the facing neckline edges.

Staystitching is applied at about ¼” from the edge of the neckline in, within the seam allowance, to stabilize the curved edges and prevent them from stretching or losing their shape during the construction process.

Staystitching is applied particularly along neckline and armhole edges as these are curved and thus most vulnerable to unwanted stretching. Similarly important is staystitch the facing pieces.

More info on staystitching in this tutorial: Staystitching

4. Now that the neck facing pieces are prepped, align them at each shoulder. Match each front shoulder seam edge to each corresponding back shoulder seam edge such that fabric face sides are touching. Insert pins perpendicular to the edges as shown. Depending on your comfort level with your sewing machine, you may need to hand baste for extra stability.

5. Stitch the shoulder seams at the designated seam allowance- ½” in this case. Backstitch on both ends of the stitch for extra reinforcement.

6. To minimize bulk, trim the seam allowance edges about halfway down (1/4” in this case).

7. Open the seam allowance edges and iron them in open position. Iron from the wrong side of the seam as shown.

8. At this point clean finish the facing outer edge with the finishing technique of your choice. To find the best option, check out these facing edge finishing methods: Finishing Facing Edges

In this tutorial, bias binding is used. The bias binding strip is applied along the entire outer edge of the facing. The outer edge is always longer and should have no notches. The inner, shorter facing edge is sewn to the garment neckline.

9. Now that the outer edge is clean finished, the facing can be aligned and stitched to the garment's neckline.

To start with, it is important to consider whether the zipper has been sewn in yet. You can apply the facing both before and after the zipper has been inserted. However, applying the zipper first is highly recommended as it tends to facilitate the construction process.

In this tutorial, the invisible zipper has already been sewn into the center back seam.

10. Align the facing staystitched edge (inner, shorter edge) to the garment neckline edge such that the fabric face sides are touching. First, match all the shoulder seams, then all notches (if any), then the rest of the edge.

As you match the facing edge to the neckline, insert pins perpendicularly to keep the alignment in place.

11. When you arrive at the zipper opening:

For the hand slipstitched method: Wrap the facing edges around the natural position of the zipper. This technique works for all zipper styles.

For the machine stitched zipper finish: Open the center back folded edges housing the zipper, and match the end of each facing portion to its corresponding zipper opening edge as shown.

This technique works for zipper application where the center back edge can be extended outwards fully- Invisible zippers or exposed zippers are best examples in this instance.

12. Hand baste the facing to the garment neckline edge above the seamline, staying within the seam allowance.

13. Machine stitch the two layers together carefully following the appropriate sewing machine seam allowance guides- ½” in this case. Backstitch at both ends of the stitch and remove the basting once complete.

14. Trim the seam allowance down and grade it if needed.

Grading is the technique of trimming the facing seam allowance shorter than the garment in order to eliminate extra bulk.

Grading may not always be necessary if you are already working with light fabrics that don’t accumulate bulk. Be careful not to trim or grade the seam allowance too close to the stitching or you risk weakening the finished neckline edge, especially if the fabric is loosely woven and frays a lot.

Equally important (if not more important) is notching the seam allowance throughout to release tension.

15. Cut wedge clips into the seam allowance edge but be careful not to cut too close to the actual stitching or you risk weakening the neckline edge.

To further minimize bulk, cut the seam allowance excess diagonally at the corners.

Notch the corners regardless of which zipper facing finish you are using (hand or machine stitched).

16. From the garment's face side, iron all the seam allowance layers pointing away from the garment as shown. It will be easiest to iron this portion over a tailor’s ham or a sleeve board.

17. Next, understitch at approximately 1/8” away from the seamline through the facing and seam allowance layers underneath. This stitch (known as understitching) will prevent the facing from rolling to the outside of the garment, as well as keep the neckline laying smooth and flat.

18. Turn the facing on its right side and iron the finished edge carefully. You may need to use a sleeve board or tailor’s ham if you have them.

To finish the facing ends to the zipper by hand: Turn the facing toward the inside of the garment, aligning it in its natural position. Open the zipper and fold in the facing end. Pin each facing end to each zipper tape portion.

To complete, slipstitch through the facing folds and zipper tape layers.

You can learn how to apply a slipstitch here: Hand-Applied Blind Stitches

To machine stitch the facing ends (invisible zipper example): Keeping the facing on its wrong side, align each facing end to its corresponding garment center back edge such that the zipper tape is sandwiched in between and fabric face sides are touching. Insert a few pins perpendicularly to secure this alignment. It is also extremely helpful to hand baste for extra security.

Switch your machine presser foot to a zipper presser foot, and stitch the edges together next to the zipper teeth. Be very careful not to catch the zipper coils in the process.

Turn the facing on its right side and press the finished neckline edge carefully. Again, it is easiest to use an ironing add-on like a tailor’s ham or sleeve board.

Note: Trim the corner excess seam allowance before turning the facing application on its right side.

Note: Trim the corner excess seam allowance before turning the facing application on its right side.

Last but not least, it is equally important to secure the facing layer to the inside of the garment. To achieve this, hand tack the free-hanging facing edge to the garment seam allowance at each intersecting seam.

19. Turn the garment on its wrong side and match the corresponding facing and garment shoulder seams. Pin through each seam to secure.

20. Using a regular whipstitch or a cross tack, stitch to connect the facing edge to the garment seam allowance layer (only) at each shoulder seam.

The addition of the cross tacks will maintain the facing's correct alignment throughout the garment's life cycle.