Serging and zigzag stitches are some of the most commonly used seam finishes in dressmaking. They are easy to apply, inexpensive, and some of the most effective in preventing fabric edges from fraying.

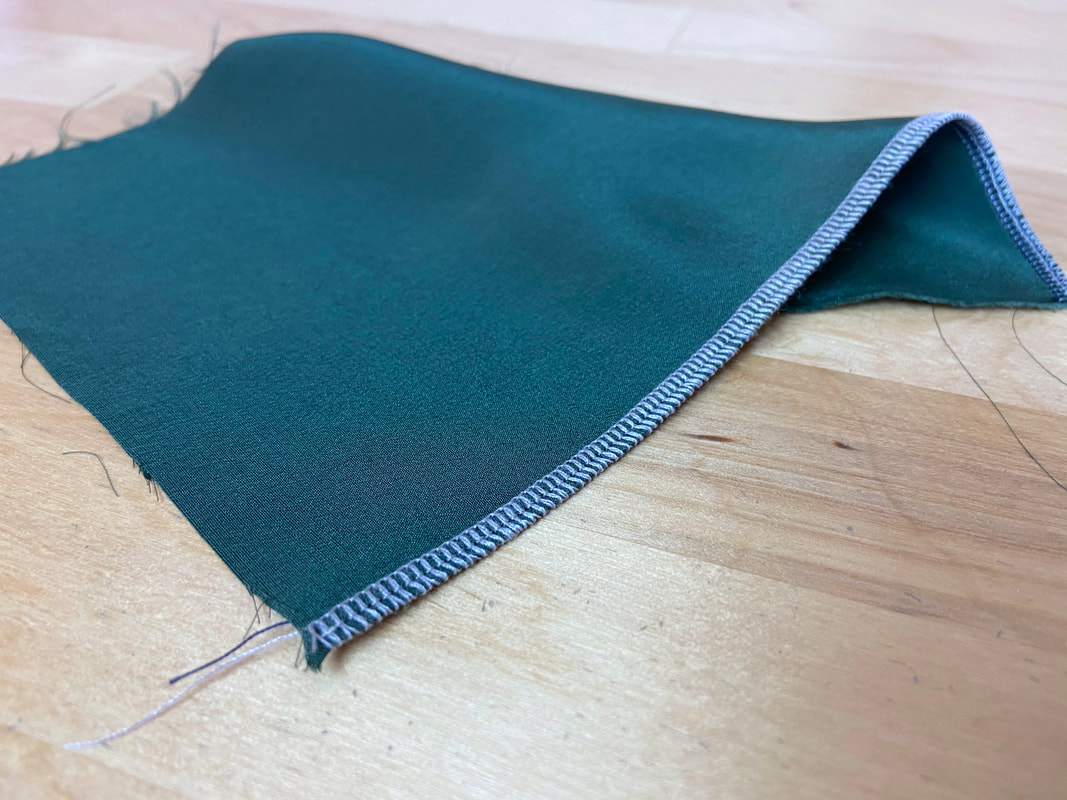

Zigzag and serging are considered overedge stitches and thus fall in the category of overedge seam finishes. Although not always appropriate when the garment's inside is visible on its face side, a fabric edge finished with a serging or zigzag stitch tends to look clean and professional.

An overedge stitch should be applied at the correct density and length for the fabric at hand. Both serging and zigzag stitches should be denser when used with highly fraying, unstable fabrics. On the other hand, a less dense stitch works well with crisp, low-fraying fabrics.

Stitch width is another element to consider and should be chosen according to the fabric type.

A basic rule is that a thick, heavy fabric requires a wider stitch.

On the other hand, a thinner, lighter fabric works better with an overedge stitch that has a shorter width.

What Is A Serging (Overlock) Stitch

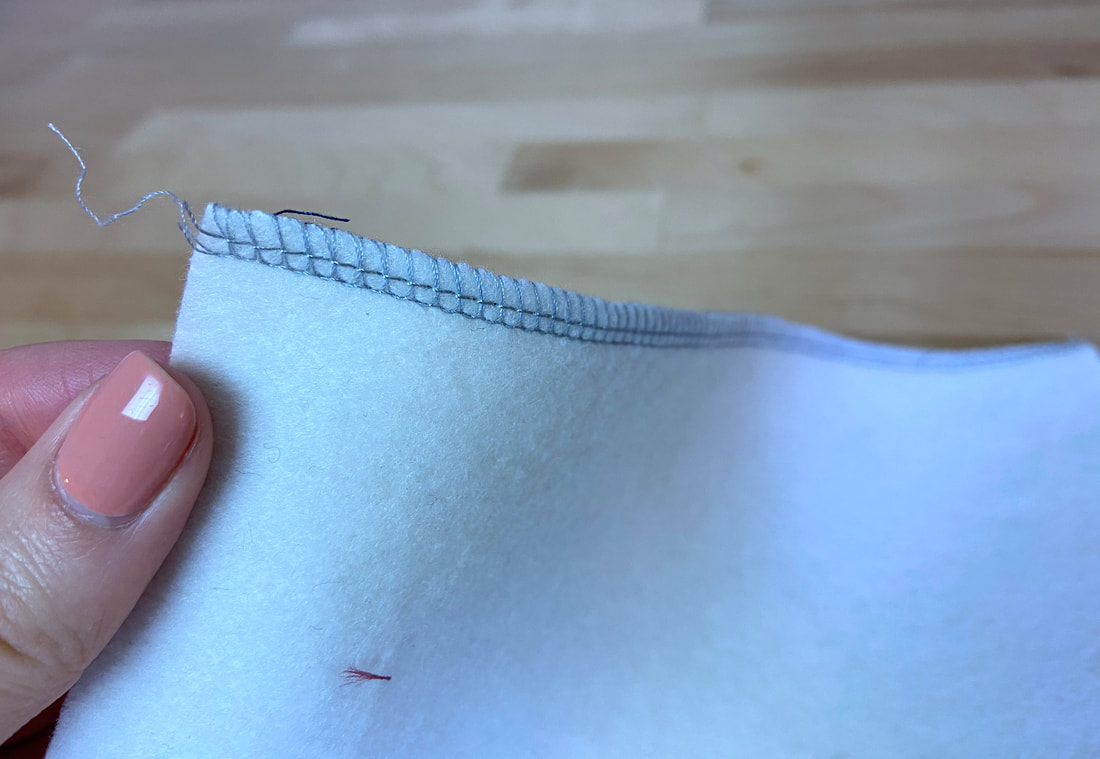

A serging stitch can only be accomplished using an overlock sewing machine, also called a serger. This machine is specifically designed to enclose fabric raw edges with an overedge stitch thus preventing them from unraveling.

Serging is used on both woven and knit fabrics. It provides a professional finish that is commonly used on the industrial level.

As a sewing beginner, you may not be interested in the additional expense of purchasing an overlock machine. However, as you become more advanced, it may be a good idea to invest in one. It provides a better stitching speed, trims the raw edges as you sew, and is suitable with almost all fabric types.

How To Finish Seam Edges With A Serging Stitch

To start with, decide whether the seam allowance layers will be clean finished together or separately.

If clean finished separately, it may be easier to apply the serging prior to sewing the seam.

If the edges are serged together, like in the case of a conventional overedge finish, apply the serging stitch after the seam has been stitched.

1. Place the top edge of the fabric at the front of the presser foot such that the fabric’s lengthwise edge(s) (the edges to be finished) align appropriately with the cutting blade. This alignment is based on how much of the raw edge you need to trim off as you stitch.

2. Begin stitching carefully, guiding the fabric edge under the presser foot. You may need to lift up the presser foot and actually place the fabric under so that it gets some grab as you start stitching.

While applying the serging stitch, keep the fabric edge aligned properly with the machine cutting blade. As opposed to removing a large portion of the seam allowance, trim only enough to achieve a smooth edge. Trimming about 1/8” or less should be sufficient.

3. When arriving at the bottom of the fabric edge, continue stitching to form a 3-inch chain at the end.

4. Cut the thread chain next to the bottom fabric edge, leaving the remainder attached to the machine.

To complete the serged finish, trim the extra chain at the beginning of the stitch as well.

While most fabrics are compatible with serging, always test a scrap piece of fabric before proceeding.

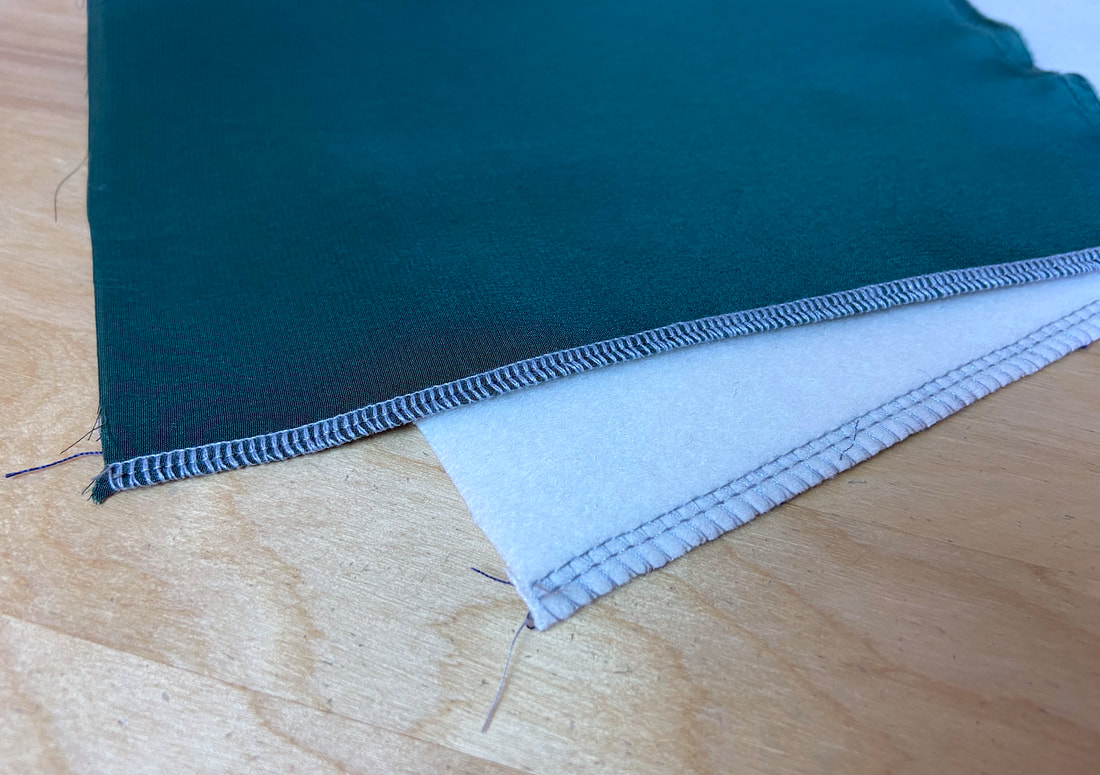

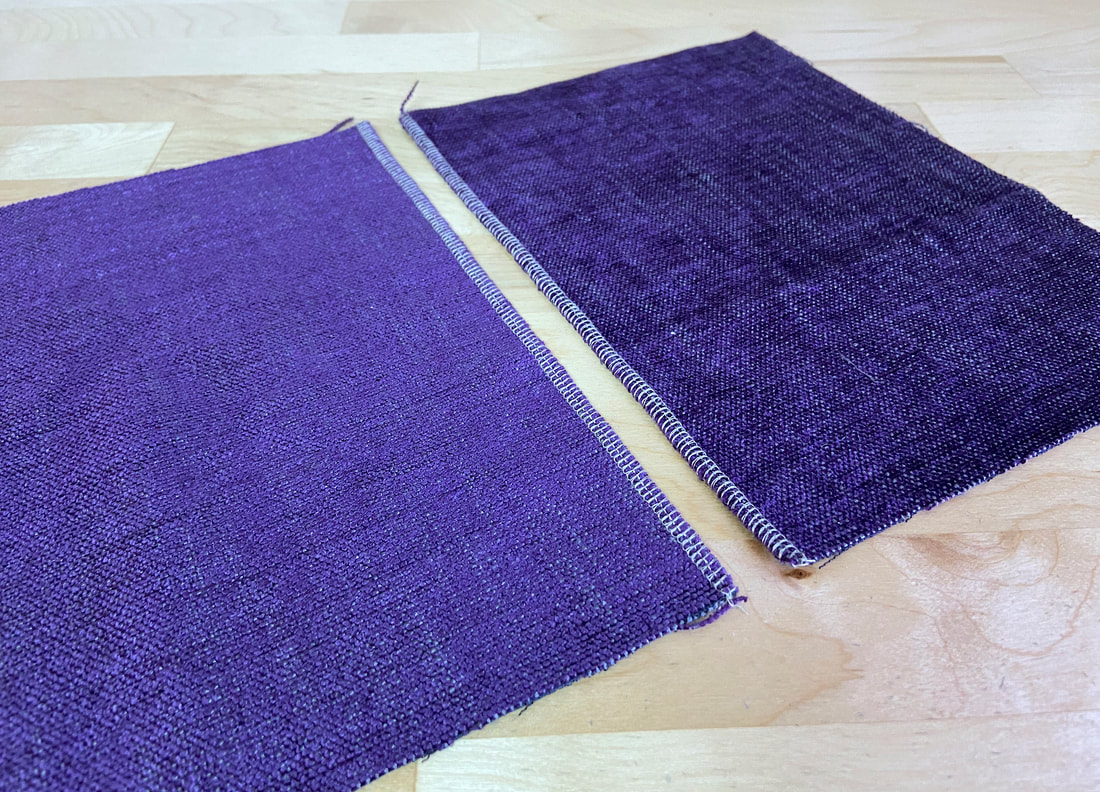

5. To complete the seam, pin and stitch the fabric layers at the designated seam allowance. As a final step, iron the seam allowance open as shown.

What Is A Zigzag Stitch?

A zigzag stitch is a chevron shaped overedge stitch available on almost all home sewing machines. It is often used to sew highly stretch knits as it provides lengthwise flexibility.

Similar to a serging stitch, a zigzag stitch can be adjusted based on the width and density needed for the fabric at hand. It is perhaps the best alternative for serging, commonly used by beginner-to-intermediate dressmakers to clean finish fabric raw edges at home.

While not as fast or as efficient as serging, zigzag stitches work in a similar fashion to enclose fabric raw edges and prevent them from unraveling. Since regular sewing machines do not have trimming blades, the stitch is applied at a short distance from the seam allowance raw edge, after which the fabric edge is trimmed along the zigzag to complete the finish.

Finishing Seam Edges With A Zigzag Stitch

Similar serging process described above, decide whether the zigzag should be applied prior to sewing the seam or after. If the edges will be finished separately, you should consider applying the zigzag stitch along each edge first, prior to sewing the seam and trimming the remaining excess.

On the other hand, if the seam allowance edges will be finished together, it is easier to sew the seam first, apply the zigzag stitch through both edges simultaneously, and finally trim the unnecessary excess.

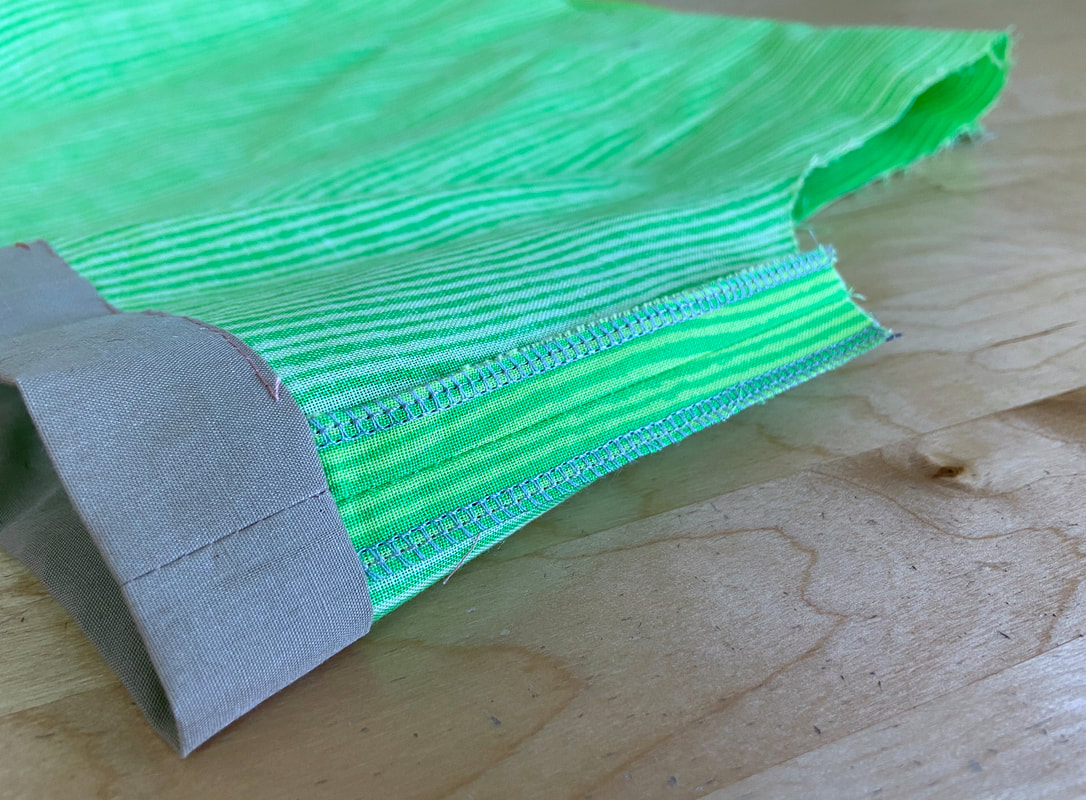

In the example below, the seam allowance edges are finished separately:

1. Apply a zigzag stitch at about 1/4" - 1/8” away from each seam allowance raw edge as shown.

2. Align the zigzagged seam edges with the face sides touching, following all appropriate marks and sewing notches. Pin the seam perpendicular to the edge and stitch it at the designated seam allowance.

3. Trim the raw edge excess close to the zigzag application being very careful not to accidentally slit through the actual stitching.

Note: Applying the zigzag stitch directly along the fabric raw edge may cause some tension resulting a less flat finish.

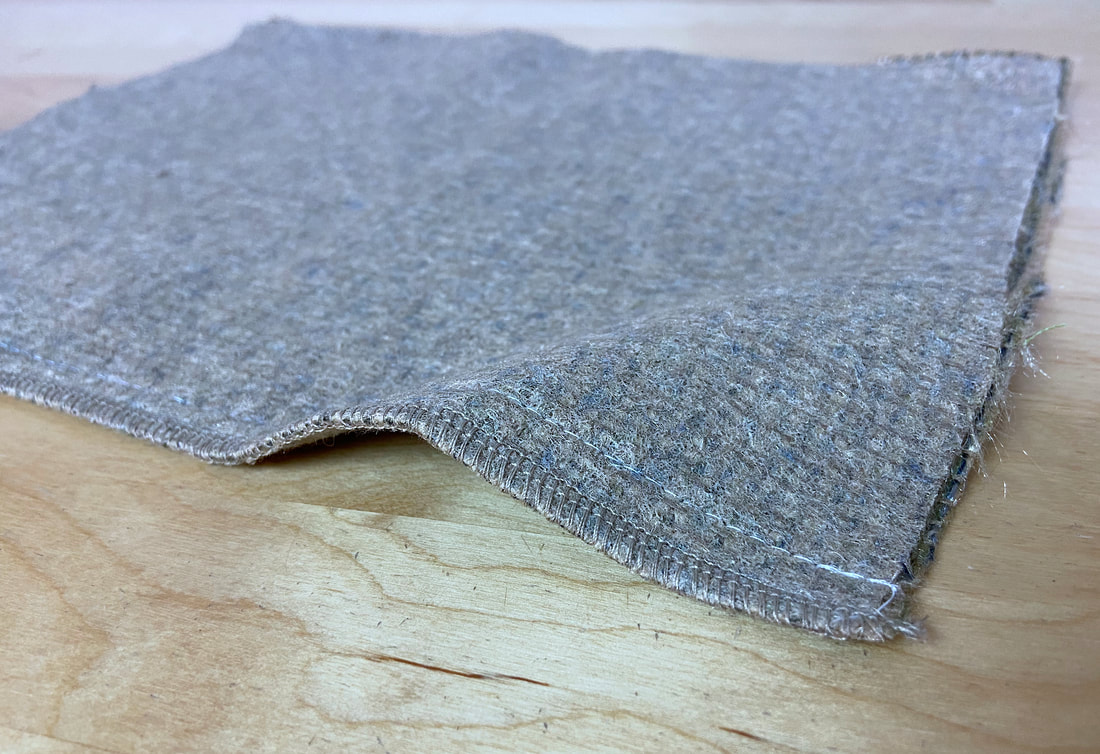

4. Iron the seam allowance open or as directed in your sewing instructions/specifications.

If your seam allowance is wide enough, you can zigzag the individual edges after the seam has been stitched, but prior to ironing the seam allowance. However, as you stitch along each fabric edge, be very careful not to catch other garment layers underneath.