Learning how to sew begins with sewing a simple straight seam.

While this is truly the simplest task in dressmaking, and a great way to get started, there are some basic rules that should be followed in the process. Luckily, once you understand these standard sewing “rules”, you can apply them to sewing any type of seam, regardless of shape or seam allowance width.

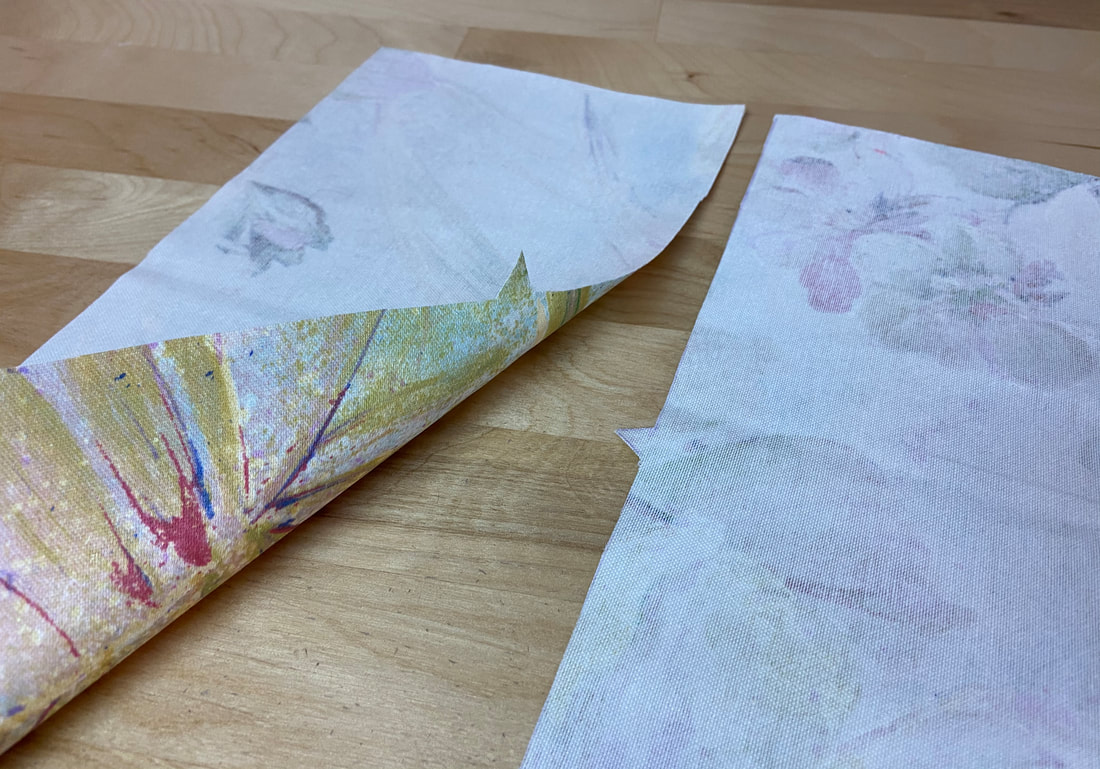

Before you begin the sewing process, make sure all your notches and other sewing notations are transferred from the patterns to your fabric pieces. It is also important to distinguish between the fabric’s right and wrong as this will be imperative in the seam alignment process.

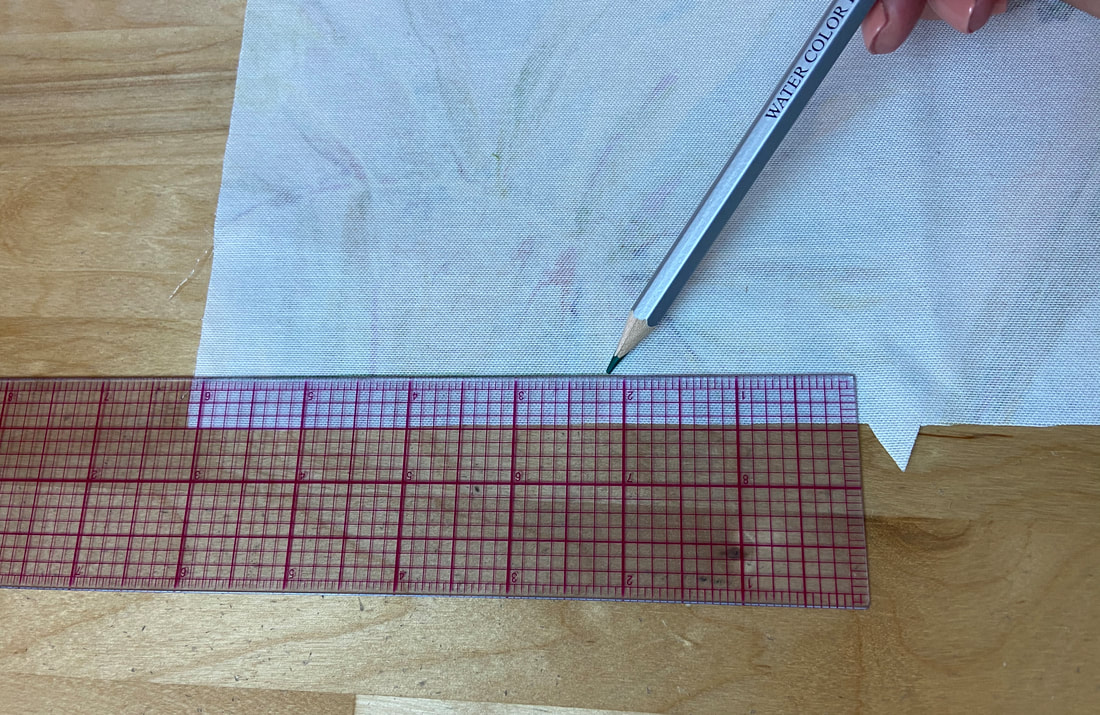

If you are reading this tutorial, you are most likely at the beginning stages of learning how to sew. For that reason, it is a good idea to also transfer all seamlines from you patterns to your fabric pieces. The marked seamlines provide a stitching line as well as help you identify the proper seam allowance without having to go back to your sewing patterns for reference.

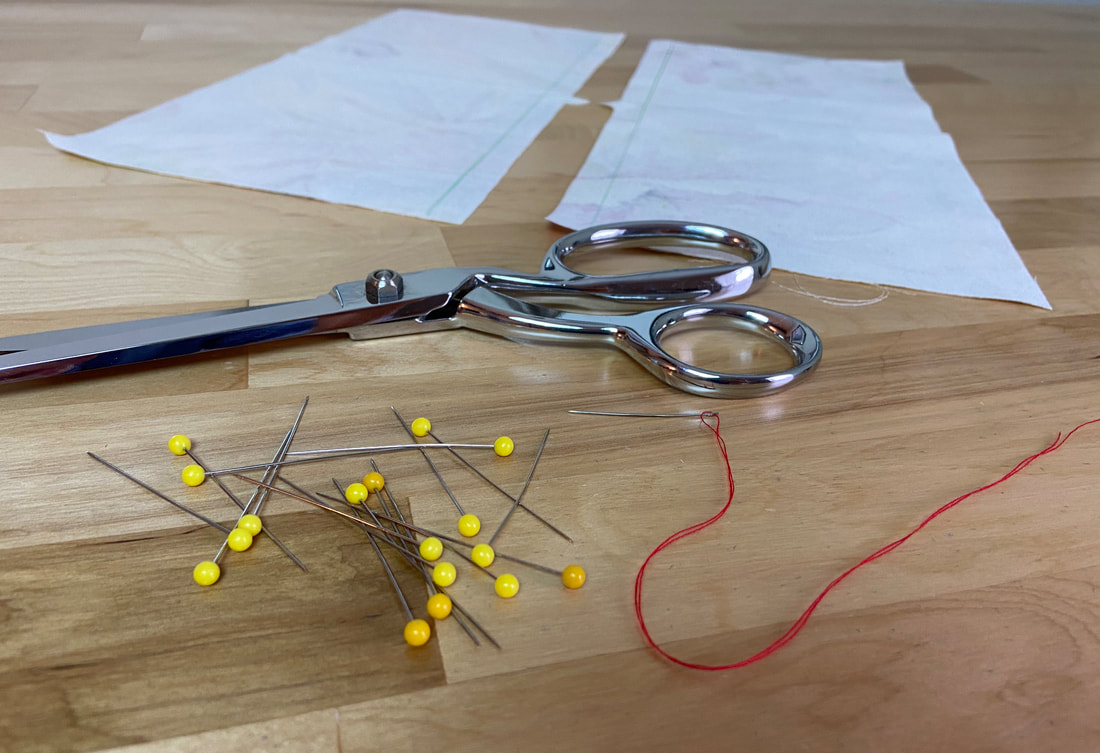

You will need a set of ball-head pins (recommended), a good pair of scissors, and of course, your sewing machine.

If you want a little theoretical background on seams and seam allowance, check out this tutorial: The Basics of Seams and Seam Allowance. It will walk you through some basic concepts on seams and seam allowance, and help you understand the seam alignment, stitching and clean finishing process.

Note: Don’t worry about seam allowance finishes quite yet. This tutorial will only focus on stitching and properly ironing the seam once stitched. Seam allowance finishing techniques are discussed in this section: Seam Finishes

Sewing A Straight Seam

1. Find the matching seam edges based on notches and other markings. These should have been transferred at the pattern marking stage.

2. Place the fabric pieces on top of each other such that the face sides are touching and the notches are perfectly aligned. If the fabric pieces have any other markings that should be aligned, check that these are also matched appropriately.

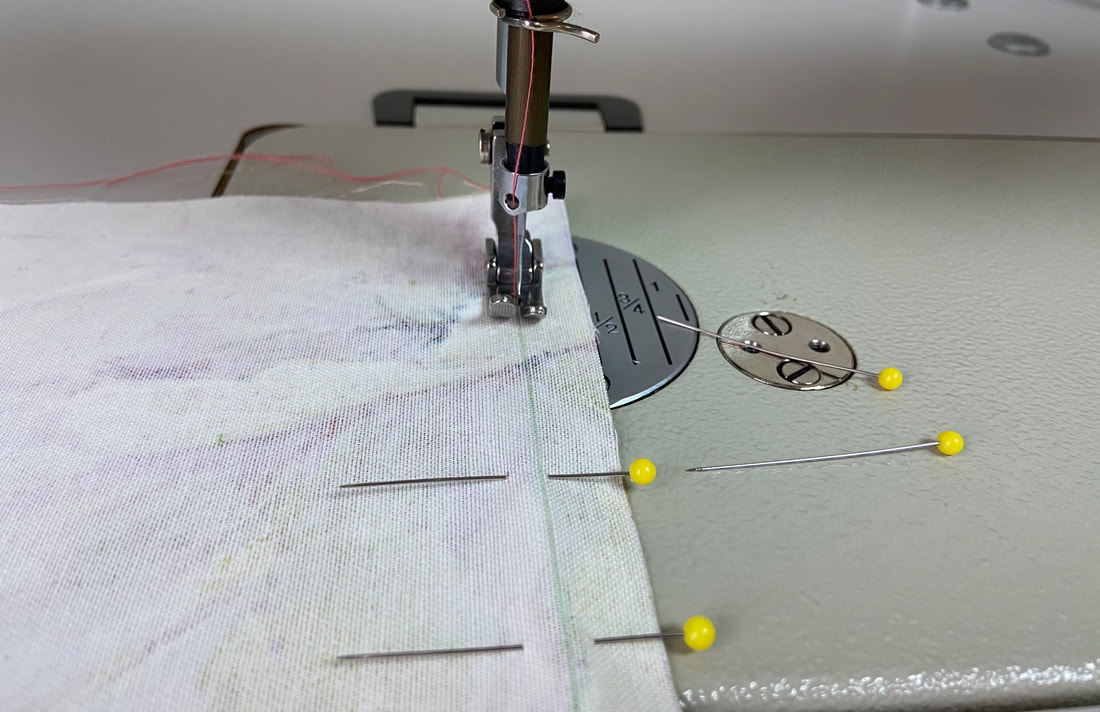

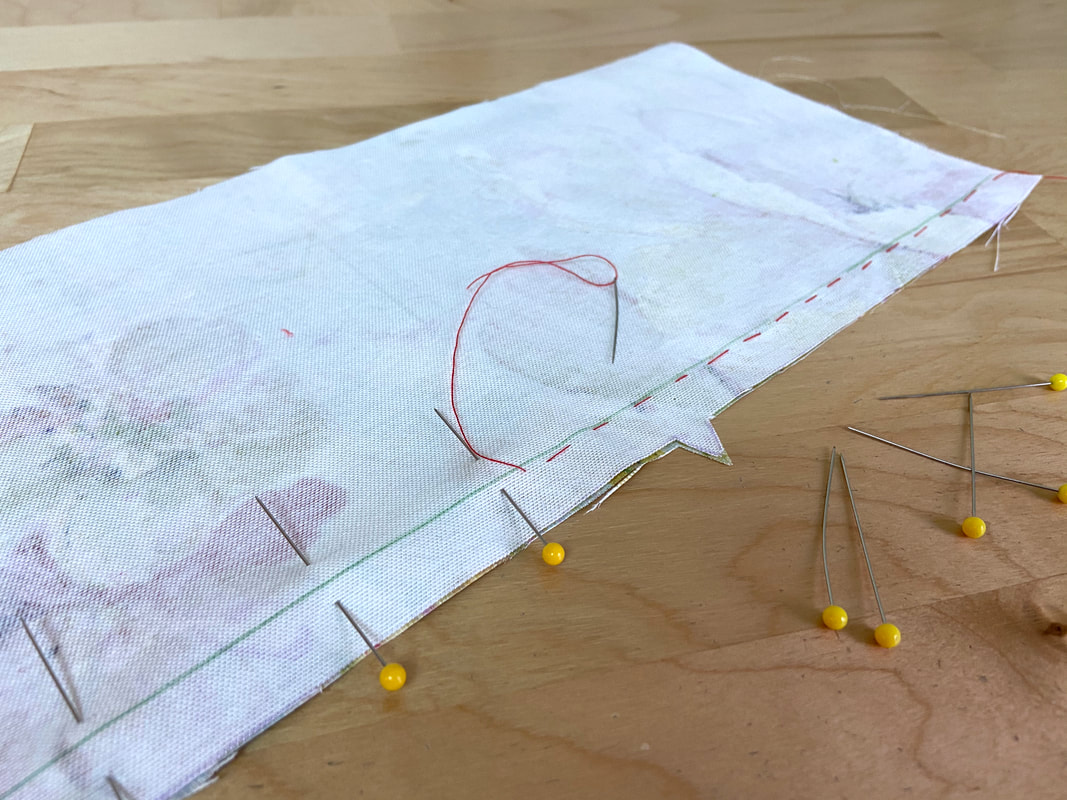

3. To hold the two fabric layers in place, insert pins horizontally, perpendicular to the edge, with the pin needle point facing inwards as shown.

If your fabric is structured and easy to handle, you may insert as many pins as you feel will be enough to keep the edges properly aligned. If working with slippery, difficult-to-handle fabrics, insert pins more densely (closer to one another) for increased control.

4. If you already feel comfortable with your sewing machine, you may stitch the seam using pins as the only stabilizing technique. Make sure to remove the pins as you approach them. Never stitch directly through pins!

The horizontal alignment of the pins, with the ball point facing outwards will make the process of removing them very safe and easy in the machine stitching process.

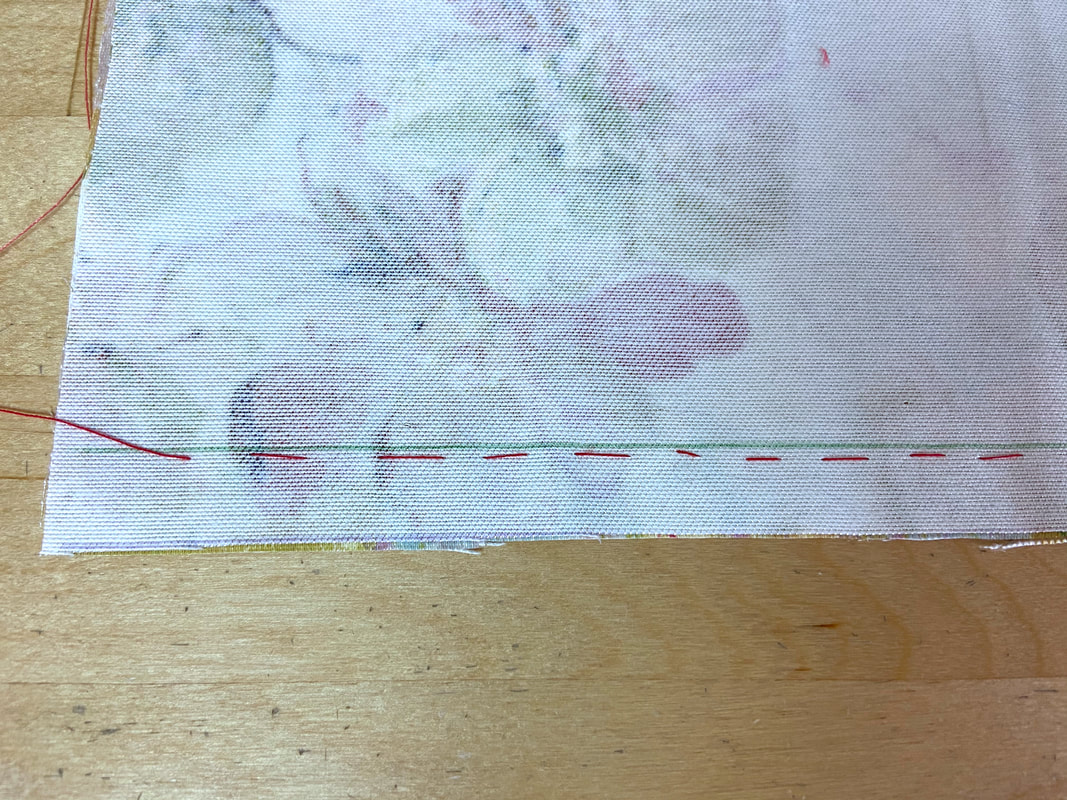

5. In case you are not altogether comfortable machine stitching a seam held together only by pins, apply an uneven hand basting stitch prior to machine stitching. Doing so will keep the fabric layers securely aligned and easy to handle. As you baste the seam edges, remove each pin as you approach it. The goal is to replace the pins with hand basting.

Apply the hand basting stitch right next to the seamline and not directly on top of it. Doing so will facilitate removing the temporary basting when no longer needed.

Hand basting fabric layers prior to stitching is not limited to sewing beginners. When working with slippery, thin fabrics like various types of silks and polyesters, it is extremely helpful to hand baste seams and difficult-to-stitch areas prior to machine stitching them. In these cases, pins alone do not provide enough stability. Although it will take a little extra time, hand basting is essential for a smooth sewing process with less errors and a garment that is always professionally constructed.

Learn more about various hand basting techniques in this tutorial- Hand Basting: A Complete Guide

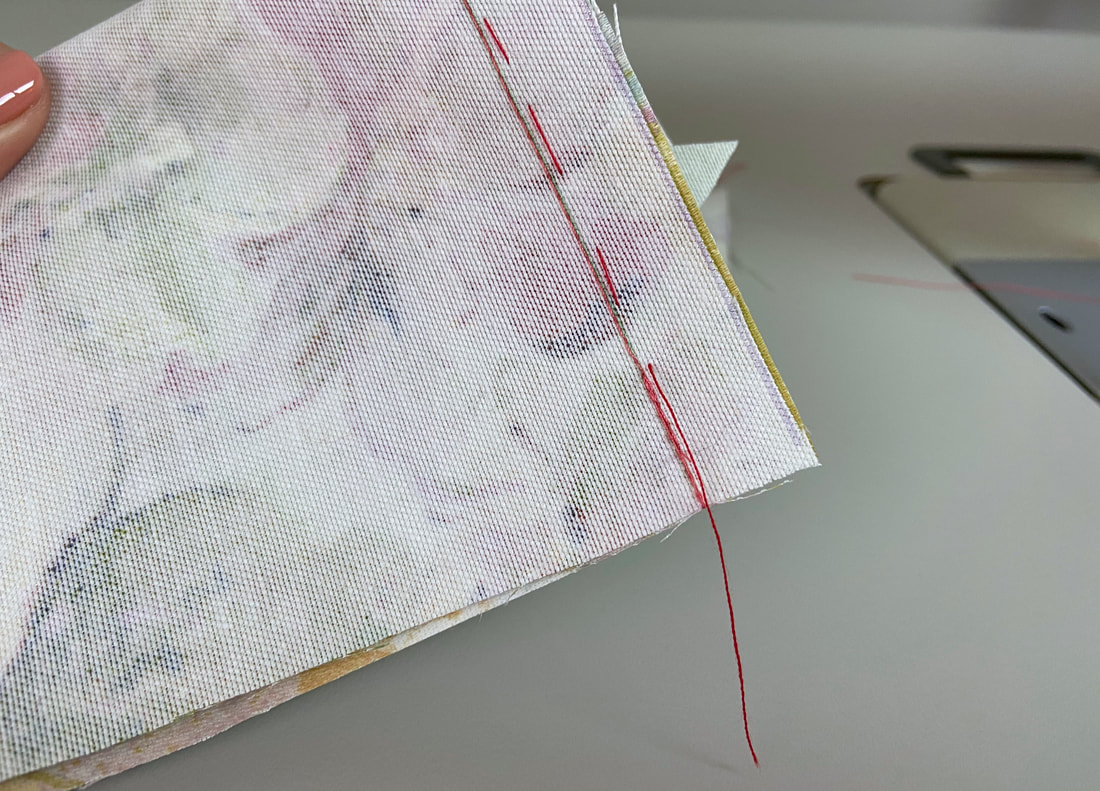

6. To machine stitch the straight seam, place the two fabric layers under the presser foot and drop the needle in at about ½” away from the seam’s top edge. This will allow you enough length for backstitching.

7. Using the backstitching feature on your sewing machine, stitch backwards to the top edge of the seam then forward to stitch the rest of the seam.

8. As you stitch, follow the marked seamline (if you transferred it from your pattern) carefully and make sure the fabric edges are continuously aligning with the appropriate seam allowance guide on your machine. Stitch right next to the basting and not directly through it. Doing so will help you remove the basting thread much faster.

9. When arriving at the bottom of the seam, backstitch at ½” backwards and then again forward to secure the stitching.

Note: If you notice the stitch has some tension due to the fabric’s thin structure, do not backstitch at the end of the stitch. You can use the non-backstitched end to release tension and any seam wrinkles through it in the ironing process below.

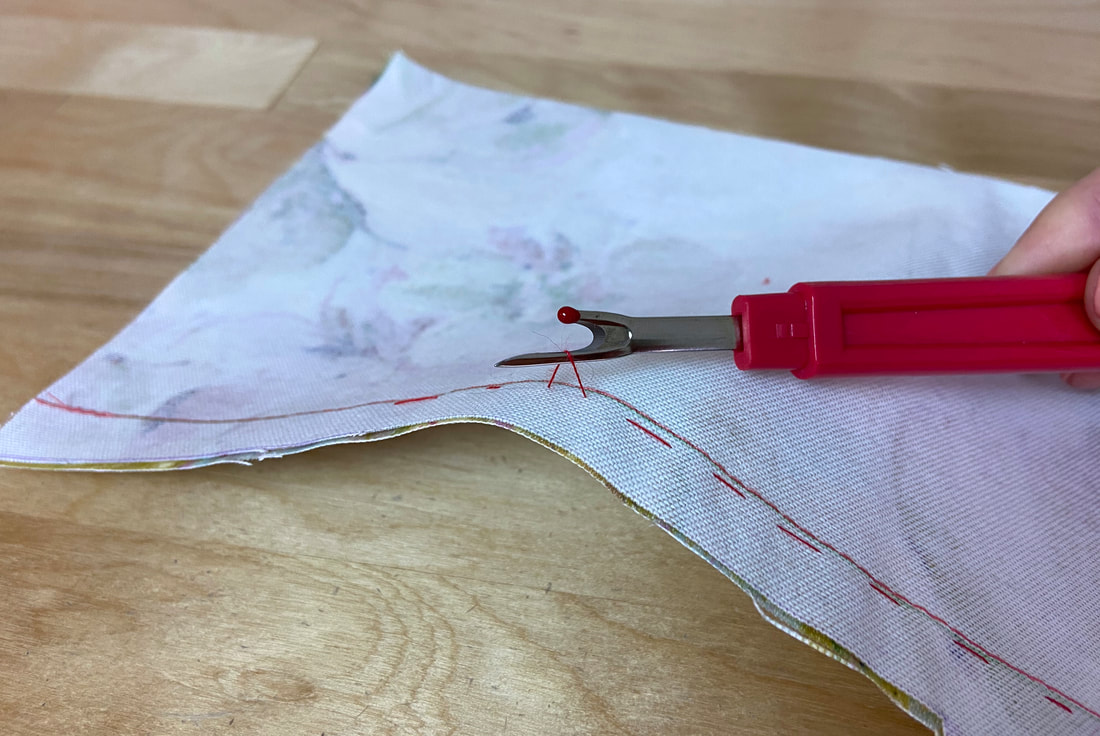

Using a seam ripper, remove all hand basting stitches at this point.

10. First, iron the seam in the direction it was stitched.

Next, open the seam, and with the wrong side facing up, iron the seam allowance open as shown.

Keep in mind that not all seam allowance is ironed open. This should only be done if no other technique is specified.

Depending on the project, seam allowance can be pressed to a single side or enclosed in self-bound finish prior to being ironed.

11. As a last step, press the seam one more time from the face side. Make sure to use a protective cloth for heat sensitive fabrics.

If unsure of your fabric’s heat setting requirements, always test a scrap before proceeding. To be on the safe side, use a cotton cloth as a protective barrier between the fabric surface and iron plate. Use steam as needed.