If you’ve ever worked with sheer fabrics, you know they can be quite tricky to cut and handle in the sewing process. When it comes to finishing a sheer garment's hem, only a few techniques will work without affecting drape and adding unnecessary bulk.

Most sheer fabrics can be finished with a single or double-folded hem.

No binding and hemming tapes should be used as these can weigh down the fabric and add unnecessary bulk. A regular topstitched or hand-sewn folded hem works great with crisp, structured sheer fabrics (like organza and voile) that have a straight or slightly curved hem.

However, when working with draped, flimsy sheers like chiffon (especially silk chiffon), handling each fold individually during the hem finishing process is not only time consuming, it is also very difficult to do. In this case, a rolled hem finish is used to double fold the fabric edge at a very narrow width in a single step, without the need for pre-folding.

A rolled hem, also called a baby hem, has a hem allowance of 1/4” or 3/8”. In the finished application, the hem’s raw edge is folded up once at 1/8” then a second time at 1/8”. The second fold encloses the fabric’s raw edge. Instead of manually folding these narrow edges, the entire hem is simply rolled in this double-fold position either by hand or by machine using a hemmer foot.

The hand-applied option provides a higher quality finish with no visible stitching on the face of the garment. A type of blind stitching is used in this case.

A machine application is much faster to complete but requires a special hemmer foot that automatically rolls the fabric edge in a double fold, each fold measuring 1/8” in width. This special hemmer foot is not always provided with your sewing machine kit so you may have to purchase it separately. Make sure you choose one that is compatible with your sewing machine model.

As you might have guessed, a machine stitched rolled hem leaves a row of topstitching along the finished hem which as opposed to the hand-applied application, is visible on the face of the garment.

Sewing A Rolled Hem By Hand

1. To start with, make sure all garment seams have been sewn and clean finished.

If the hem allowance is not already 1/4” in width, you will have to trim it down to 1/4”, but first, a stabilizing stitch is added to facilitate the sewing process later on.

In this tutorial, the total hem allowance is 1”. Thus, an excess of about ¾” will be trimmed off from the original hem allowance edge.

2. Start by marking the original hemline: Using a gage pointer or ruler, measure and mark the 1” hemline with tailor’s chalk or a fabric pencil first.

3. Add a straight stitch a little less than 1/4” from the marked hemline as shown. This stitch will provide a folding guideline as well as keep the fabric edge more stable during the folding process to follow.

Note: Use your gage pointer to measure down and mark a general starting point, then use your machine’s seam allowance guides to apply the straight stitch evenly across the hem allowance.

4. Trim the excess hem allowance about 1/8" below the straight stitch as shown.

5. Fold over the stitched edge toward the wrong side of the fabric at halfway through the hem allowance (1/8”) and a little beyond the stitch applied in Step 3 above. Iron this folded edge to crease.

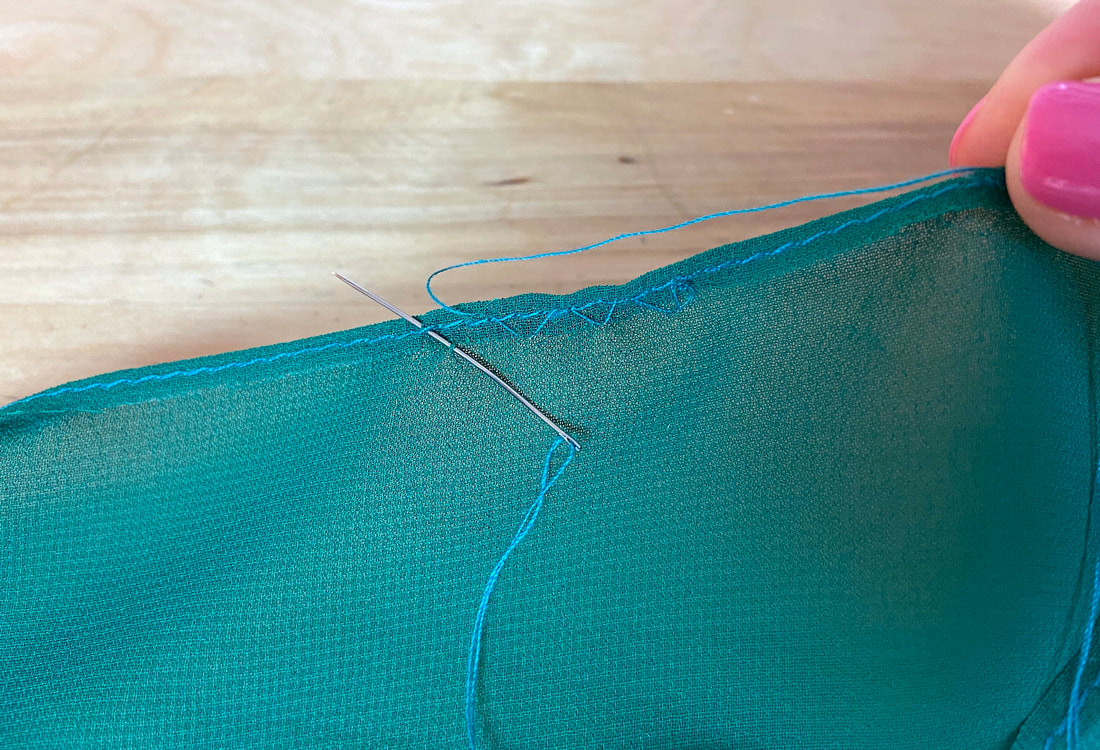

6. Using a hand sewing needle and matching thread, catch a stitch through the folded layers and another through a couple of threads on the garment’s wrong side at about 1/8” down from the folded edge.

Continue stitching, alternating between the fold and the garment surface as described above. Apply the stitching loosely for a distance of 1-2”, then pull the thread in: this will cause the fold to naturally roll towards the wrong side of the garment and automatically enclose the hem’s raw edge.

7. As a final step, it is important to iron the finished rolled hem for a smooth, flat finish.

Sewing A Rolled Hem By Machine

It is very difficult to sew a rolled hem by machine without a specialized hemmer foot (shown below).

1. If not already ¼”, trim the hem allowance down to ¼”. When machine stitching a rolled hem, there is no need to apply the stabilizing stitch described above.

Before rolling the fabric edge around the hemmer foot guides, give the rolled hem a little folding start.

2. Starting at a point along the hem, fold the fabric raw edge towards the wrong side of the garment at 1/8”, crease the fold with your finger and iron as shown.

Fold again at 1/8” to enclose the fabric raw edge, crease with your finger and iron again.

Iron the initial fold as described above for a portion of about 1”-2” along the hem.

3. Working on the wrong side of the garment and using the pre-folded portion as a guide, wrap the hem edge around the guides of the hemmer foot such that each fold falls into the correct slot.

4. Guiding the fabric with a little tension, machine stitch as the hemmer foot simultaneously rolls the fabric raw edge in.

Try not to pull the fabric too much as you stitch. Pulling will not only cause the fabric edge to come out of the folding slots, the rolled hem may also result in distorted, stretched-out finish.

Mastering a hemmer foot will take some patience and practice, varying based on the type of fabric used. However, once you get the hang of it, it will save you lots of time (and headache!) when sewing with sheers.

5. As a final step, iron the finished rolled hem to achieve a smooth, flat finish. Use a heat protective cloth if pressing sensitive fabrics.