A fused hem finish uses fusible hem tape or webbing to bond and keep the hem allowance edge folded towards the wrong side of the garment. This method falls in the category of no-sew finishes.

When using the fusible hemming technique consider the garment’s desired longevity and how it will be cared for in the long run. Since the fusible adhesive replaces a machine stitch, it serves as the only means for keeping the hem layers connected. The adhesive, while meant to be permanent, can degrade over time, especially with regular machine-washing.

There are two main fusible hemming techniques:

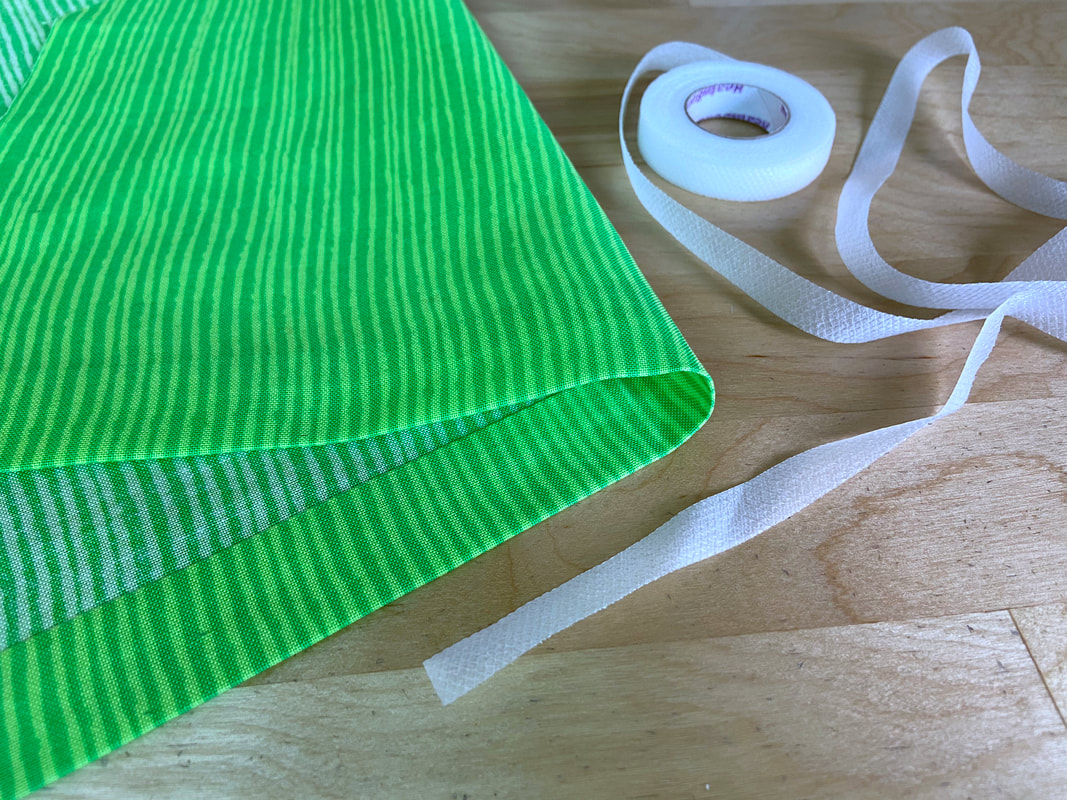

One uses a heat-bonding hem tape, which is thicker and comes in a precut width. You can find hem tape in a variety of widths from ¼” to 2” and beyond, all of which are conventionally purchased in a pre-packaged style. Use the width that works best with your fabric and hem allowance length. Naturally, a wider hem tape will have a stronger bonding effect.

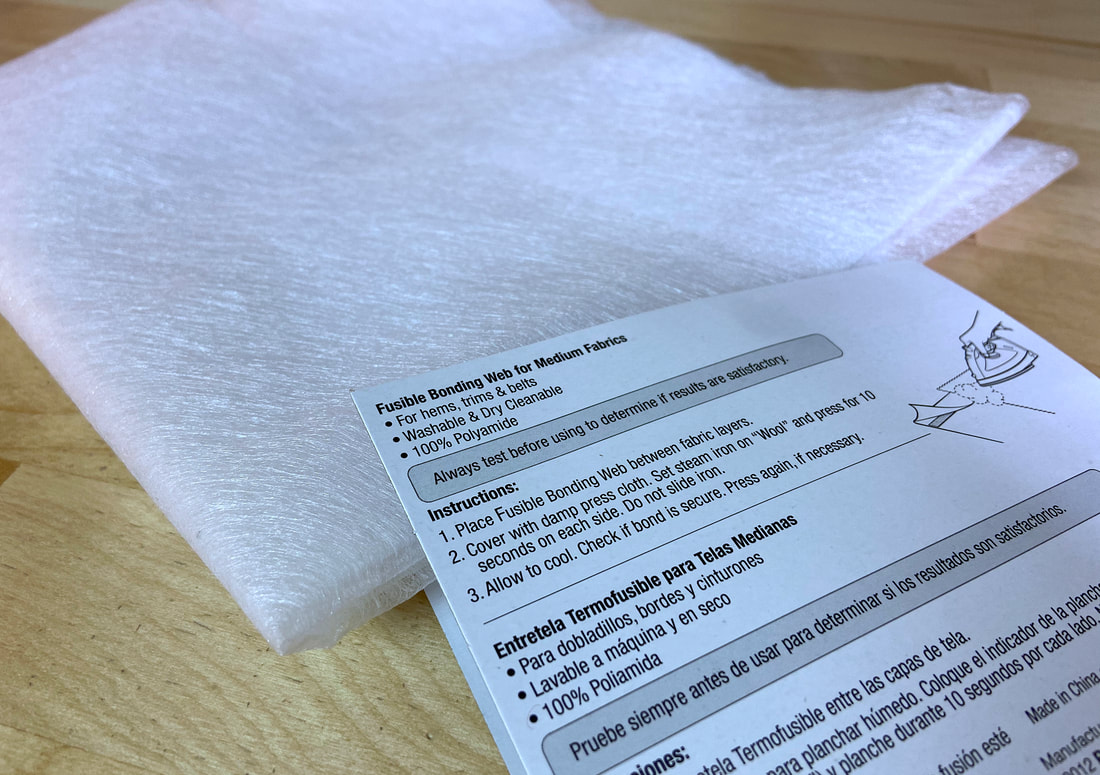

The second technique uses fusible web, which is an intermingling of fiber and adhesive that bonds fabric layers together with the addition of heat. Fusible web is available both in pre-cut form as well as per yard. The benefit of per-yard webbing is that it can be cut to whatever width needed for the project at hand.

As opposed to regular hem tape, fusible web is thinner and more sheer. Therefore, it has less of a negative effect on the drape and the addition of bulk in the finished garment.

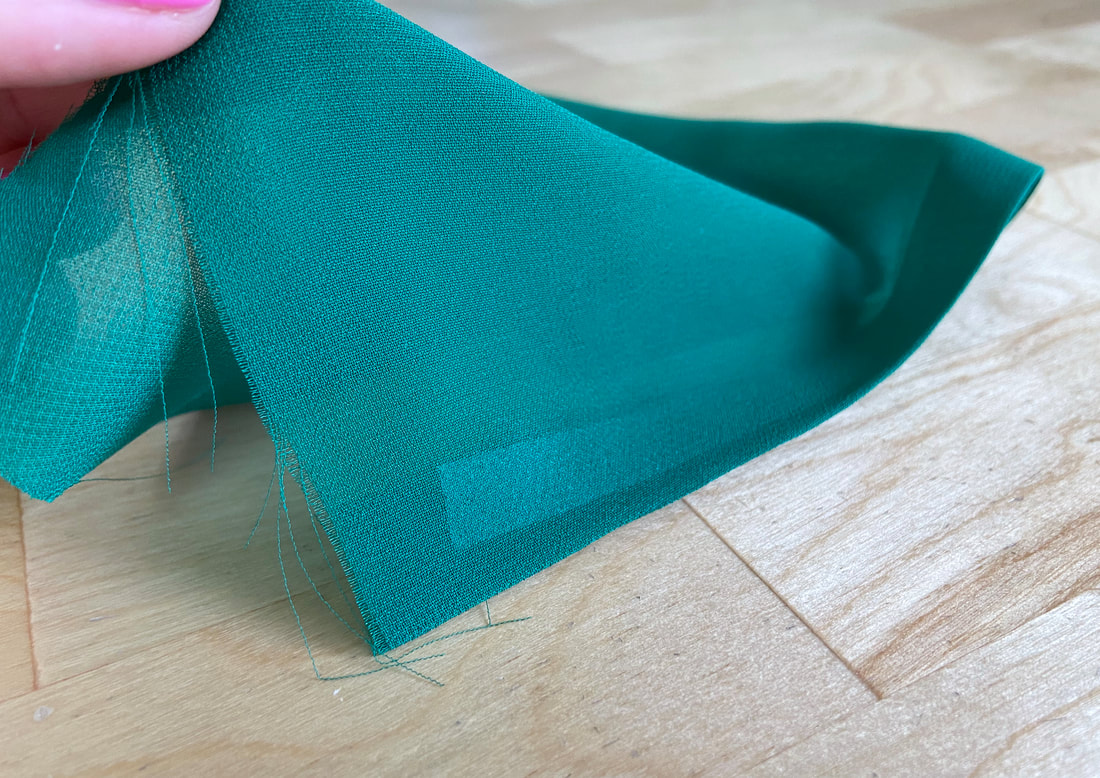

Not all fabrics are suitable for the fusible hemming technique. Many silk and sheer fabrics will experience some bleed-through from the fusible adhesive.

That being said, a fused hem finish works best with medium-to-heavy weight fabrics that are thick enough to withstand potential staining. They should also have a surface that is conducive to heat bonding.

Before using a fusible tape or webbing, always pretest a scrap piece of your fabric. After following all application directions properly, check that the fabric is fully bonded and the fusible adhesive doesn’t bleed through or stain the fabric.

It is also important to pay attention to how the addition of the fusible tape/webbing affects the drape and fit of the garment. Does it stiffen the hemline, negatively impacting its drape? If the answer is yes, it is best not to use this hemming technique even if the fusible tape adheres well to the fabric.

Most fusibles purchased at your local fabric store should come with application instructions. Be sure to follow them carefully as the quality and effectiveness of the finish depends highly on proper application.

Here are a few elements to consider when completing a fused hem:

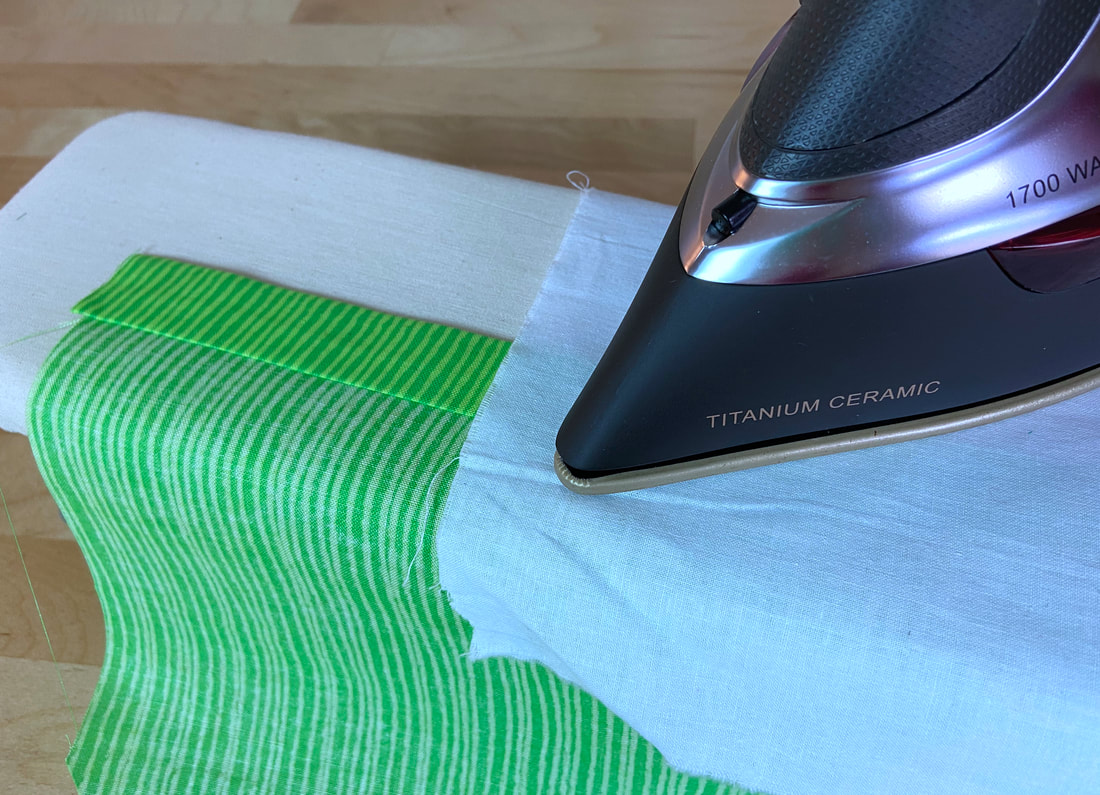

1. As opposed to running the iron over the fabric surface, hold the iron at different places and press. Doing so prevents the webbing/tape from sliding out of place underneath. This technique is called iron-basting and can be used to stabilize both fused hemlines and fusible interfacing prior to permanent application.

2. Fusible bonding is more permanent than stitching. Like glue, once applied, it is difficult to remove. Similar to fusible interfacing, if you pull the pieces apart, the adhesive will remain on the fabric surface. Therefore, always double check the final hem placement before permanently bonding the hem allowance layers.

On that note, do not let the fusible webbing touch the iron as it will melt over the metal plate. Once it does, it is difficult to clean.

3. To attach fusible webbing, use a damp cloth between the fabric and the iron plate. This will serve both as a protective shield, and help the webbing fuse and bond properly.

4. Try not to stretch the hem and/or the fusible webbing or hem tape during the alignment and application process as you risk breaking it. Be gentle as you carefully align it along the hem allowance edge.