Regardless of where it is used on the garment, the purpose of interfacing is to provide structure and stability.

Along a garment’s hem, interfacing allows the hemline to lay flatter, sharper and stand away from the garment in a structured drape.

Interfaced hems are mostly used with tailored items that are constructed of medium-to-heavy weight fabrics. Items like coats, blazers, tailored skirts and dresses have more structure if interfacing is used at the hem.

When interfacing a hem, two factors are important to consider: the type of interfacing used and how it is positioned in relation to the garment’s hem allowance/hemline.

If you are familiar with the basics of interfacing, you most likely know the difference between the fusible and sew-on styles.

Fusible interfacing has an adhesive side that is bonded to the fabric surface using heat.

Sew-on interfacing is either stitched into the seam or catchstitched to the fabric surface to keep in the desired position.

Fusible interfacing is readily-available and much easier to apply along the garment’s hem allowance. Since it is heat bonded, it does not require any blind stitching the way a sew-on interfacing does.

A sew-on interfacing has to be catchstitched/slipstitched along the garment’s hem since there are no seams can house its lengthwise edges.

In terms of how the interfacing is positioned in relation to the hemline, this depends on the hem finish and whether the garment is lined or unlined.

Lined garments can hide interfacing that is positioned higher than the folded hem allowance. This is often the case with tailored lined jackets, blazers, and suits.

If the garment is unlined, the interfacing will have to be positioned such that it is hidden within the turned-up hem allowance.

Conventionally, interfacing is used on fully lined garments or those that are finished with a wide hem allowance or a wide hem facing.

In the two examples below, you will learn how to add interfacing to the hem of a fully lined garment, and to the folded hem of an unlined garment. The interfacing in the latter example is fully hidden within the folded hem.

Both fusible and sew-on interfacings are used.

Interfacing The Hem Of A Lined Garment

In a lined garment, the interfacing is placed higher and hidden underneath the lining layer.

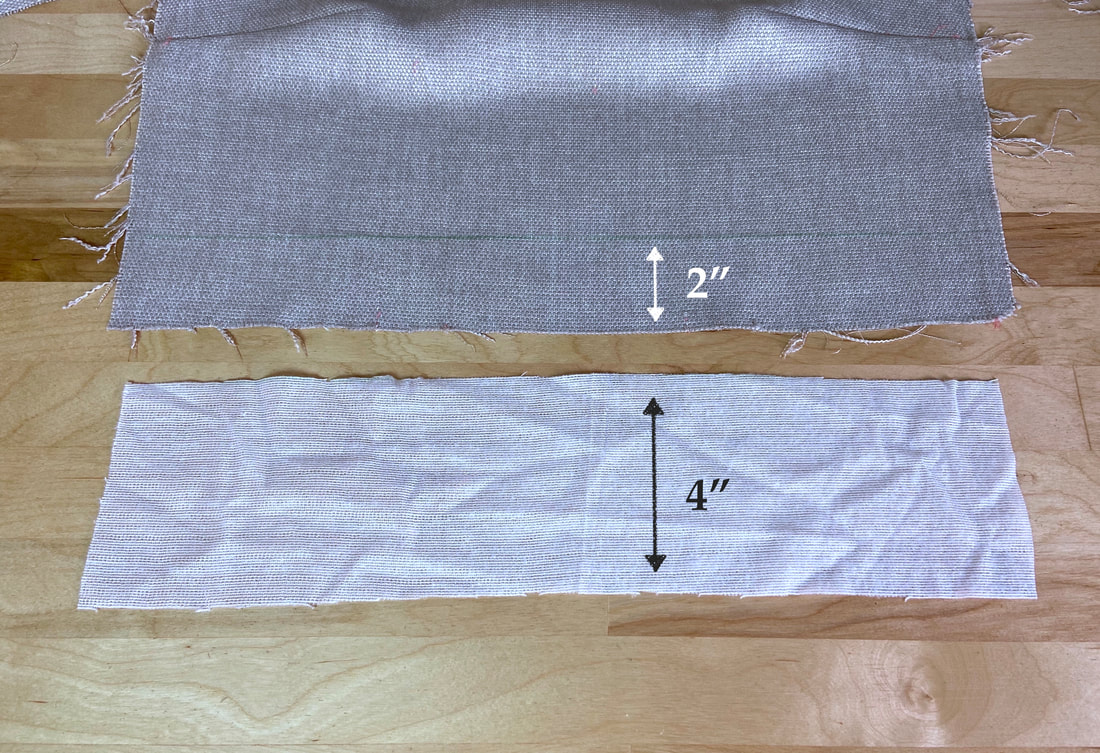

Remember, a hem interfacing strip is cut 2” wider than the hem allowance it backs. In this case, the hem allowance is 2” thus the interfacing strip is 4” wide.

Fusible interfacing is used in this example.

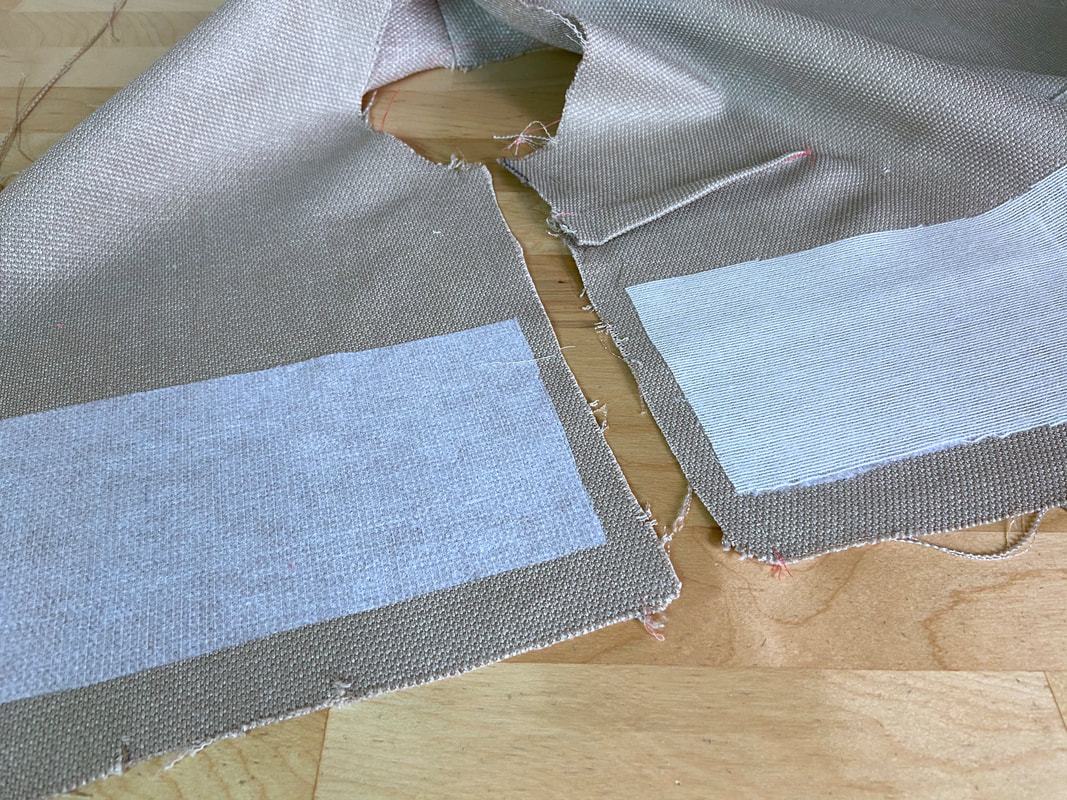

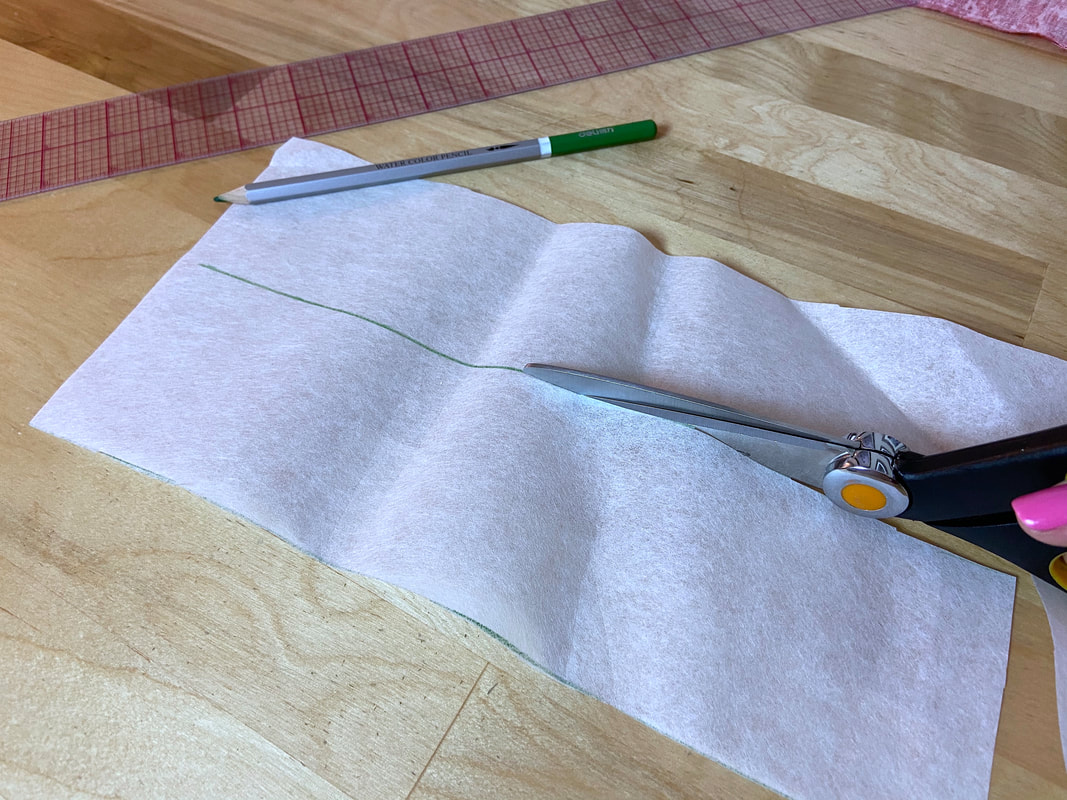

1. Cut the 4” interfacing strip(s) to cover the entire hem edge.

2. Place the interfacing strip with the adhesive side touching the wrong side of the fabric, such that its bottom edge is aligned about 1” below the hemline and thus extending 3” above it. If you do not know exactly where your hemline is, simply measure the hem allowance width up from the garment’s bottom cut edge, and mark this line with tailor’s chalk or a fabric pencil.

Note: If using fusible interfacing, don’t mark the hemline with hand basting or it will be very difficult to remove.

3. Using a protective cotton cloth, iron to fuse the interfacing in this position.

The interfacing should be ironed on prior to the seams being sewn.

3. After the interfacing is attached, sew and finish the garment seams as instructed.

4. Only after the seams are finished, fold the hem allowance up such that the fold line corresponds to the finished hemline, and press it in this position.

5. Catchstitch/slipstitch the hem allowance cut edge to the wrong side of the garment and complete the lining.

After the interfacing is attached, you should notice a big difference in the hem’s structure and stability.

Interfacing A Folded-Up Hemline: Unlined Garment Example

When interfacing the folded hem on an unlined garment, the interfacing should be fully enclosed within the hem allowance and not show anywhere on the outside of the finished hem.

In this instance, it helps to work with a wider hem allowance. Conveniently, interfacing is used with medium-to-heavy fabrics which naturally require wider hem allowance.

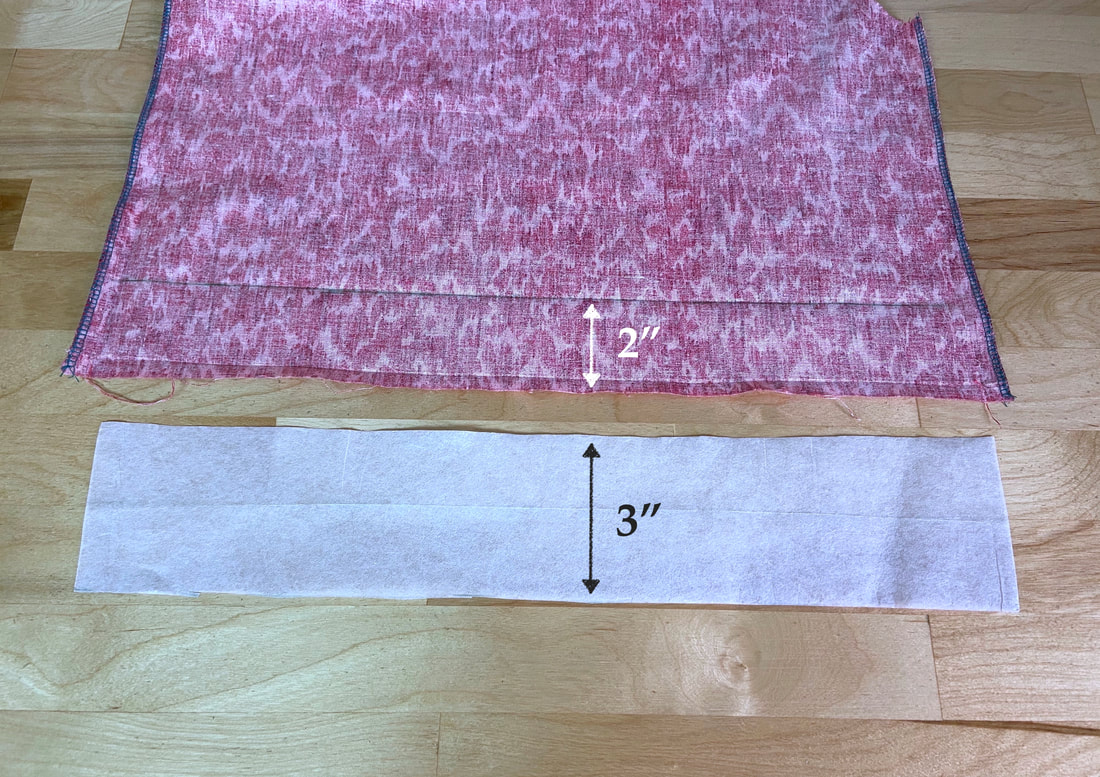

With unlined garments, the interfacing strip should only be 1” wider than the hem allowance width. In this case, the hem allowance width is 2” thus the interfacing strip will be 3” wide.

For practice, a non-fusible sew-on interfacing is used in this scenario.

1. Cut the interfacing strip(s) to cover the entire length of the hemline.

2. If not already marked, determine the garment’s hemline and mark it on the wrong side of the garment with either a hand basting stitch or tailors chalk.

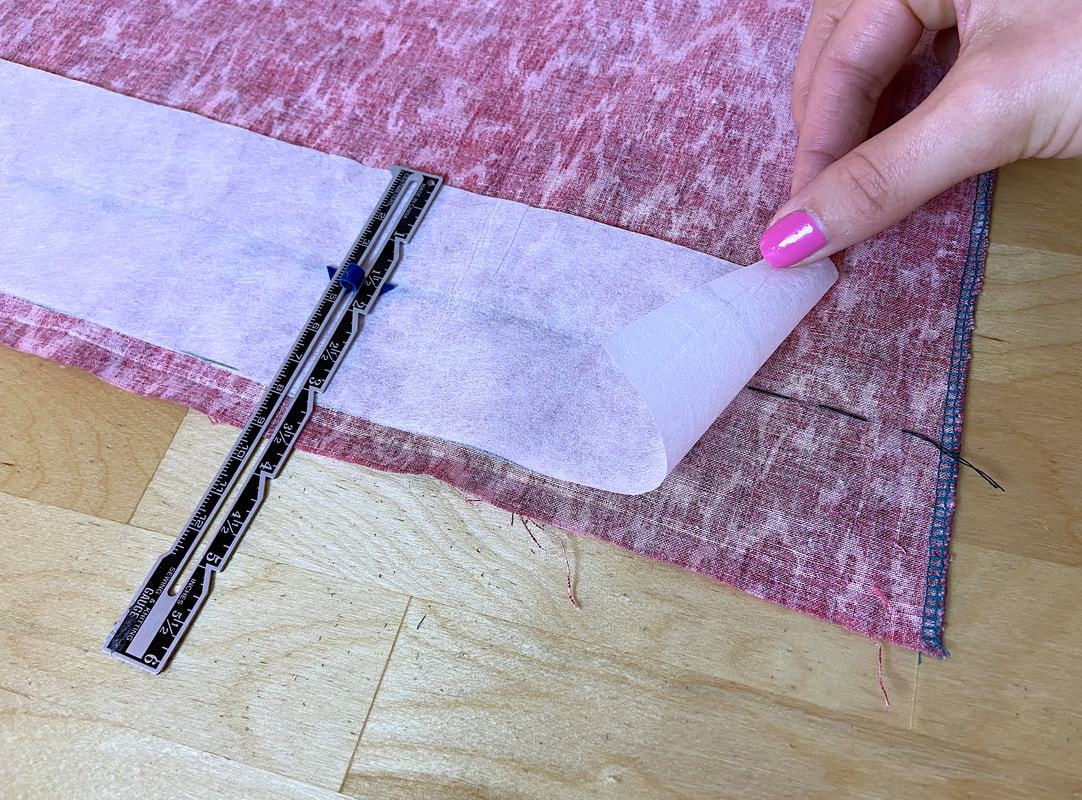

3. Align the interfacing strips to the wrong side of the fabric pieces such that the bottom edge of the interfacing extends 1 ½ inches past the marked hemline. Insert pins to secure the sew-on interfacing strip in this position.

4. To attach the interfacing, blind stitch its bottom and top edges to the wrong side of the garment surface as shown.

5. Sew the garment's seams intersecting the hem.

6. Next, carefully fold and iron the hem allowance up such that the fold corresponds to the finished hemline. The interfacing should be fully enclosed within the folded hem.

At this point, finish the folded hem allowance as specified by your project. Last but not least, remove the hand basting using a seam ripper.