Understanding Leather As A Material

Regardless of how it is used in dressmaking, leather always operates by its own rules. Whether it is authentic or faux leather, similar principles should be used when sewing the garment and finishing its hem.

The beauty of leather as a material is its simplicity. Three important concepts are at the heart of sewing leather:

- Leather, regardless of whether it is genuine or faux, cannot be pinned as you would with regular woven and knit fabrics. When inserted, pins leave permanent indentations on the leather’s surface.

If absolutely necessary, you can pin leather only through seam allowance when/if you are 100% certain the seams are final. If any finished seams have to be re-stitched, the previous stitching will leave permanent perforations on the leather’s surface.

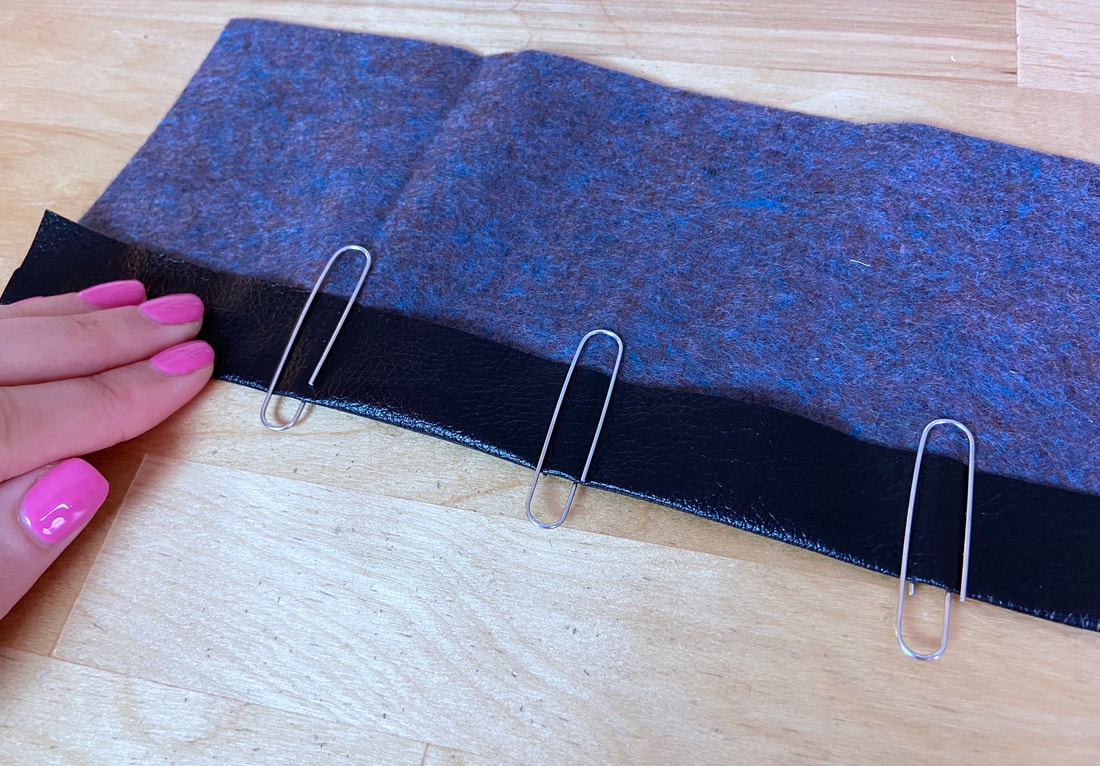

Instead of pins, use paper or binder clips to keep layers together for machine stitching.

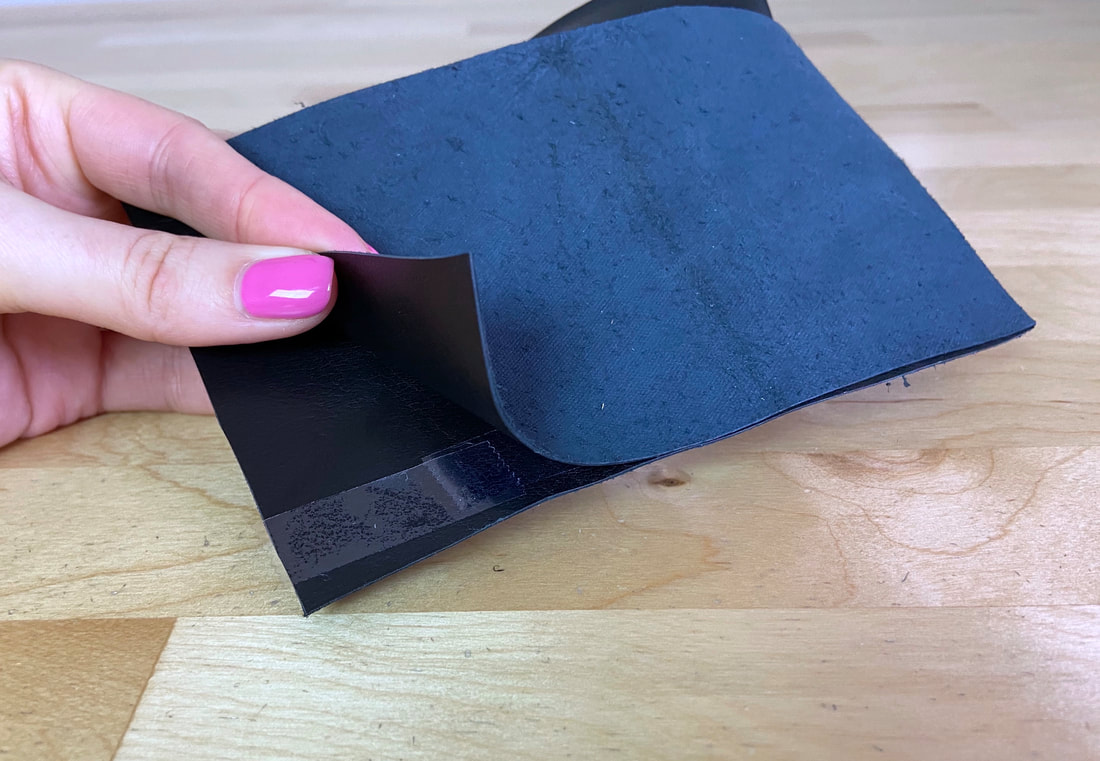

You can also use removable double-sided tape which should be available at your local fabric store. Before the final application, always test that the adhesive doesn’t permanently stain or damage the leather fabric.

When topstitching folded leather edges, finger pressing is often sufficient to keep the layers flat. If finger pressing is not enough, use a leather mallet to hammer the fold down.

- Leather does not fray thus no techniques to contain fabric raw edges are needed.

- Leather cannot be ironed. Faux leather, in particular, will easily melt under the heat of the iron. Because it is a structured material, leather is often finger pressed in the sewing process.

To keep seam allowance edges permanently down, leather seams can either be topstitched or hammered flat.

Topstitching works great with faux leathers.

Using a mallet or light hammer works best with authentic leather.

These three, universal leather-sewing “rules” should give you a better understanding of how to handle a leather hem.

There are two standard ways to finish a leather garment’s hem: topstitching the folded hem, or gluing the folded hem allowance layer. A few variations of these techniques are used with both fully lined and unlined leather garments.

How To Clean-Finish A Leather Hem By Topstitching

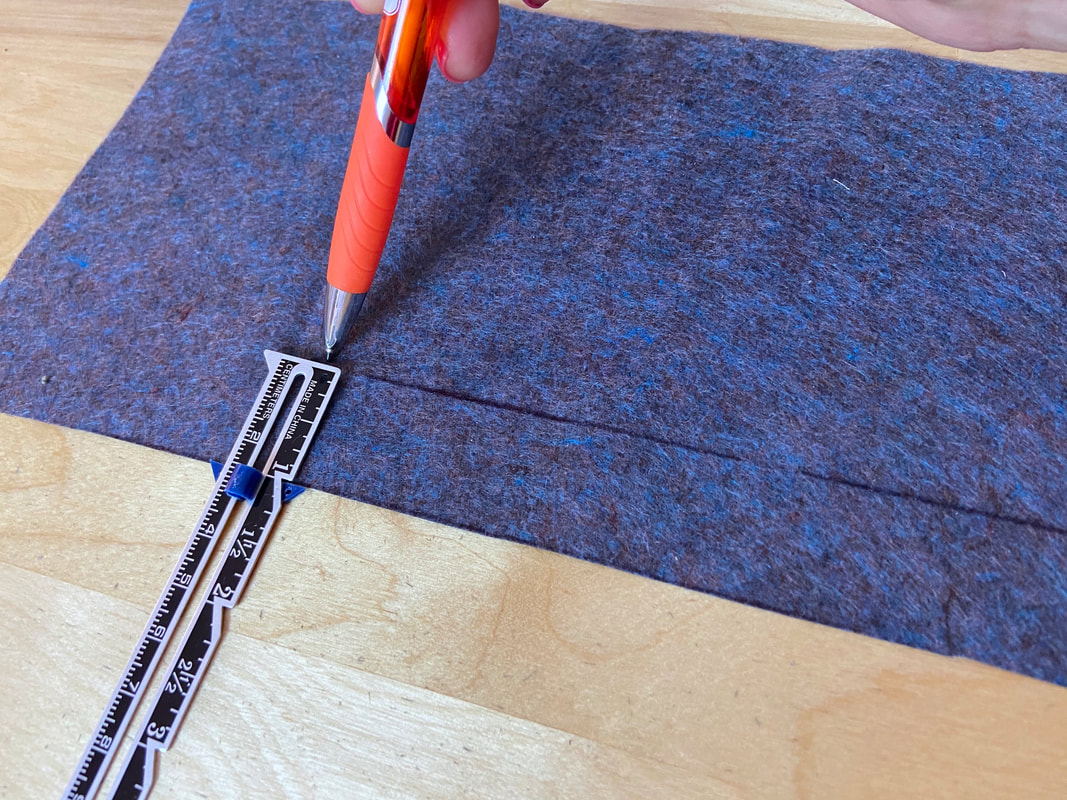

1. Determine your garment’s hem allowance by checking your patterns or sewing instructions (if any). In this example, the hem allowance is 1”.

Using a ruler (or gage pointer) and a pencil, measure the hem allowance width from the very bottom edge up, and mark the entire hemline as shown.

2. Fold the bottom cut edge towards the wrong side of the garment such that the folded edge falls directly on the marked hemline in Step 1.

3. Finger press and insert paper clips along the folded edge to keep it secured. Continue folding and securing with paper clips until the entire hem is completed.

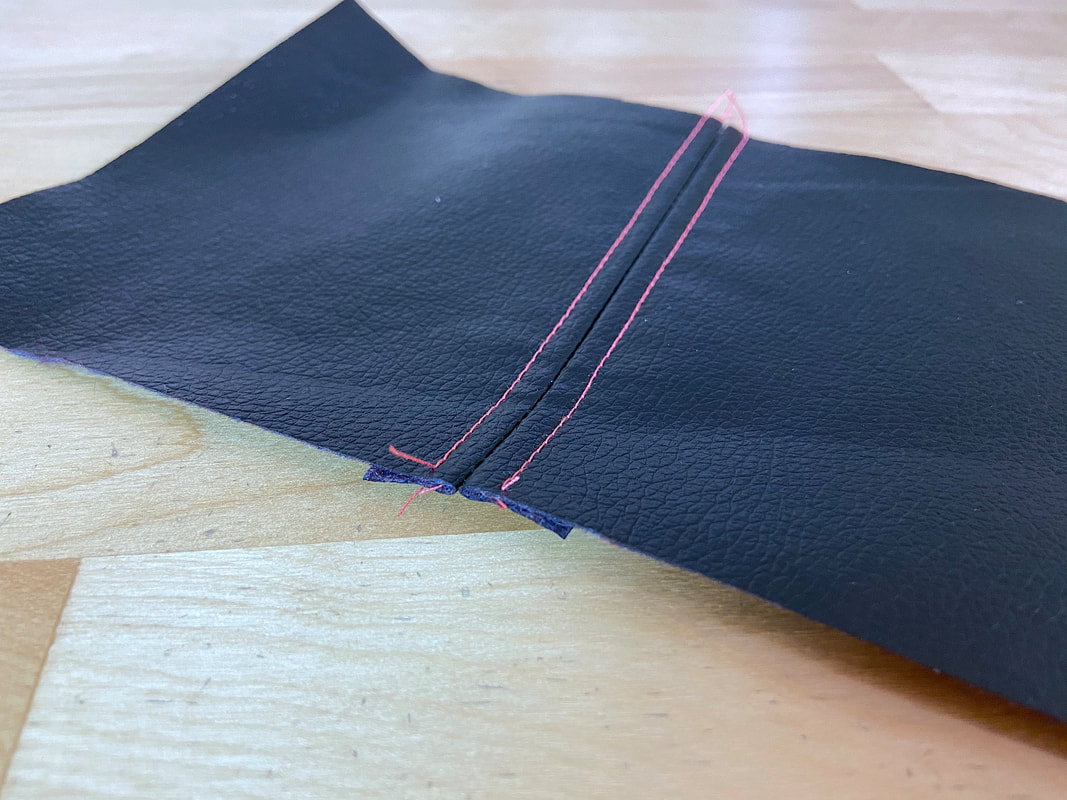

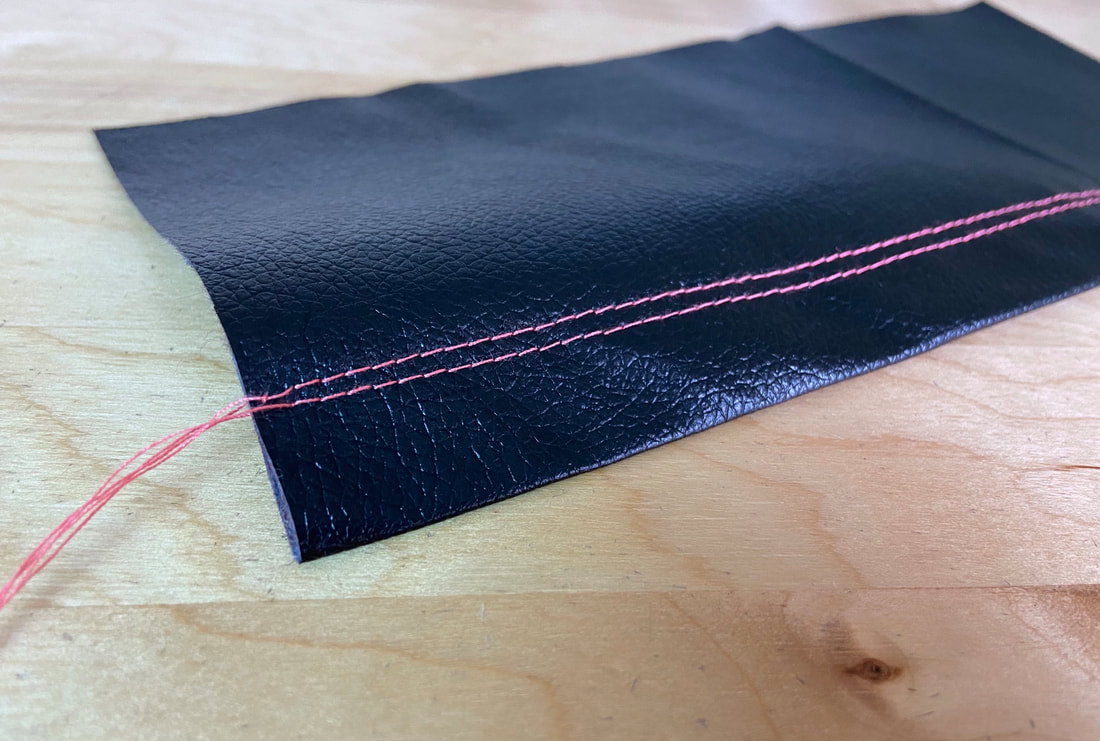

4. With the garment wrong side facing up, topstitch through the hem allowance and garment layer underneath at approximately 1/4” distance from the cut edge as shown.

5. For a more traditional visual effect, add another row of topstitching below the one applied above. You can place this second row of topstitching anywhere from 1/8” to 1/4” away from the first.

6. For a smooth, flat finish, use a mallet to hammer down the finished hemline edge on a flat, sturdy surface.

Note: If you prefer the topstitching to be closer to the garment’s finished hemline, trim the hem allowance down to ½” before folding and topstitching it as described in the steps above.

How To Finish A Leather Hem With Rubber Cement/Glue

To finish a leather hem using the adhesive method, it is important to first choose the right adhesive for the job.

Leather/rubber cement is a good, clean option. There are a variety of other options on the market that are designated specifically for use with leather.

1. Repeat the process described in Step 1 above to measure and mark the hemline on the wrong side of the leather garment.

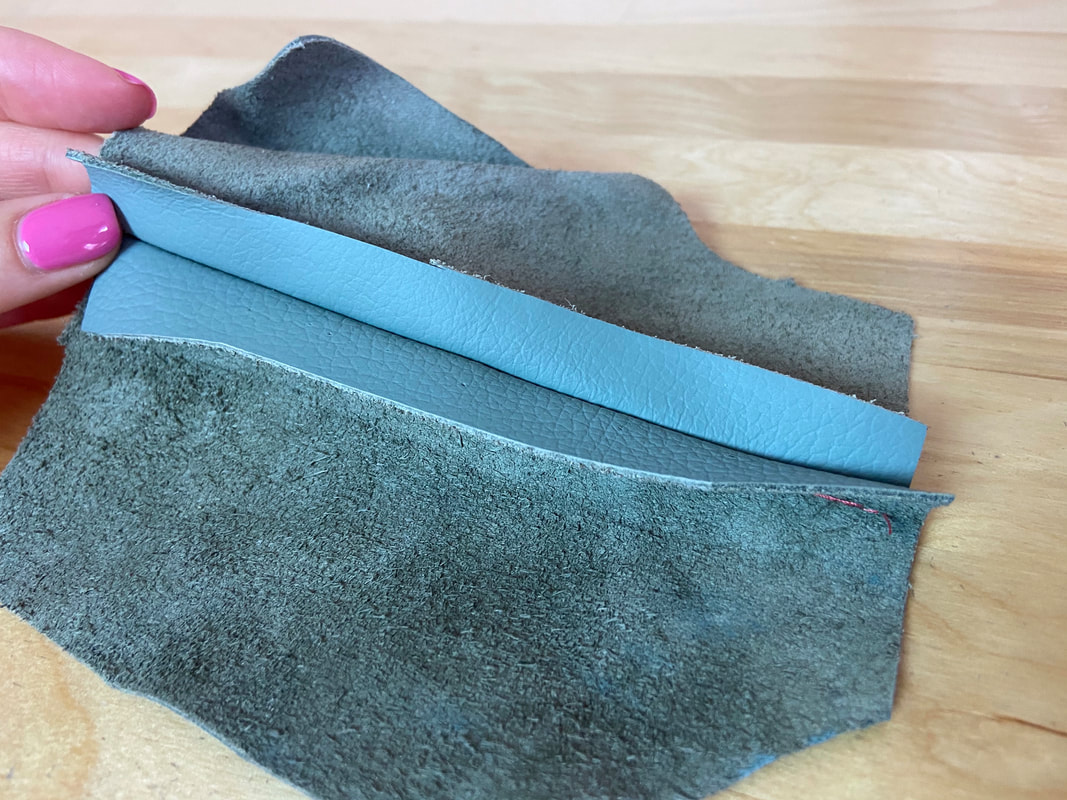

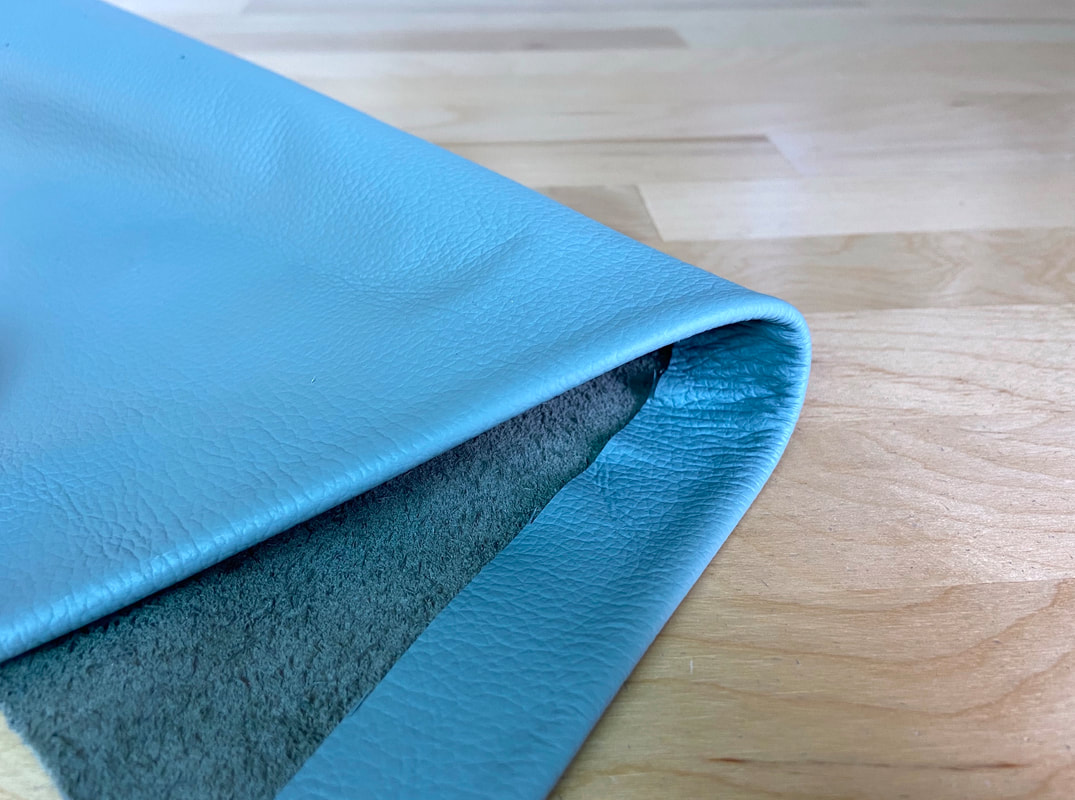

2. Before applying the adhesive, fold and finger-press the hem allowance along the marked hemline. If the fold does not crease with hand pressing, flatten it with a mallet.

3. Apply leather cement (or your choice of leather glue) to the entire surface of the hem allowance and the portion above the hemline that will naturally be covered when the hem allowance is folded up.

Use a light coat, but not so light that it doesn’t adhere completely. For best results, carefully read the instructions on your adhesive choice.

4. Carefully press the hem allowance up towards the wrong side of the garment. Use the crease from Step 1 as a guide to naturally direct the hem allowance in place. The fold line should correspond to the finished garment hemline.

Finger press the hem allowance down as you fold until the entire length of the hem allowance is secured.

5. To reinforce, hammer the layers together again with a mallet. The result should be a smooth, flat hemline finish.

6. Leave the folded hemline to dry as indicated by the adhesive instructions.