What Is A Zipper Underlay

A zipper underlay is a single or double layered fabric panel that provides a protective barrier between the skin and the zipper during wear. An underlay is conventionally built as a separate unit featuring enclosed seam allowance edges.

The only zipper application that absolutely requires an underlay is a fly front zipper. This trouser zipper uses something called a fly shield as a protective underlay. Zipper underlays are more commonly used with bottoms like skirts and trousers. In this case, they are stitched to the back of a zipper prior to attaching the waistband.

A zipper underlay is a separate add-on that not only increases comfort but also provides a cleaner look on the inside of the garment. Even if your sewing patterns do not specify the use of an underlay, you can make the decision to add one if you experience skin sensitivity to the zipper teeth or tape.

Keep in mind that an underlay does not work with all zipper applications. Due to its linear, rectangular shape, an underlay may not be suitable for use with side seam invisible zippers, or other similar styles that are built to mold around the organic shape of the body, especially if form fitted. A regular double-layer underlay will add unnecessary bulk to the seam.

If a regular underlay is not suitable, you should consider cutting the underlay at a narrower width and using lightweight fabric.

A single layer style, called a ribbon underlay can also be used. While the ribbon application is not covered in this tutorial, it can be constructed the same way as the conventional underlay shown below.

There are two ways to construct a conventional underlay: Sewing two identical fabric pieces together or folding a single fabric layer in half to self-finish. Both versions enclose the seam allowances for a clean-finished look.

The single fabric layer option is the easiest to complete but limits you to using only a rectangular shaped underlay. If you prefer an underlay that has a curved bottom edge (like a classic fly shield, for example) then two separate fabric layers must be used. Both examples are shown below.

How To Sew A Curved Edge Zipper Underlay

Assuming there are no underlay patterns provided with your pattern set, you can draw and cut the fabric underlay piece(s) directly from the fabric.

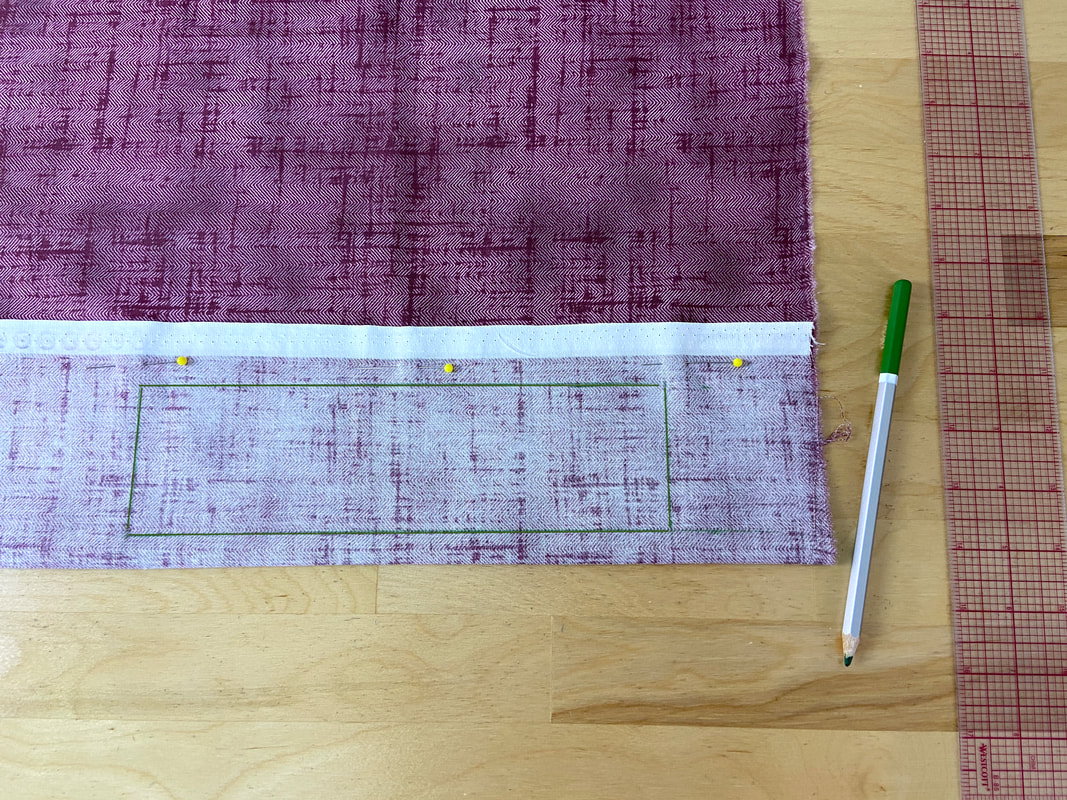

1. Fold the fabric at about 3" from the edge with face sides touching- fabric wrong side should correspond to the outside of the fold. Pin the two fabric layers along the edges to keep them from shifting in the steps to follow.

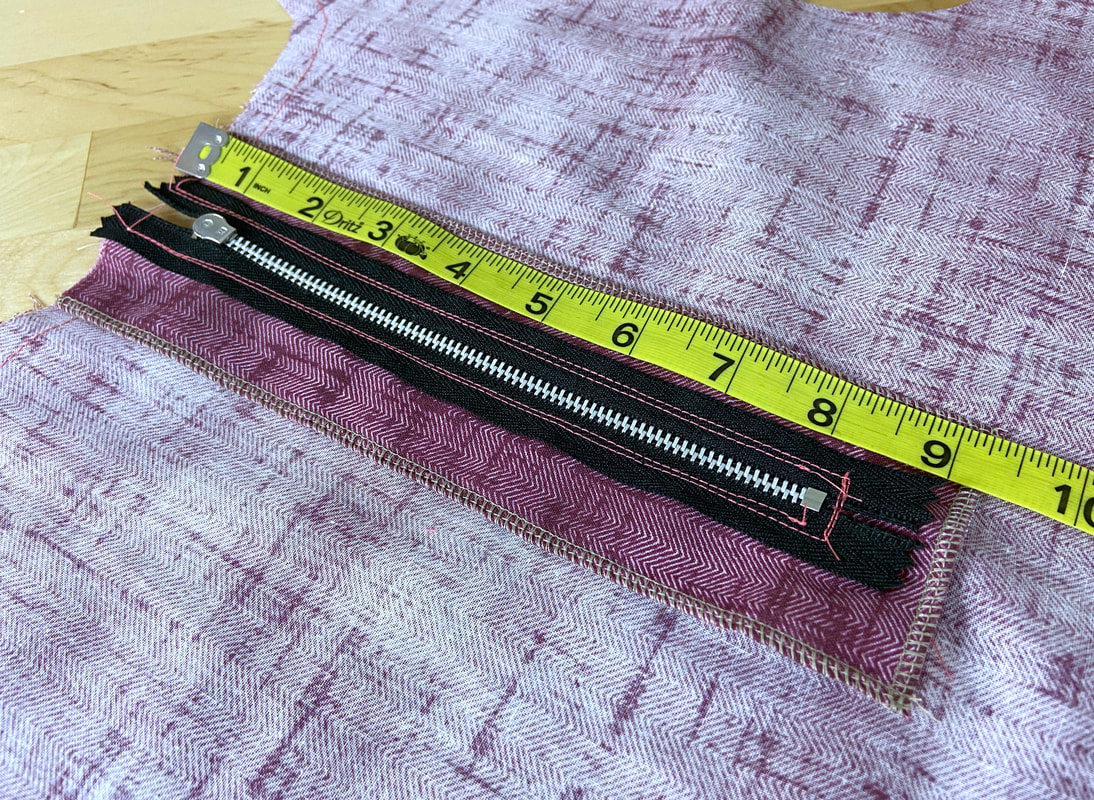

Measure the length of your zipper tape to determine the length of your underlay. Keep in mind, you need the length of the zipper tape and not the zipper teeth.

2. Using a ruler and tailor’s chalk or a quilting pencil, draw a rectangle on the lengthwise grain (parallel to the fabric selvage) measuring 2” wide and the length of the entire zipper tape- 8” in this case.

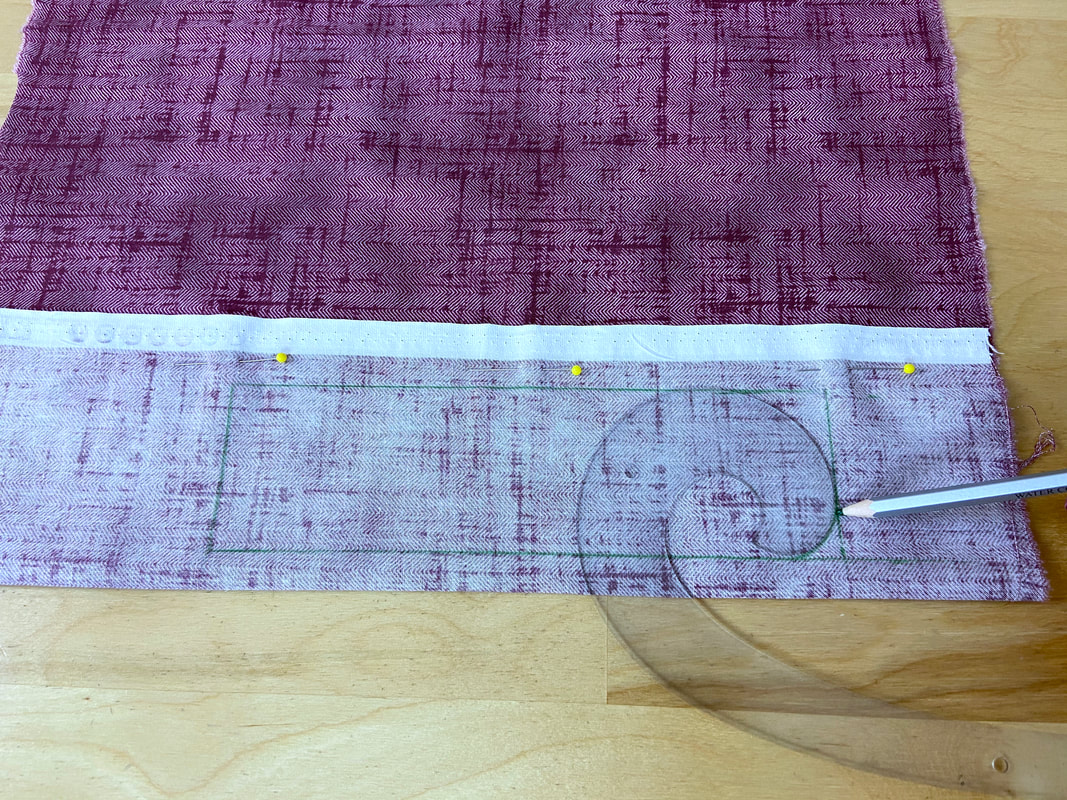

3. Draw a curved line at one of the corners. You can do this by manually smoothing out the rectangular corner or use a French curve for a perfectly curved edge.

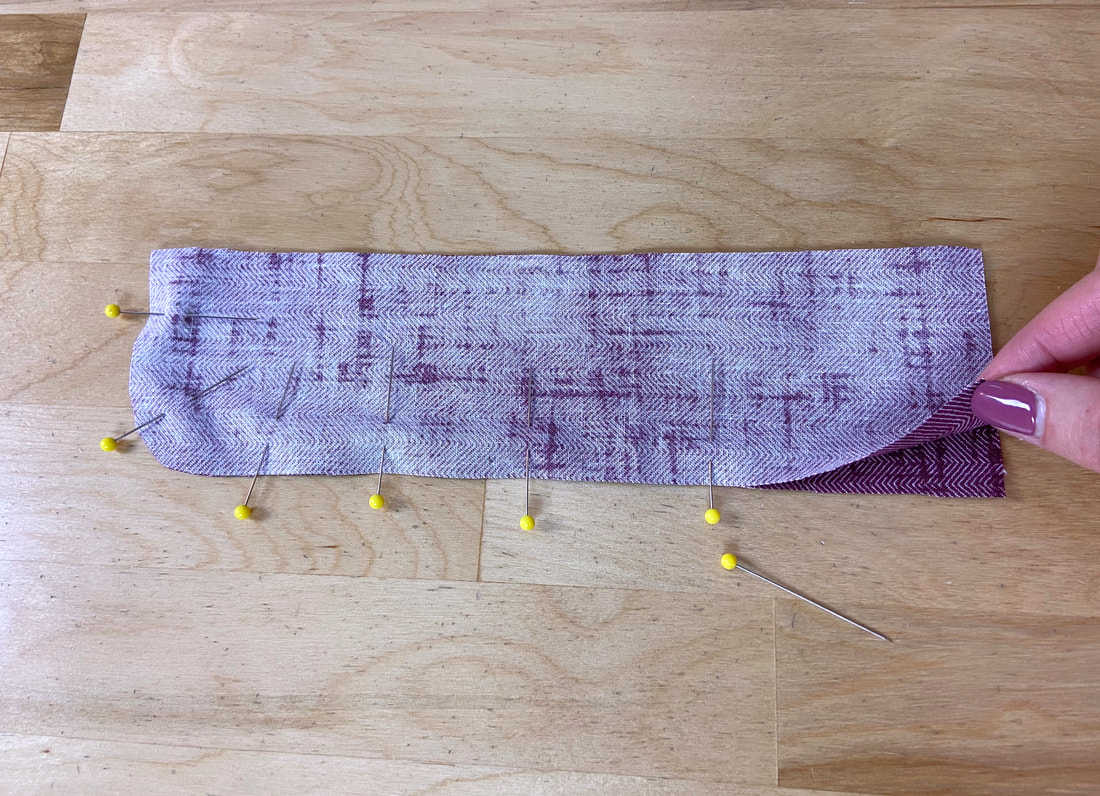

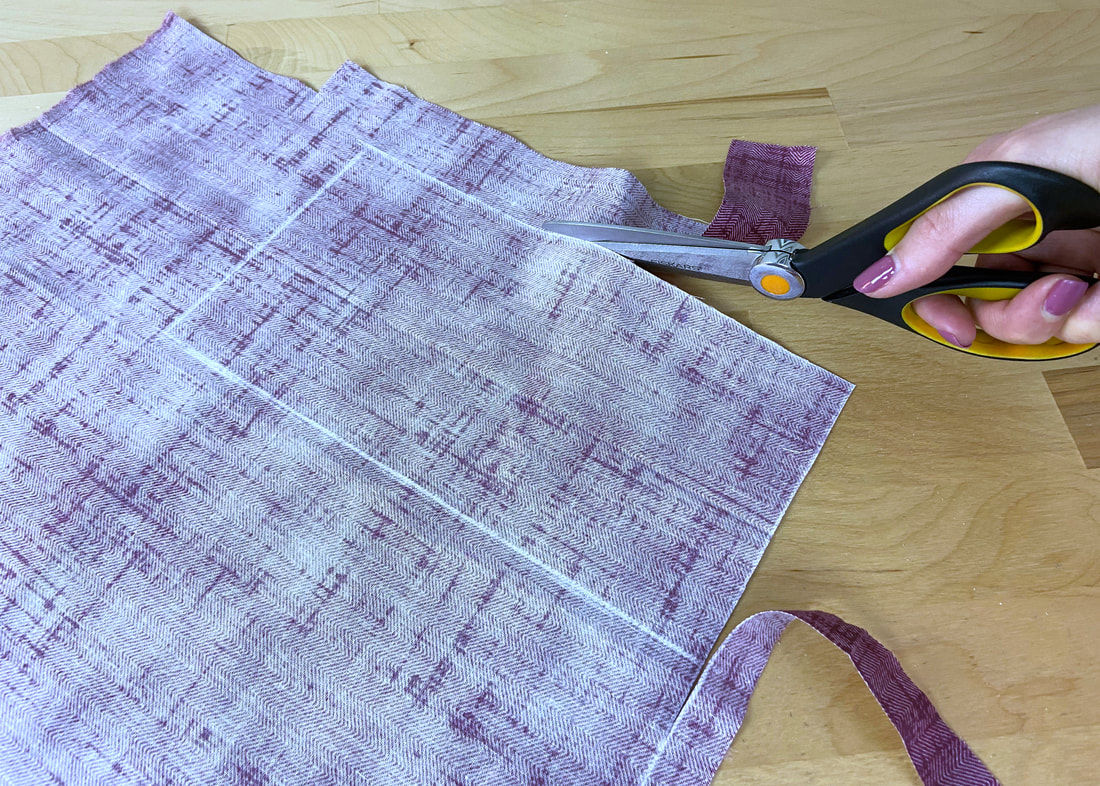

4. Insert a few pins along the rectangle, through both fabric layers as shown. Cut both fabric layers simultaneously along the marked lines, being careful not to shift the two fabric layers away from each other as you cut.

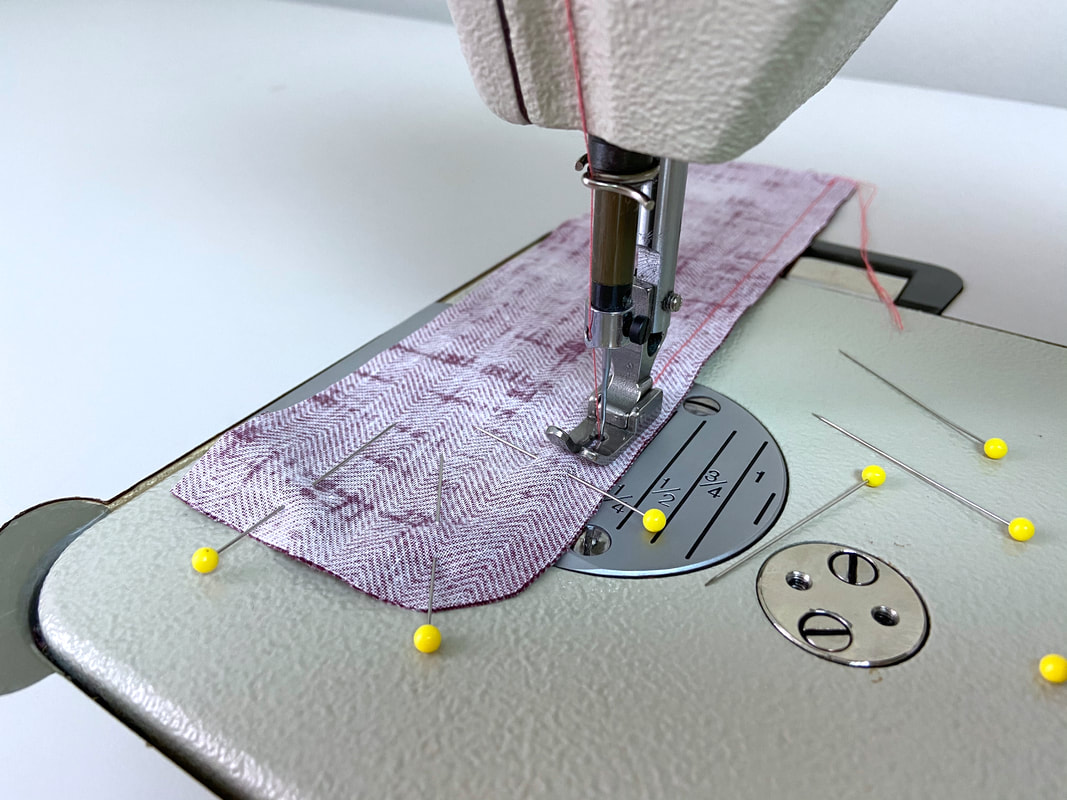

5. Keeping the two fabric layers as they are, pin horizontally through both layers along the outer curved edge as shown. Leave the top and straight edge open.

6. Stitch the curved edge at ¼” seam allowance.

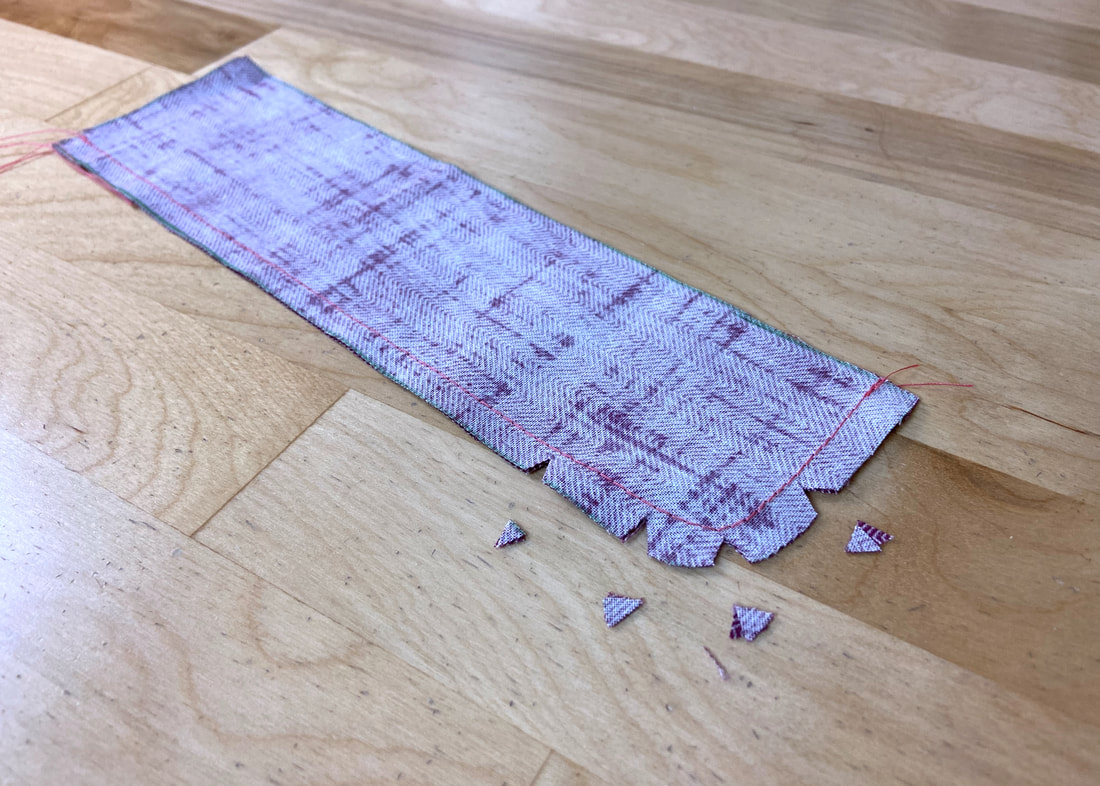

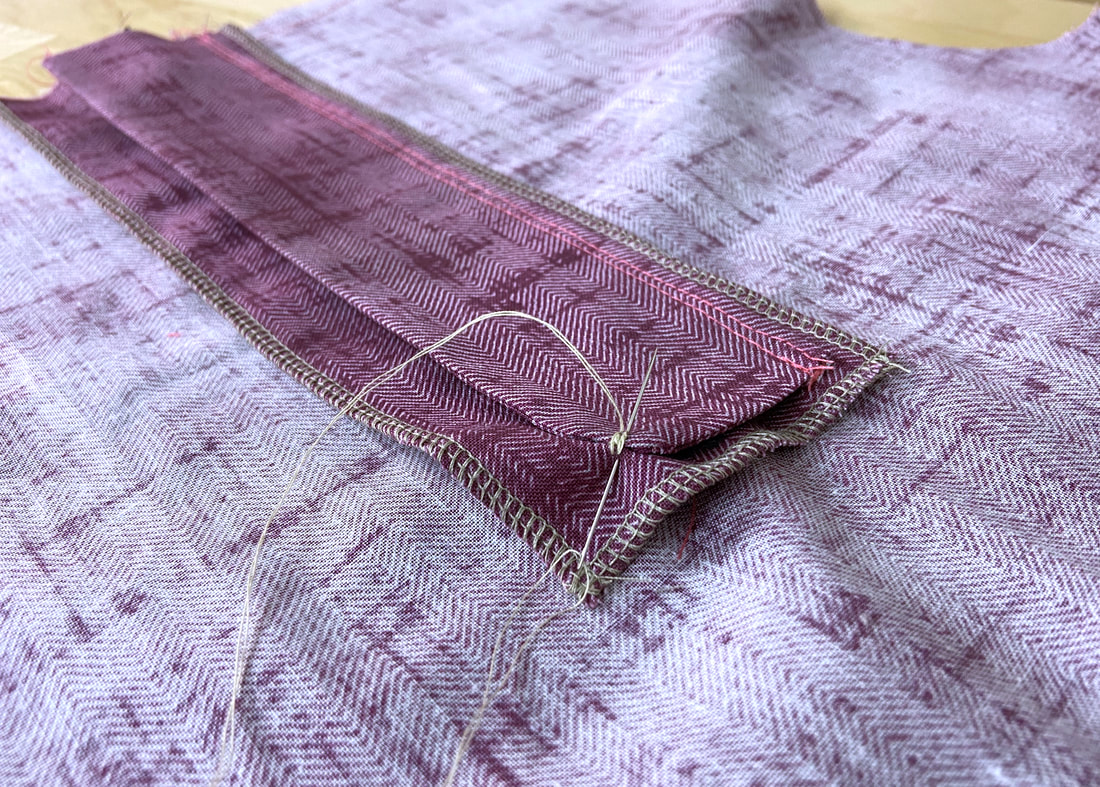

7. Notch the curved area of the seam allowance with wedge-shaped clips as shown. This will minimize bulk and allow the curve to stay smooth and lay flat.

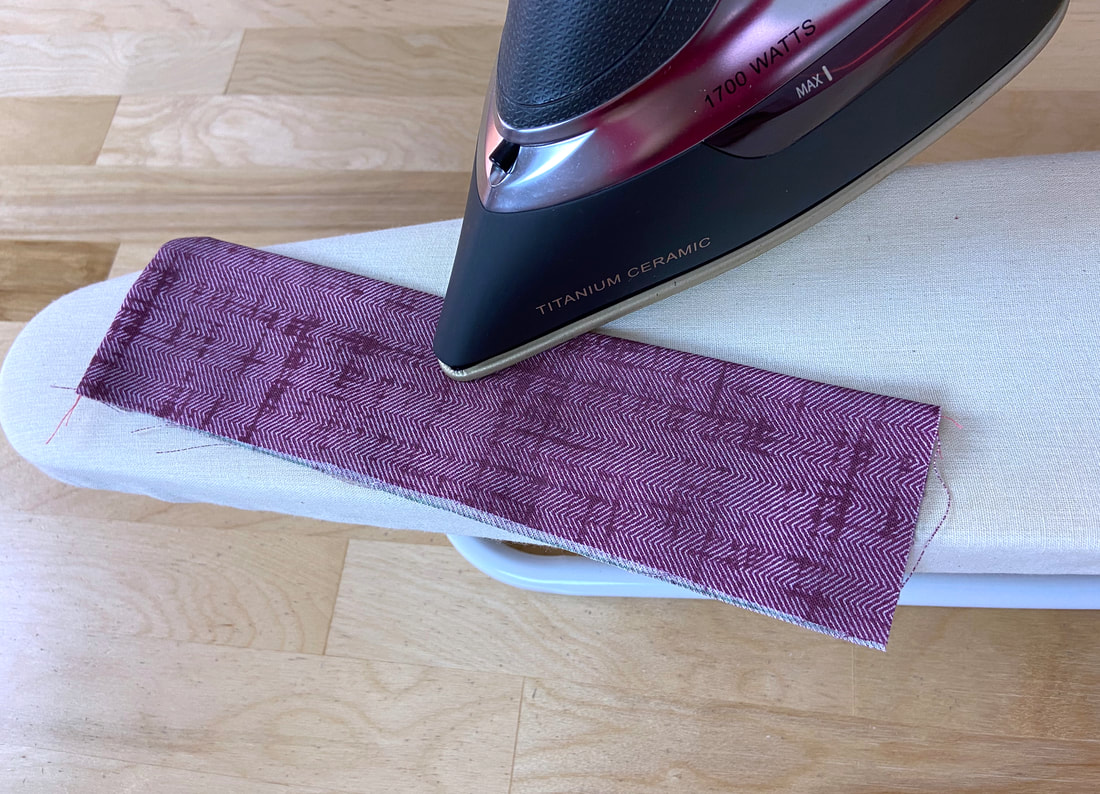

8. Flip the underlay on its right side, bring the curved edge out and iron it flat.

9. Clean finish the straight edge of the underlay. You can use an overedge stitch like serging or zigzag. In this tutorial, one of the layers was trimmed by ¼” and the other was folded over it and topstitched to enclose it.

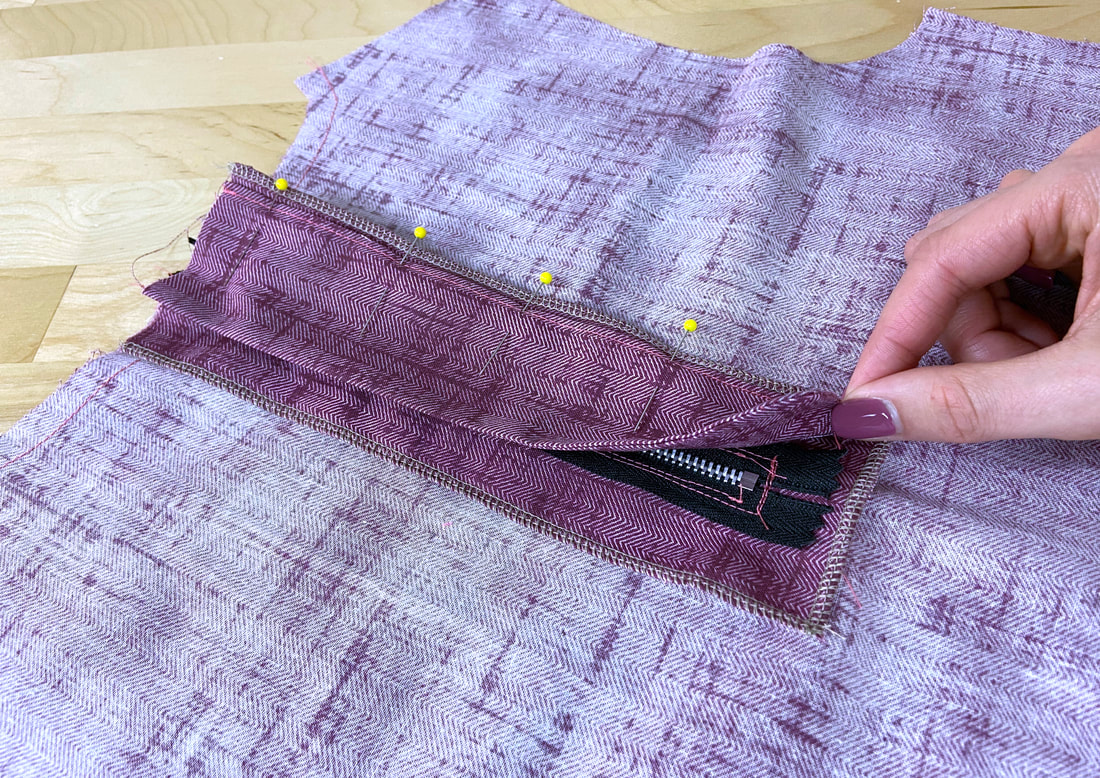

10. Place the underlay to the wrong side of the closed zipper application such that the underlay’s top edge aligns with the garment’s top edge, and its lengthwise straight edge aligns with the zipper’s seam allowance edge as shown. Pin through the underlay’s straight edge and garment seam allowance layer as shown.

11. Stitch the underlay and garment edges together as shown.

12. Tack the bottom of the underlay to the seam allowance layer underneath.

How To Sew A Self-finished (Folded) Zipper Underlay

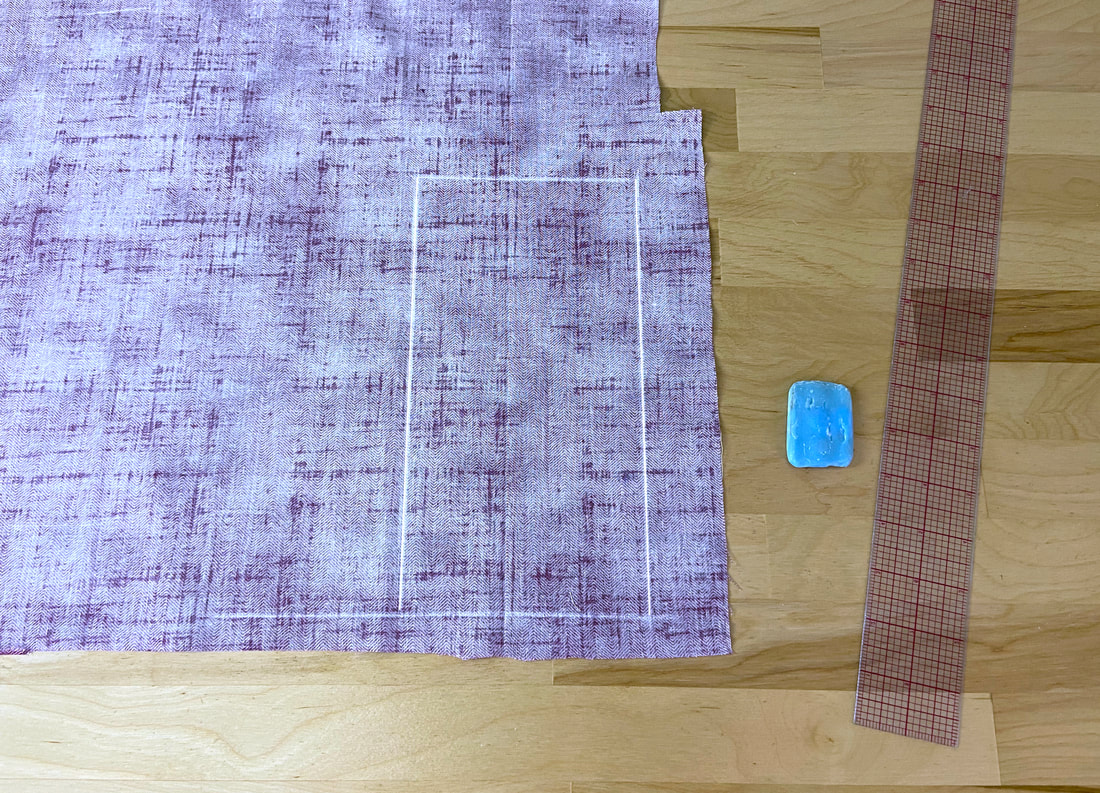

1. To cut a self-finished underlay, lay out the single fabric layer with the wrong side facing up and draw a rectangle that is 5” wide and the length of the zipper tape: in this case, 8”. Use a ruler and tailor’s chalk (or fabric pencil) to draw the rectangle directly on fabric.

2. Carefully cut the rectangle out.

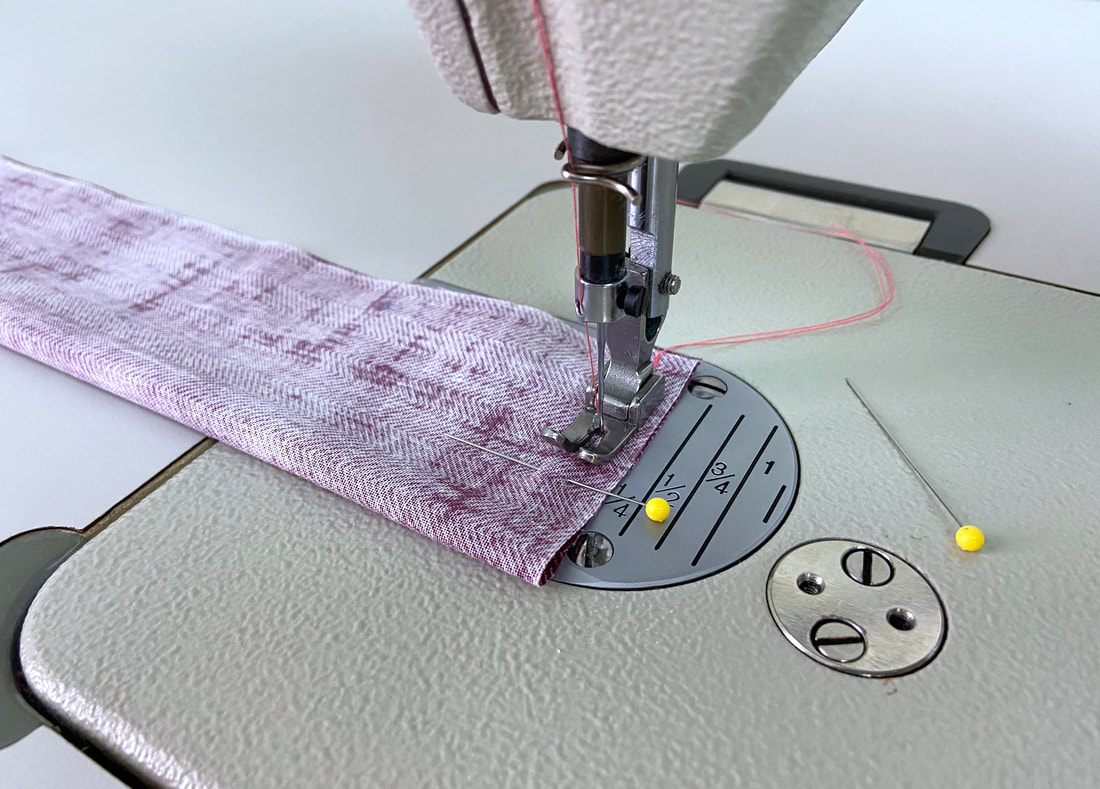

3. Fold the rectangular fabric strip lengthwise down the center such that the face sides are touching. Insert pins horizontally to keep the bottom edges together as shown.

4. Stitch the pinned bottom edges closed at ¼” seam allowance.

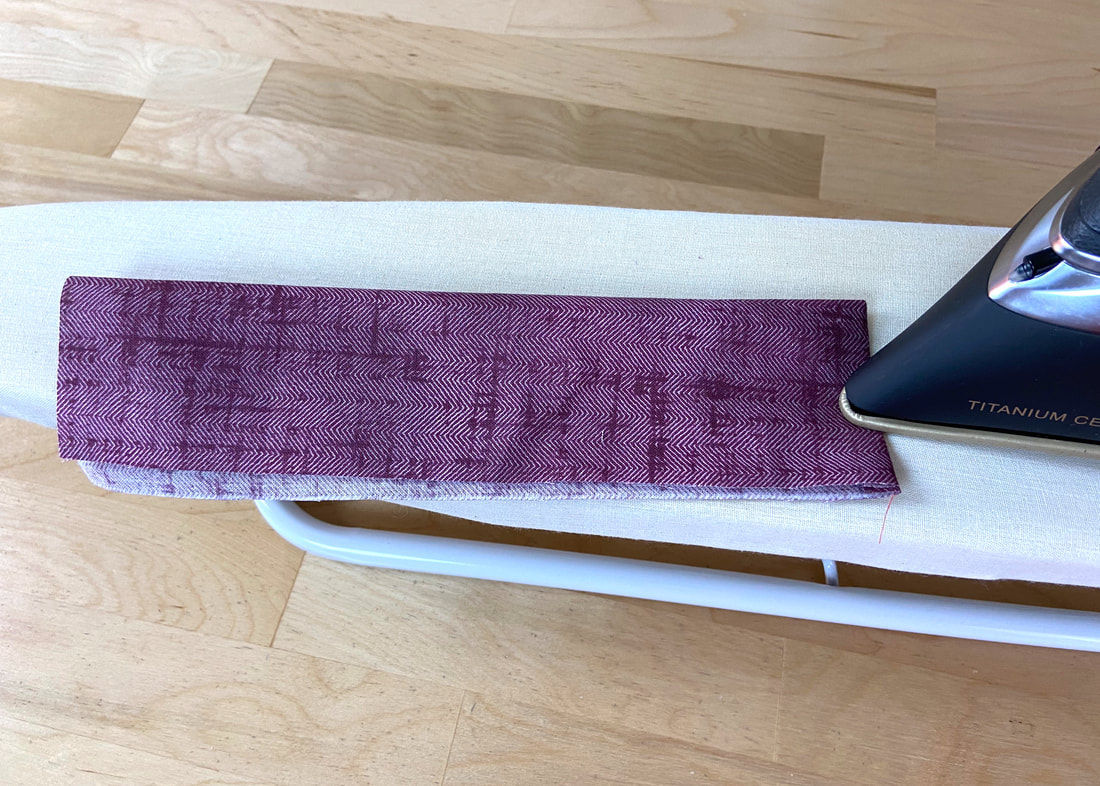

5. Flip the underlay on its right side and iron the finished bottom edge as shown.

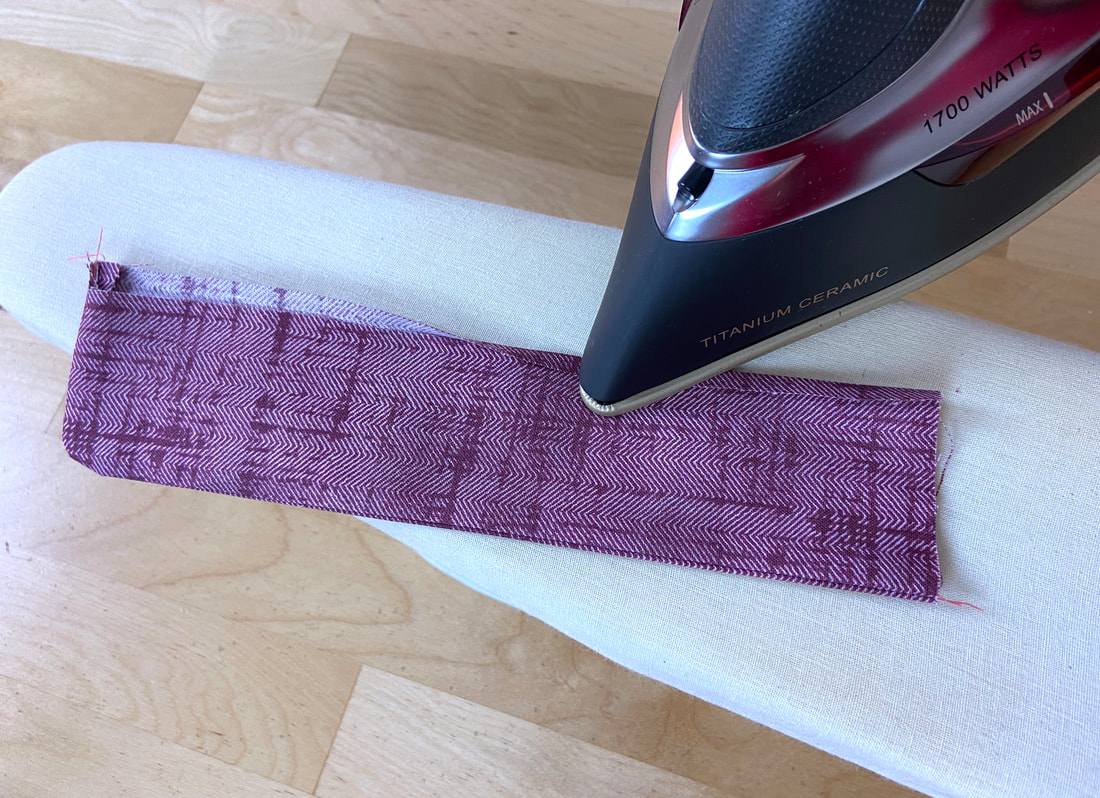

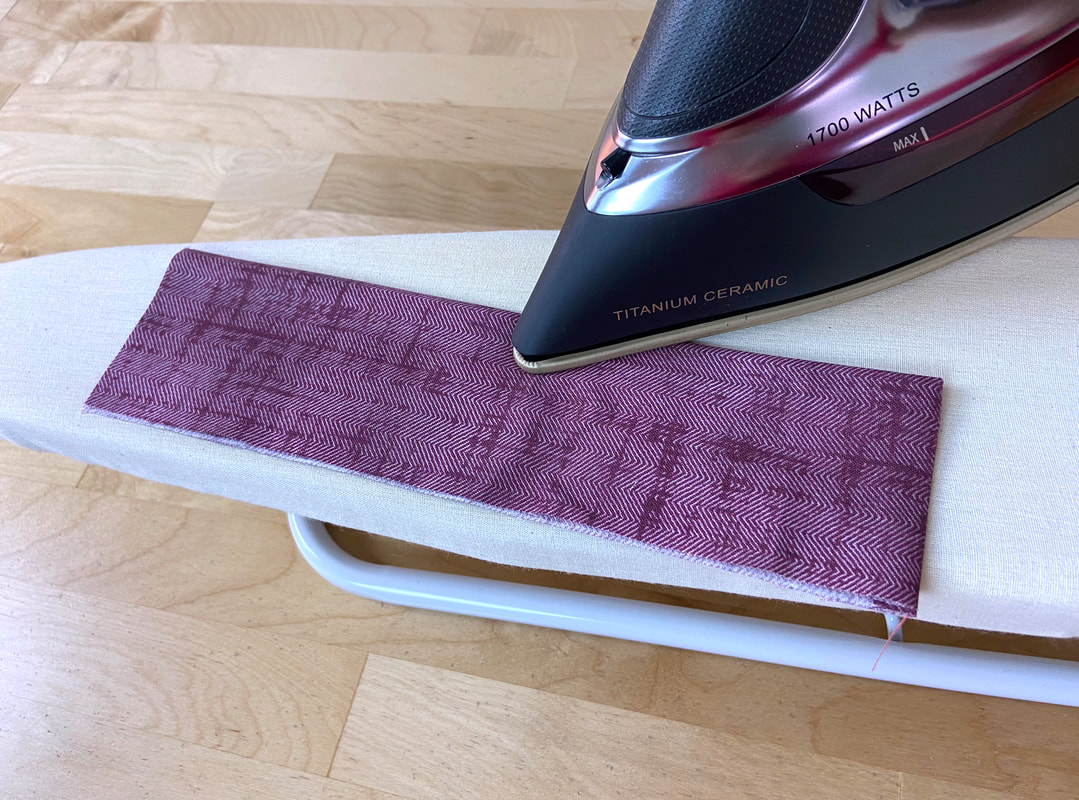

6. Making sure the open lengthwise edges are matching, iron down the center fold to crease.

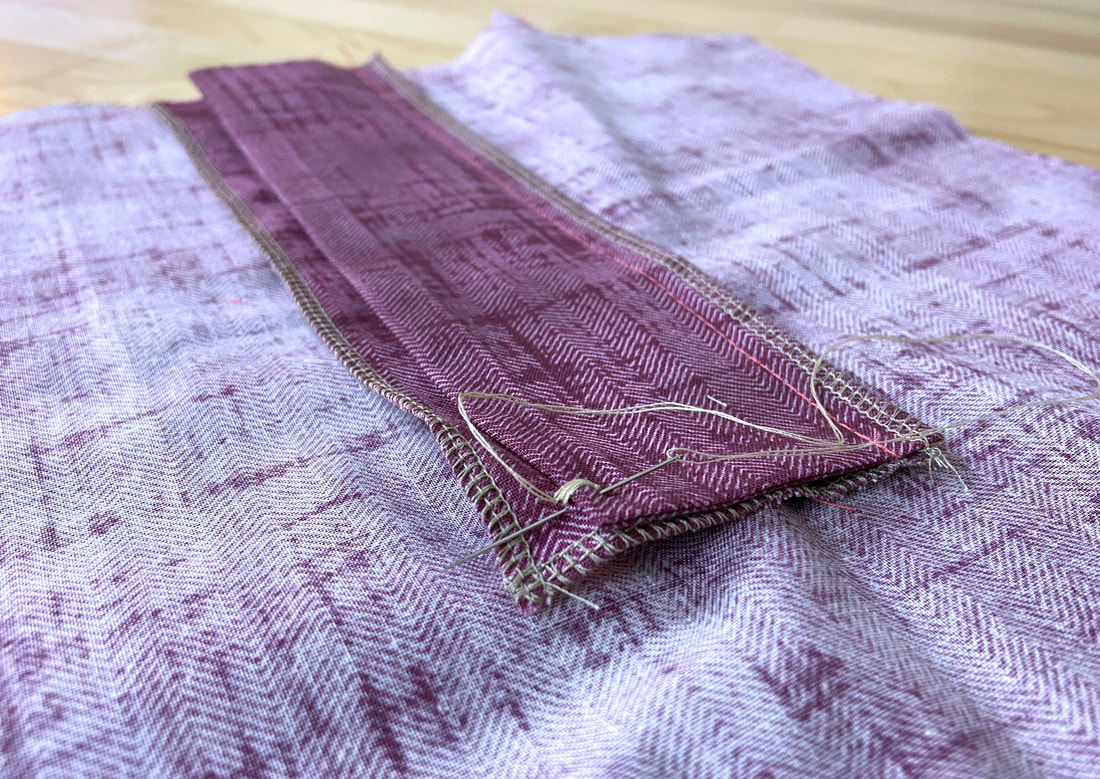

7. Clean finish the open lengthwise edges either using the method shown in the example above or an overedge stitch. In this case, a serging stitch is used to close and simultaneously finish the underlay. You do not need to clean finish the top horizontal edges as these will be sewn into another seam or a waistband.

8. Align the serged edge of the underlay to the garment seam allowance.

9. Last but not least, stitch and hand-tack the underlay’s bottom edge as described above.