What Is An Even Slipstitch?

An even slipstitch is a form of blind stitching used to join two folded or finished edge together in an abutted style. This hand stitch is used quite often when repairing seams by hand, especially if they are difficult to machine stitch.

Slipstitching can also be used to sew a seam from the garment’s right side if needed in the fitting process (on a dress form, for example). An even slipstitch is essentially invisible since the thread is pulled through the folded edges thus hiding it in between the fabric layers.

How To Apply An Even Slipstitch

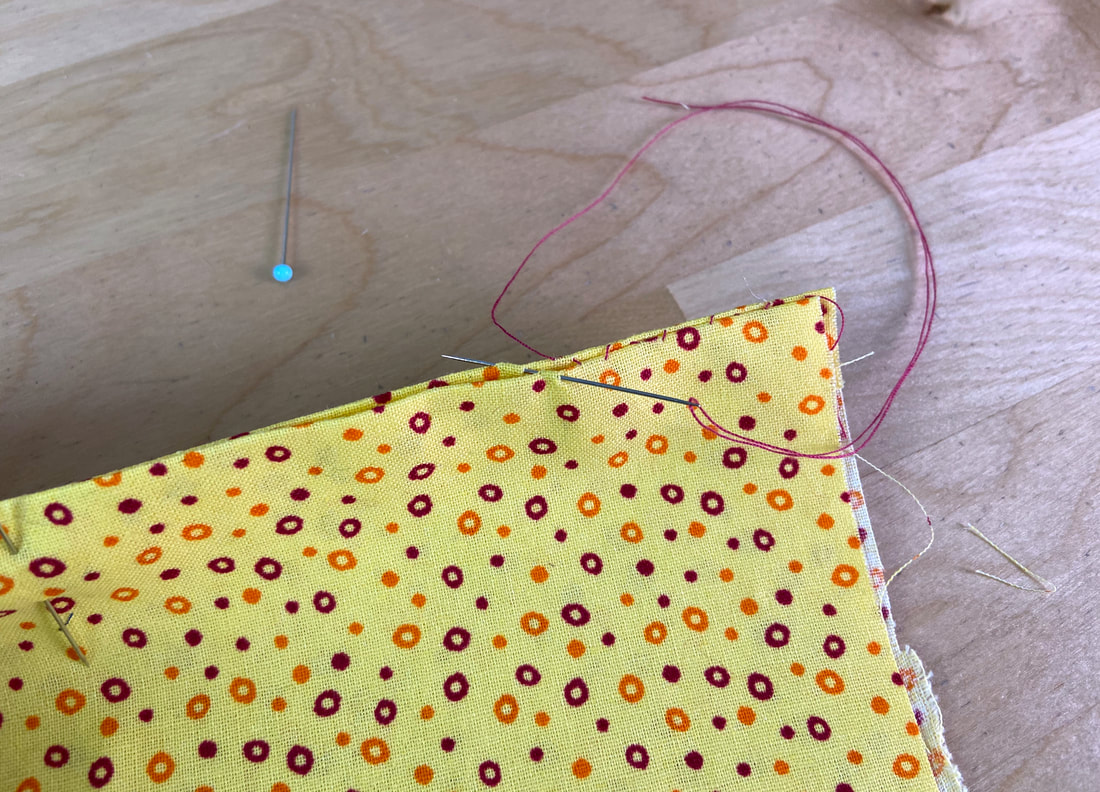

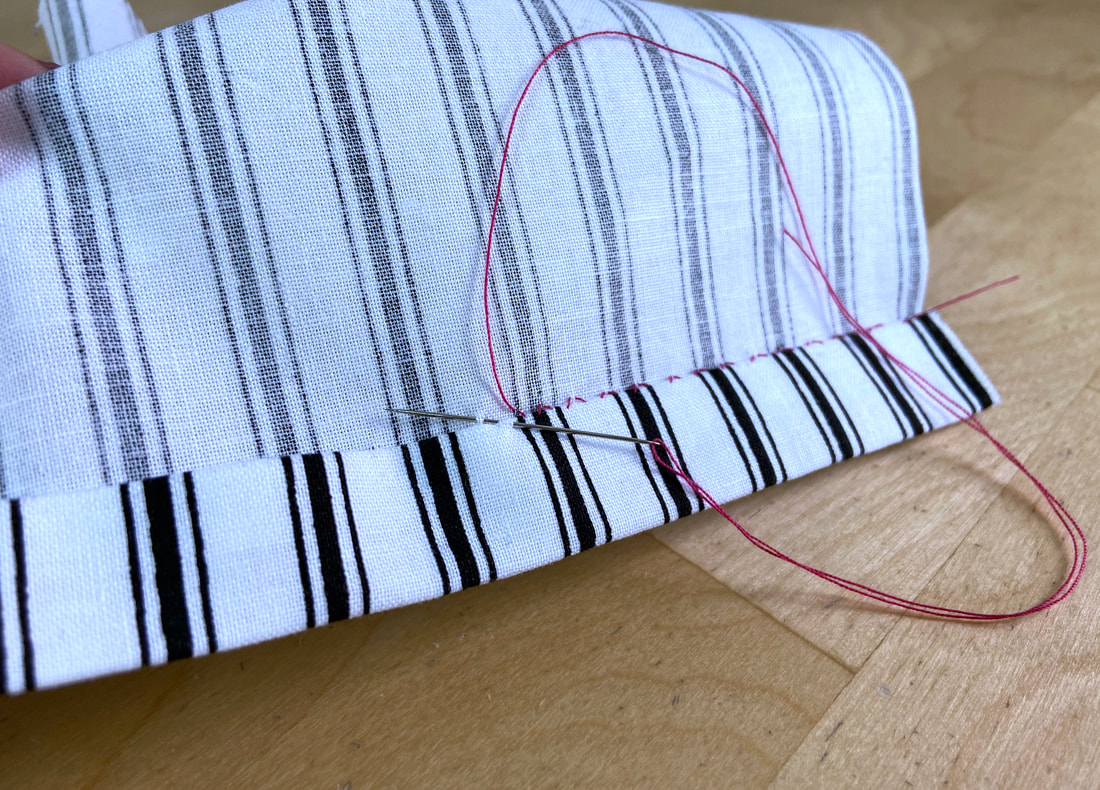

1. Align and pin the finished/folded edge together as shown.

2. Insert the needle through one of the folded edges such that the thread is hidden in between the fabric layers. Apply a ¼” stitch through the fold.

3. Next, stitch trough the other folded edge in the same manner, again, applying a ¼” stitch.

4. Repeat the stitching process alternating from fold to fold, connecting the two edges in the process. Since all stitches are enclosed between the fabric layers, there should be no visible thread on the face of the seam. If matching color thread is used, the slipstitch completely disappears into the abutted seam.

What Is An Uneven Slipstitch?

Uneven slipstitching is used when blind stitching a folded edge to the fabric surface. As noted above, a conventional slipstitch is a high-quality finish that leaves (almost) no visible stitching on both the face and wrong side of the application. The uneven style is most commonly used as a blind hemming technique. It can also be used to attach appliques, trims and patch pockets to the garment surface.

As is true for all slipstitched applications, the thread is hidden within the folded edge. When using matching-color thread, the stitch becomes almost invisible.

To slipstitch a separate fold to the fabric surface, only 1-2 threads from the fabric surface are caught in the stitching process. Uneven slipstitching is one of the highest quality blind-hemming techniques used most commonly with folded hemlines.

How To Sew An Uneven Slipstitch

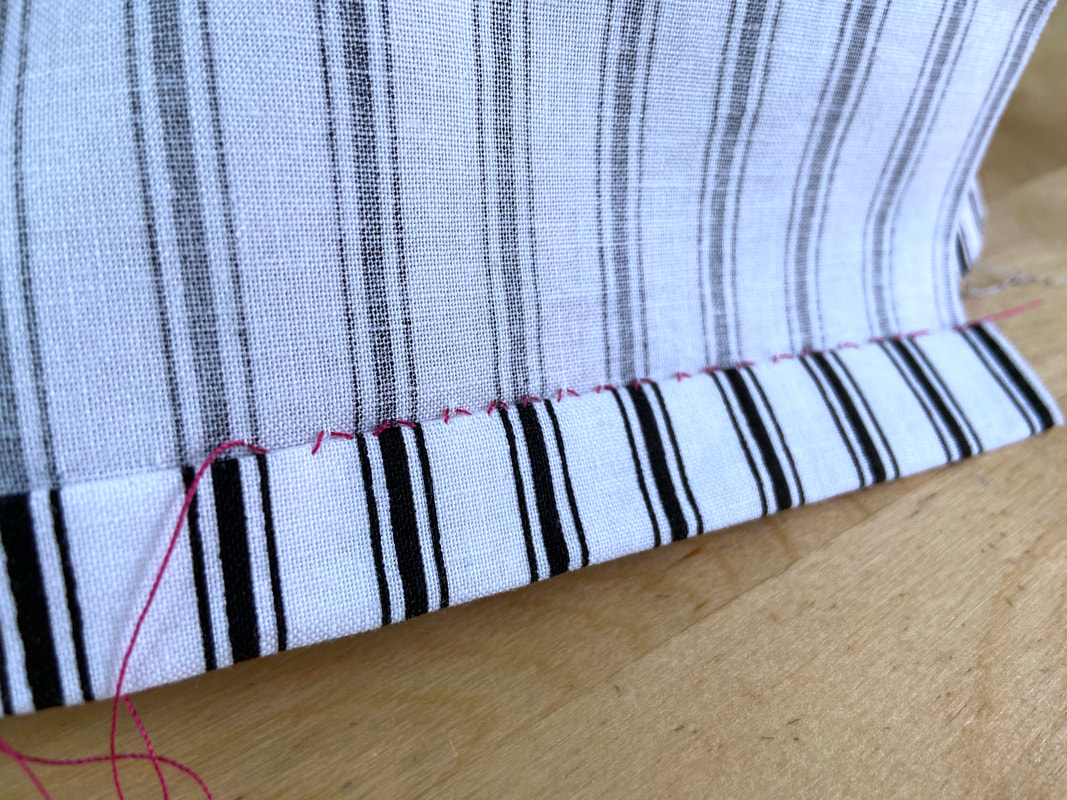

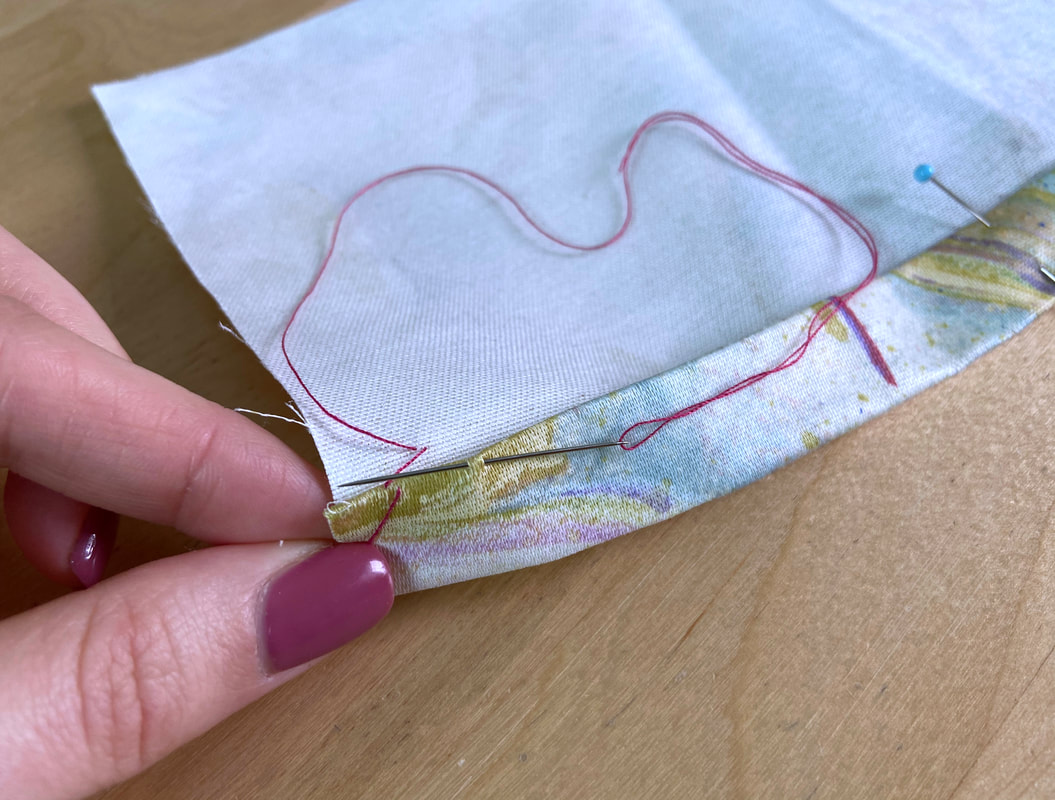

1. Insert a stitch through the folded fabric edge at about ¼” distance and pull the thread through. The thread should be enclosed within the layers of the fold.

2. Next, catch 1-2 threads from the fabric surface and insert the needle back through the folded edge at ¼” again.

3. Repeat the alternating fold and surface stitches to connect the folded edge to the garment’s surface. The stitch should look invisible on both the right and wrong side of the garment.

You can determine how small or long the stitches should be based on the fabric’s weight and how durable the connection needs to be. A thicker, more textured fabric will work better with a longer, less dense slipstitch.

What Is A Blind Hemming Stitch?

A blind hemming stitch is a quick and effective way to finish a garment’s folded-up hem. It works just as well with single fabric layers as it does with folded edges (although a folded edge works better with a slipstitch).

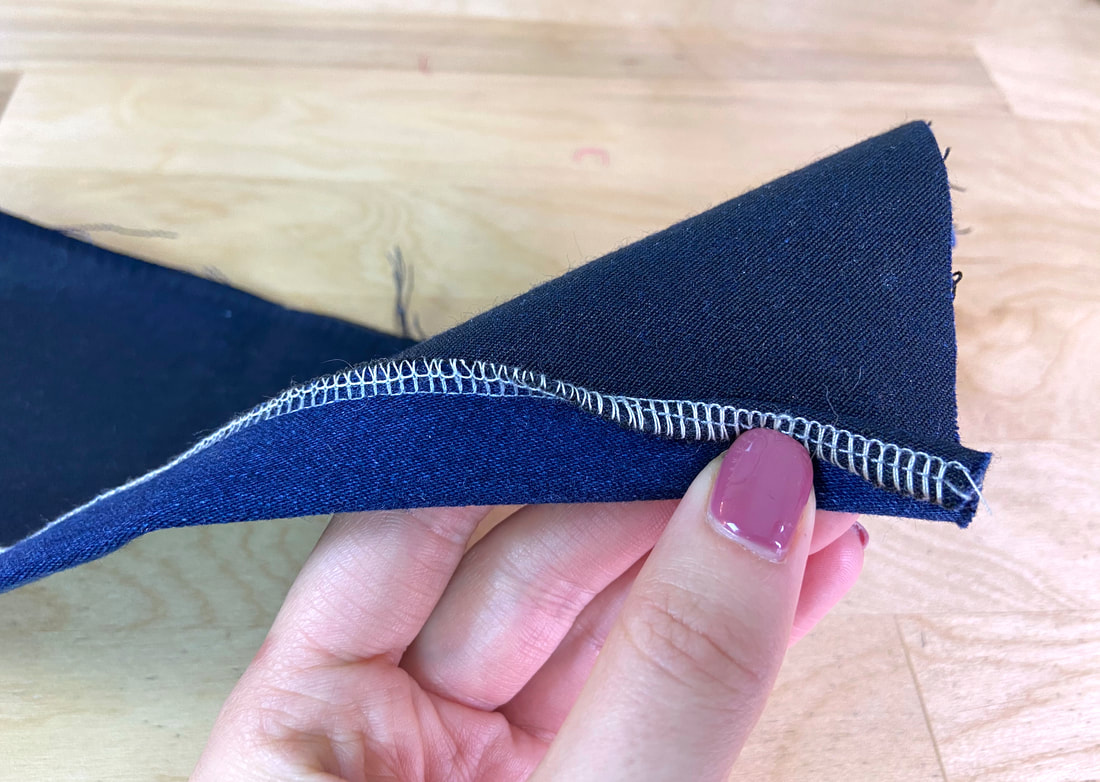

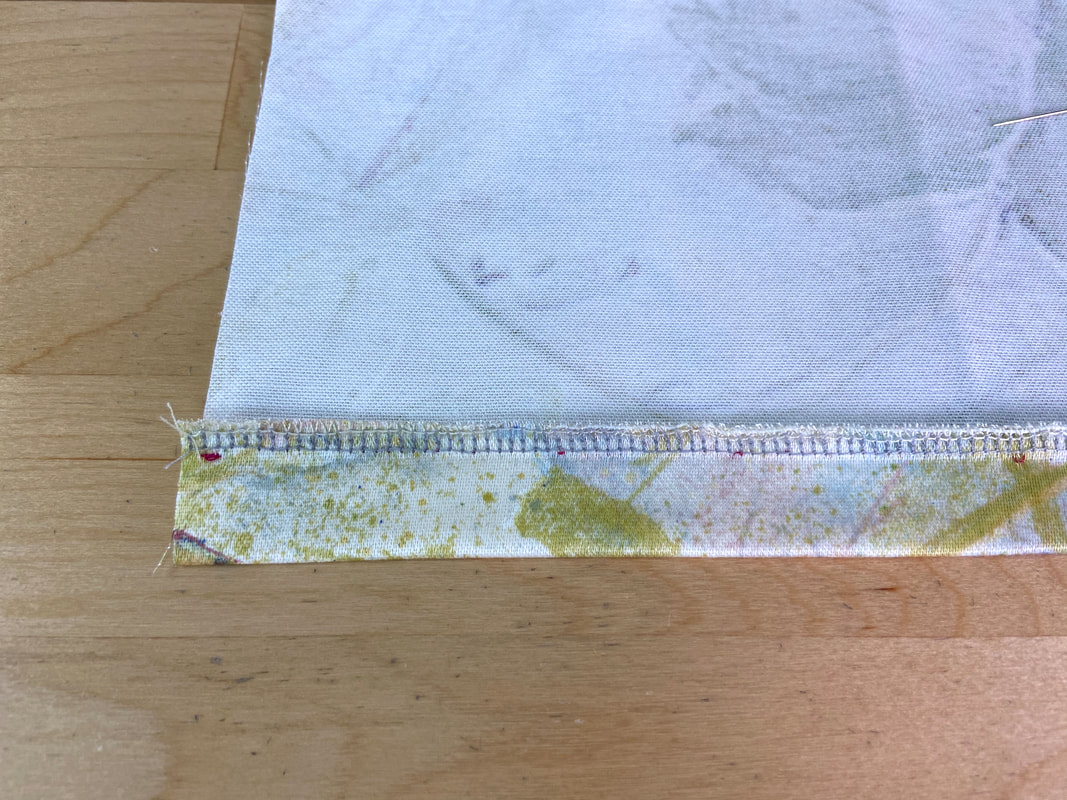

A blind hemming stitch is applied underneath the fabric edge to connect the edge to the fabric surface such that it is hidden under the folded-up layer as shown. If the fabric unravels when cut, always apply an overedge finish such as serging or zigzag before blind hemming the edge to the garment surface.

How To Sew A Blind Hemming Stitch

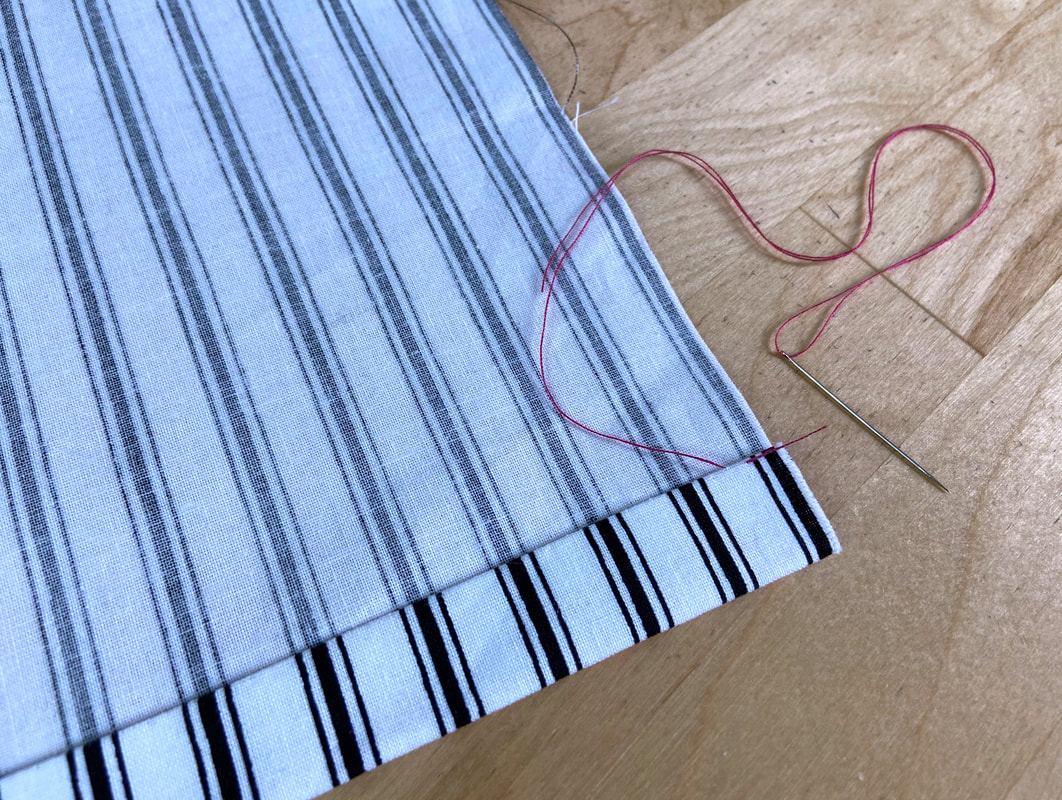

1. Fold the top edge of the folded fabric back such that its wrong side is exposed.

2. Catch a few threads from the wrong side of the edge as shown.

3. Next, catch 1-2 threads from the garment surface and continue stitching back through the wrong side of the fabric edge catching about 1-2 threads again. This will create a V-like stitch alternating from the fabric surface to the inside of the folded edge.

4. Continue alternating between the edge and fabric surface to complete the blind hemming application. As a result, there should be no visible stitching on either the face or wrong side of the garment.

What Is A Visible Catchstitch?

A catchstitch is another hand-applied hemming stitch used to attach a single fabric edge to the fabric surface. A catchstitch looks similar to the blind hemming stitch described above but it is a little more durable since the thread crosses over itself at each connection.

A visible catchstitch is applied over the fabric edge, connecting back to the fabric surface at the top. It may be easiest to apply the stitch left to right. To achieve the crossing-thread effect, the needle will has to point in a single direction (either left or right). It may take a little time to get the rhythm down but once you do, this is a great way to blind stitch the hem of thicker more structured fabrics.

How To Sew A Visible Catchstitch

1. Insert a small horizontal stitch through the folded fabric edge catching just the top fabric layer as shown.

2. Next, insert the needle from right to left horizontally through the fabric surface above the fold as shown- This will leave another small horizontal stitch through the fabric surface.

3. Next, apply another right-to-left horizontal stitch through the fabric fold at an equal distance from the previously-applied stitch.

Inserting the needle horizontally from right to left will naturally create the crossing threads. When complete, the catchstitch should resemble a zig zag pattern.

4. Repeat the stitching process described above to connect the rest of the fabric fold to the fabric surface underneath.

What Is A Blind Catchstitch?

A blind catchstitch is applied exactly the same as the visible one described above but instead of stitching over the edge/fold, the blind version is stitched on the inside of the folded-up hem allowance such that the stitch is hidden underneath. This application is identical in placement to the blind hemming technique described above.

How To Sew A Blind Catchstitch

1. Fold up the hem allowance at the designated length. In this case the hem allowance is 1”. Before folding, be sure to apply an overedge stitch or any other finish of your choice to contain the fabric's raw edge. Iron and pin the fold in preparation for stitching.

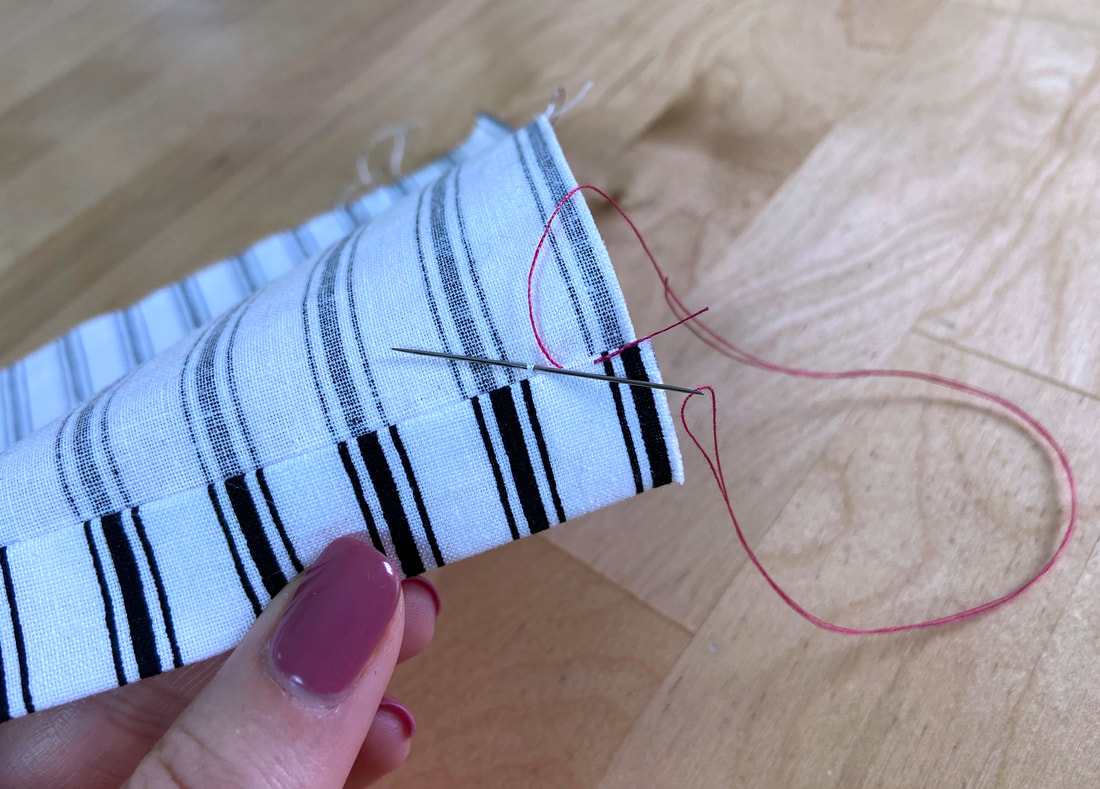

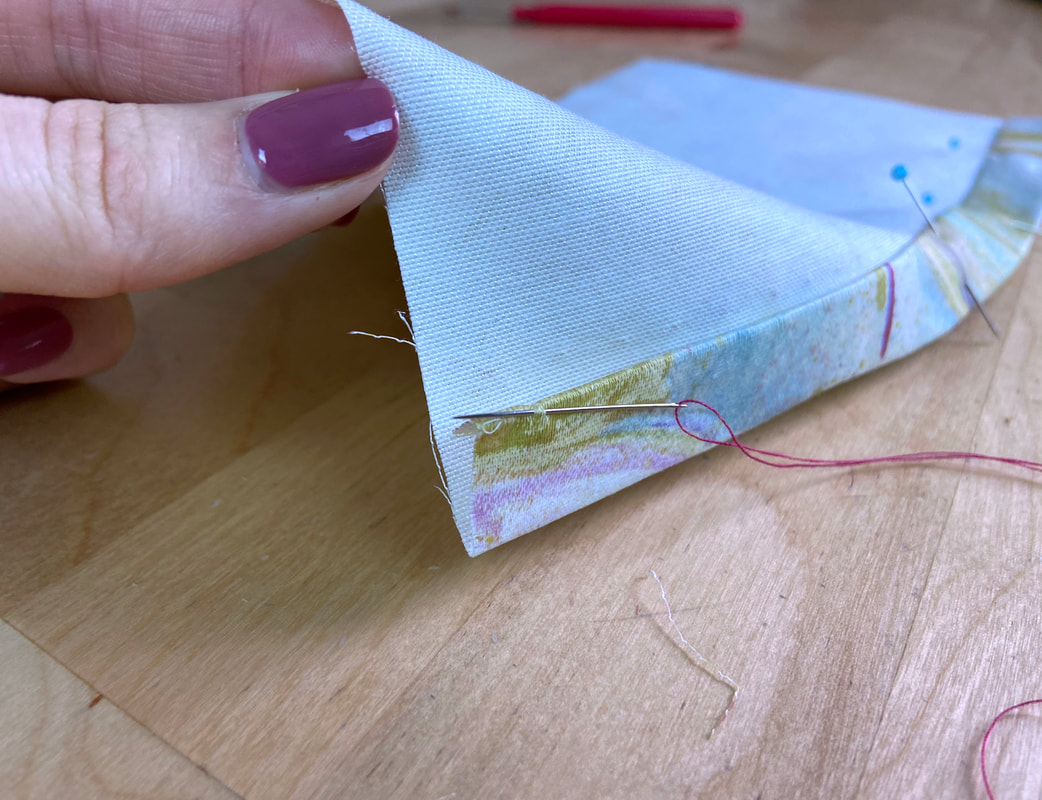

2. Fold back the fabric edge by approximately ¼” to expose its underside as shown.

3. Working from left to right, apply a catchstitch connecting the underside of the fabric edge to 2-3 threads from the garment surface.

To catchstitch, insert a stitch horizontally through the underside of the folded edge, then take another horizontal stitch through 2-3 threads of the garment surface.

Continue applying the alternating stitches until the entire edge is connected. A catchstitch creates crossing Vs along the entire application.

4. As a final step, fold the hem allowance edge back in its natural (initial) position and give it one last press to complete the finish.

As opposed to the visible application outlined above, a blind catchstitch is practically invisible on either side of the garment.