1. Add interfacing along the neckline and opening edges of the garment. The interfacing should be adhered to the wrong side of the garment layers. At the opening edge, the interfacing usually stops at the facing’s fold line (corresponding to the finished garment edge) or a little past it.

2. Before you begin sewing any seams, staystitch both the facing and garment neckline edges individually.

Staystitching is a straight stitch applied at about ¼” into the seam allowance of curved edges (or those prone to stretching), to prevent them from losing their shape during the construction process.

3. After the neckline edges have been staystitched, align the facing shoulder seam edges and the corresponding garment shoulder seam edges such that the fabric face sides are touching. Insert pins horizontally to maintain the alignment. Hand baste for extra stability if needed.

4. Machine stitch the shoulder seams at the designated seam allowance. ½ in this case.

5. Trim the seam allowance down to half its width to minimize bulk and then iron the seam allowance open from the wrong side of the seam as shown.

6. At this point, apply your choice of finish to the outer edge of the facing. You can choose between these common techniques as applicable to your project: Finishing Facing Edges

Note: If the facing will be sewn to lining, you do not need to finish the outer edge of the facing.

In this example, the extended facing edges are finished with a serging stitch.

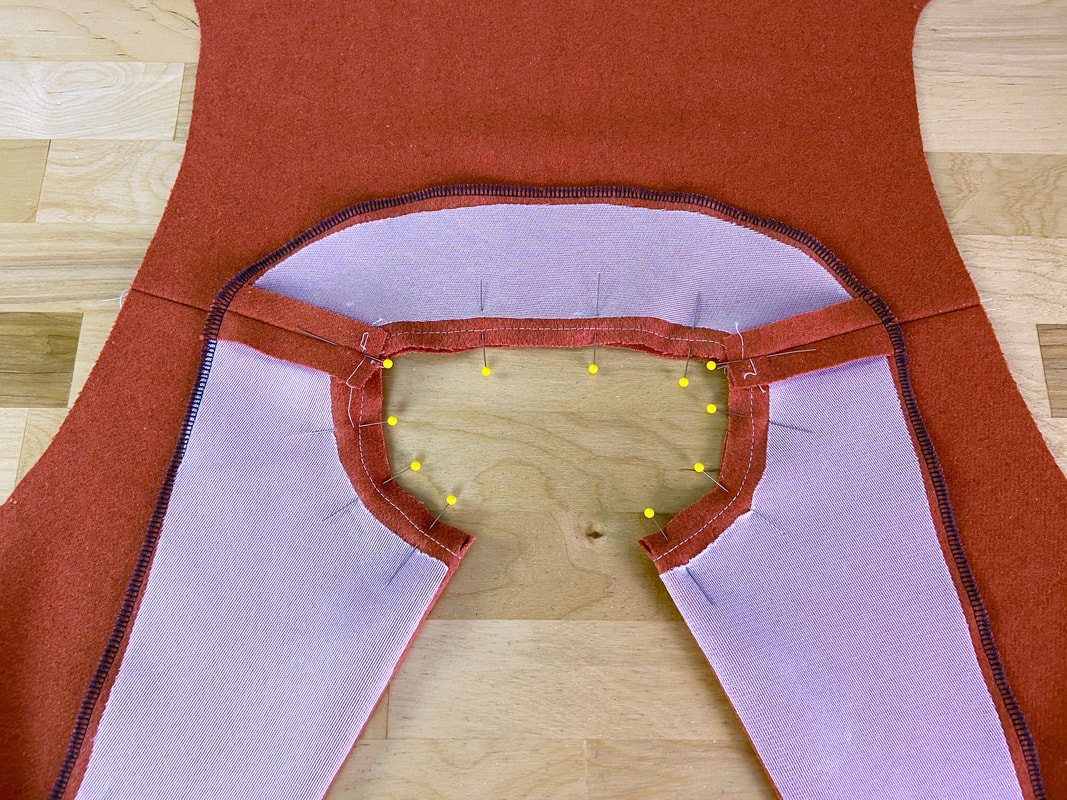

7. Next, fold the extended facing over the outside of the garment such that the fabric face sides are touching and the neckline edges of both facing and garment align.

Match the facing shoulder seam to the garment shoulder seam on each side, and insert pins to secure each seam alignment.

8. To secure the rest of the neckline, continue matching the facing and garment neck edges and insert pins horizontally through both fabric layers as shown.

9. For extra stability during machine stitching, apply a hand basting stitch right next to the seamline to secure the facing and garment layers together.

10. Starting on one side of the garment opening, stitch the facing to the garment neckline carefully, following the appropriate seam allowance guide (1/2” in this case). Stitch the neckline until you arrive at the other end of the garment opening. The stitch should be a smooth, curved line evenly distributed in relation to the outer edge. Remove the basting once the stitch is complete.

Be sure to backstitch at the beginning and end of the stitch.

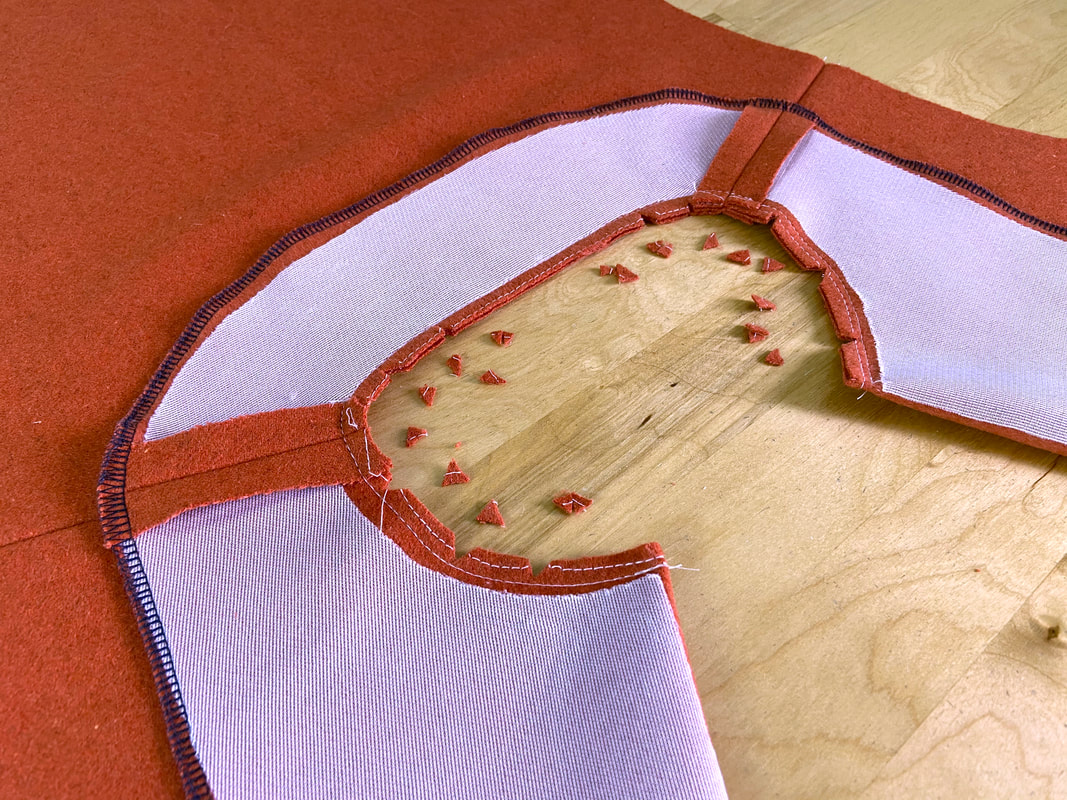

11. Before turning the facing on its right side, trim and grade (if needed) the seam allowance to minimize bulk.

12. Cut wedge notches into the seam allowance to release tension but be careful not to accidentally cut through the stitching in the process.

13. At the garment opening edges, trim the seam allowance diagonally across each corner.

14. Keeping the facing and its seam allowance pointing away from the garment, iron the facing seam carefully. It helps to use a tailor's ham or sleeve board to get as close to each folded end as you can.

15. Next, understitch at about 1/8” away from the facing seamline, through the facing and seam allowance layers underneath.

16. Turn the facing towards the inside of the garment and iron the finished neckline edge and garment opening fold on each side.

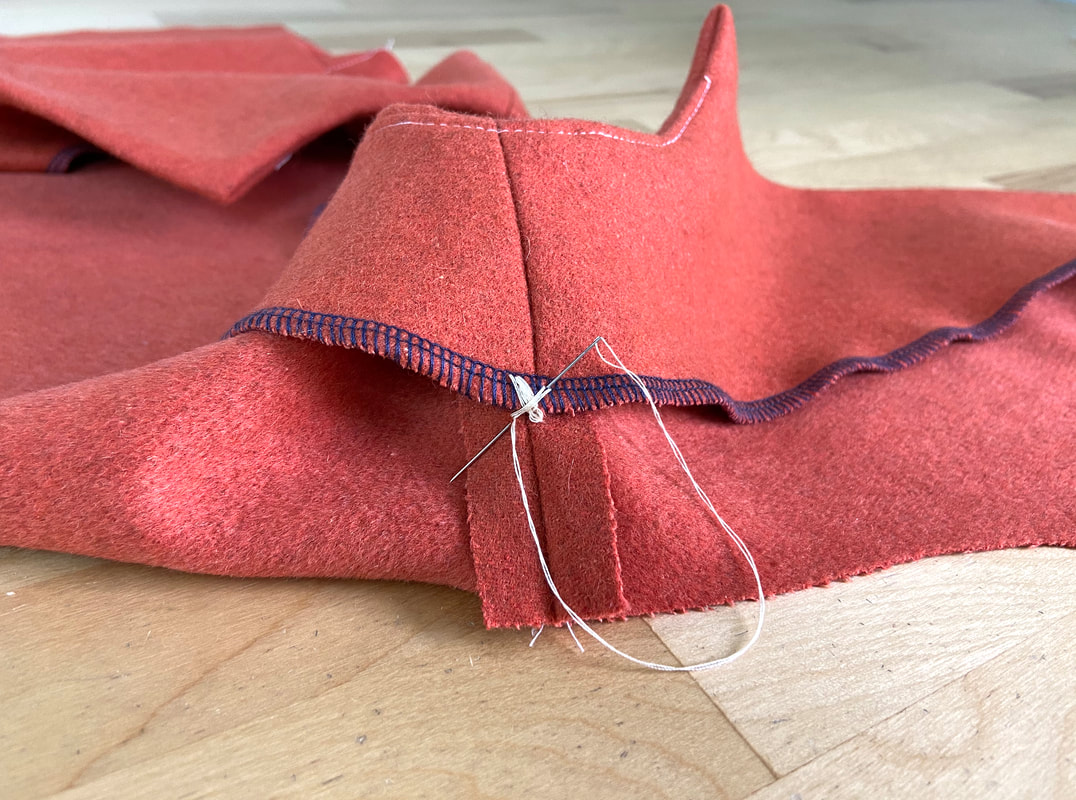

17. Last but not least, turn the entire garment on its wrong side, and tack the facing edge to the garment seam allowance at each shoulder seam. This hand stitch should not be visible on the outside of the garment but will help to keep the facing flat and pointing inward at all times. In this case, you can use a whipstitch or a cross tack.

Learn how to apply tack stitches in this tutorial: Hand-Applied Tack Stitches