Corded seams are fun and rewarding to sew. A corded seam is a purely decorative seam, very often used in quilting and outerwear.

This decorative seam uses a cording or piping tape to add a tubular cord along the seamline.

Cording, also known as piping, is a trim purchased separately and available in a variety of different colors, fabrics and finishes. While the most readily available piping is made of cotton and comes in a package similar to bias binding, other common styles are made of silk, satin, leather and suede.

Similar to bias binding, you can easily make piping tape at home. All you need is your choice of fabric, cord and a zipper foot enabling you to stitch right next to the raised cording edge. For extra stretch and flexibility, the fabric strip used to construct cording is cut on the bias.

How To Sew A Straight Corded Seam

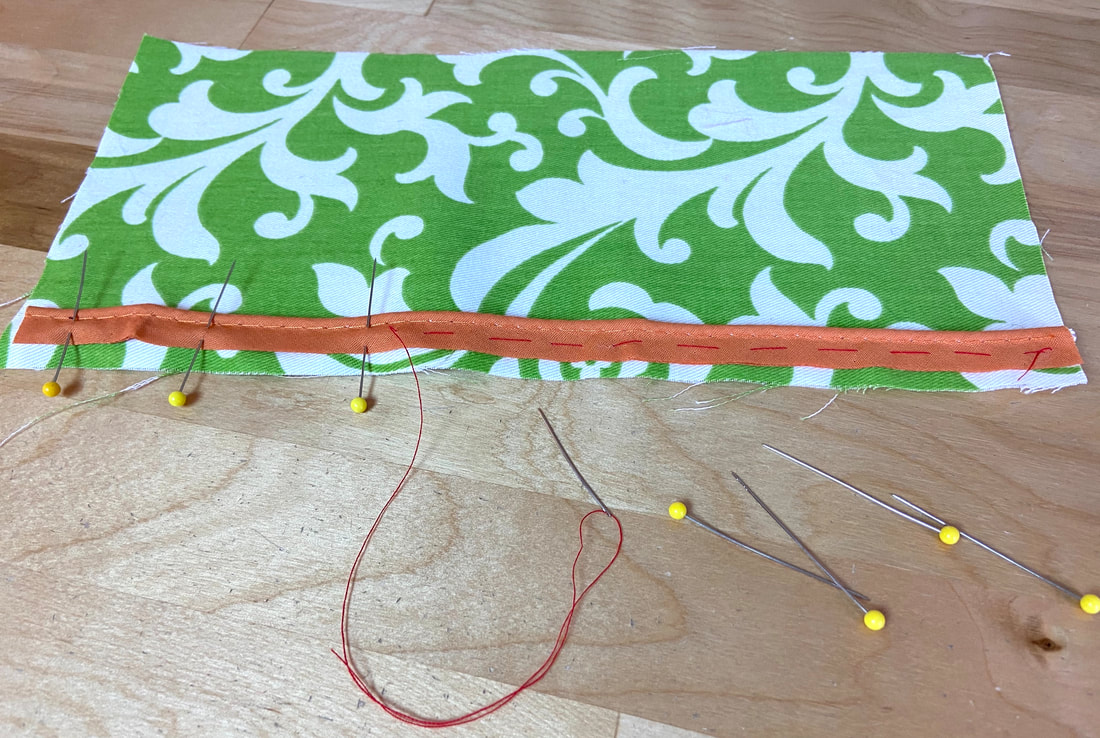

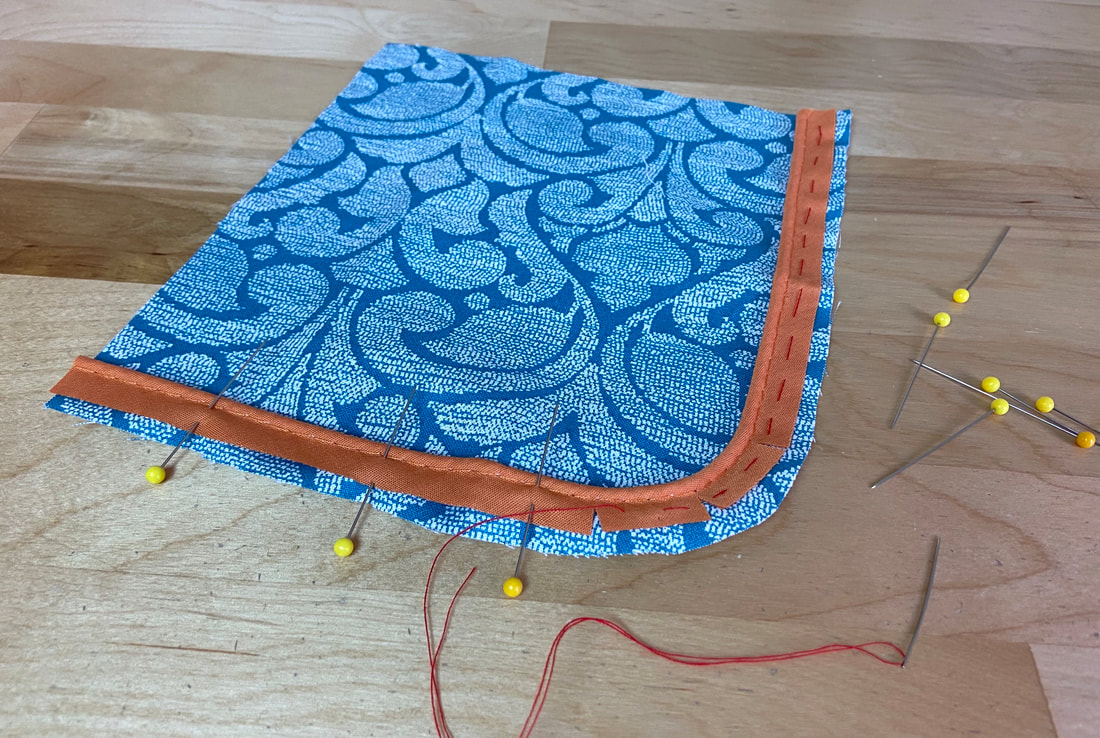

1. First, align the strip of cording tape along one of the seam edges such that the stitching on the tape aligns with the fabric’s seamline. The raw edges of the cording should be aligned in the direction of the seam edge. The actual corded edge should align with the inside of the seamline and will be the only portion visible on the finished seam. Insert pins perpendicularly through the cording tape and fabric edge.

2. Apply a hand basting stitch through both layers for extra stability.

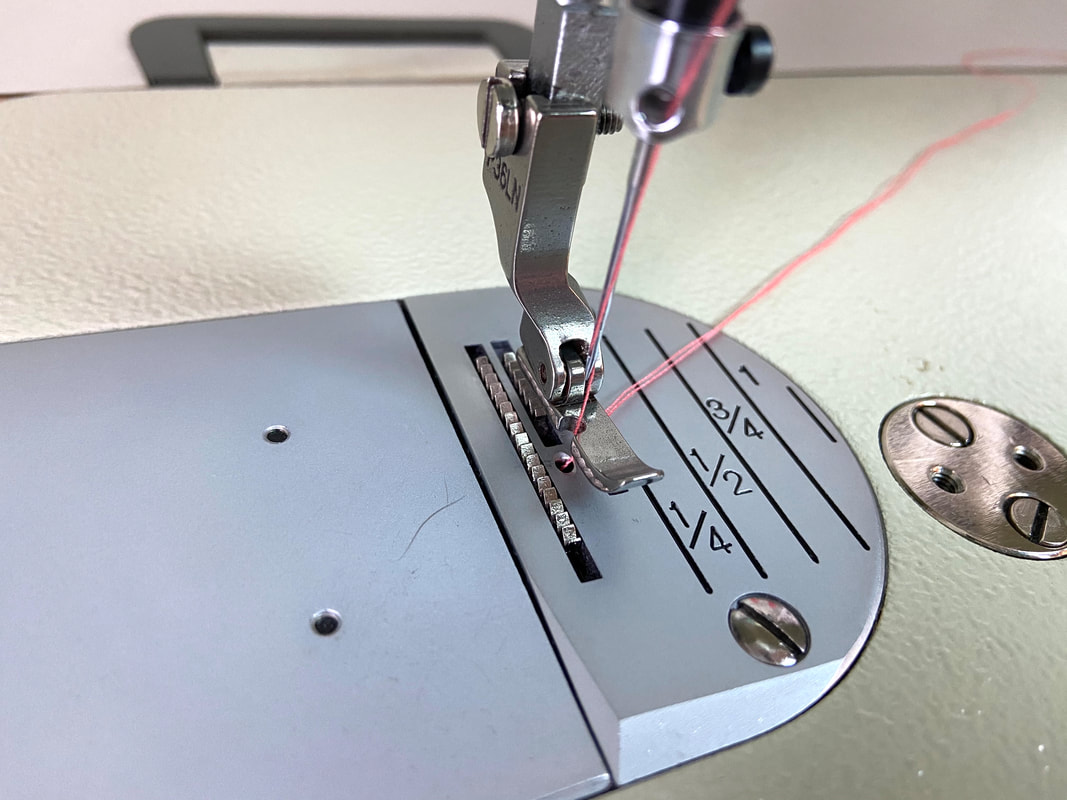

3. Switch your machine’s regular presser foot to a zipper foot. If unsure how to do this, follow your sewing machine manual. Switching presser feet should be fairly intuitive and is often as easy as a simple snap.

Cording is stitched using a regular zipper foot. A zipper foot is thinner than a regular presser foot. As opposed to aligning the machine needle right in the middle, a zipper presser foot aligns the needle either to its right or left side. This allows the needle to stitch right next to raised edges like those of cording and zipper teeth. A zipper foot is perhaps the most commonly-used presser foot, coming in second from a regular stitching foot.

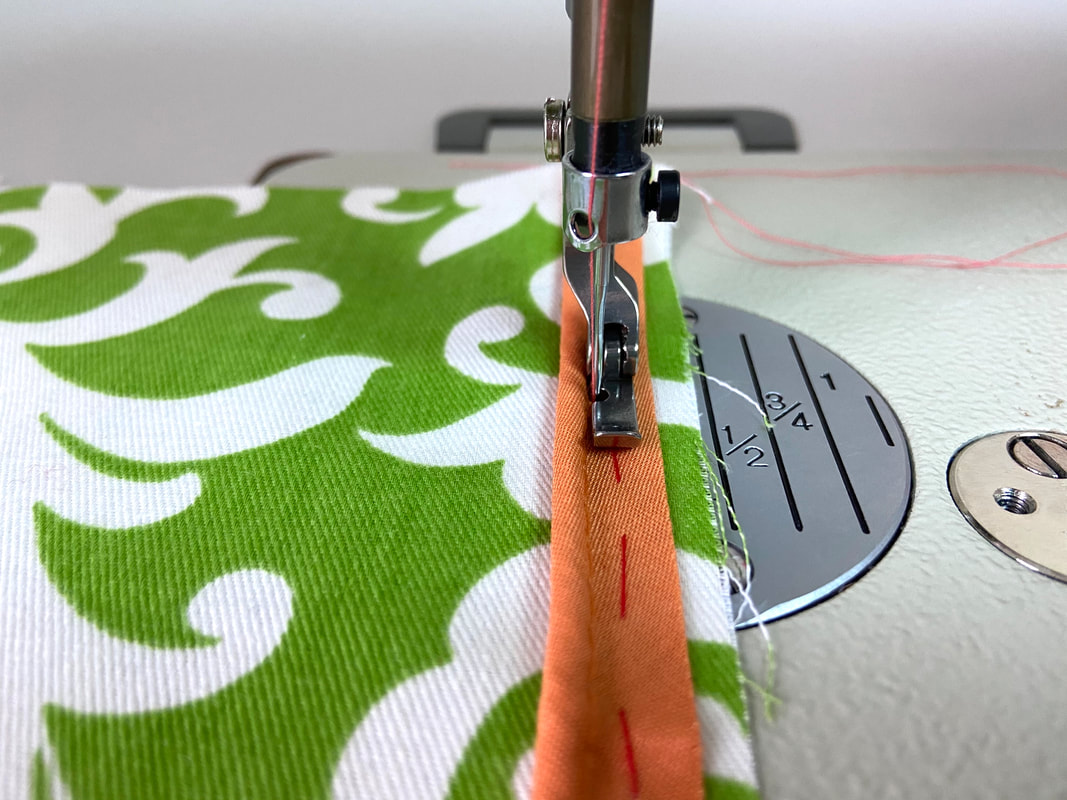

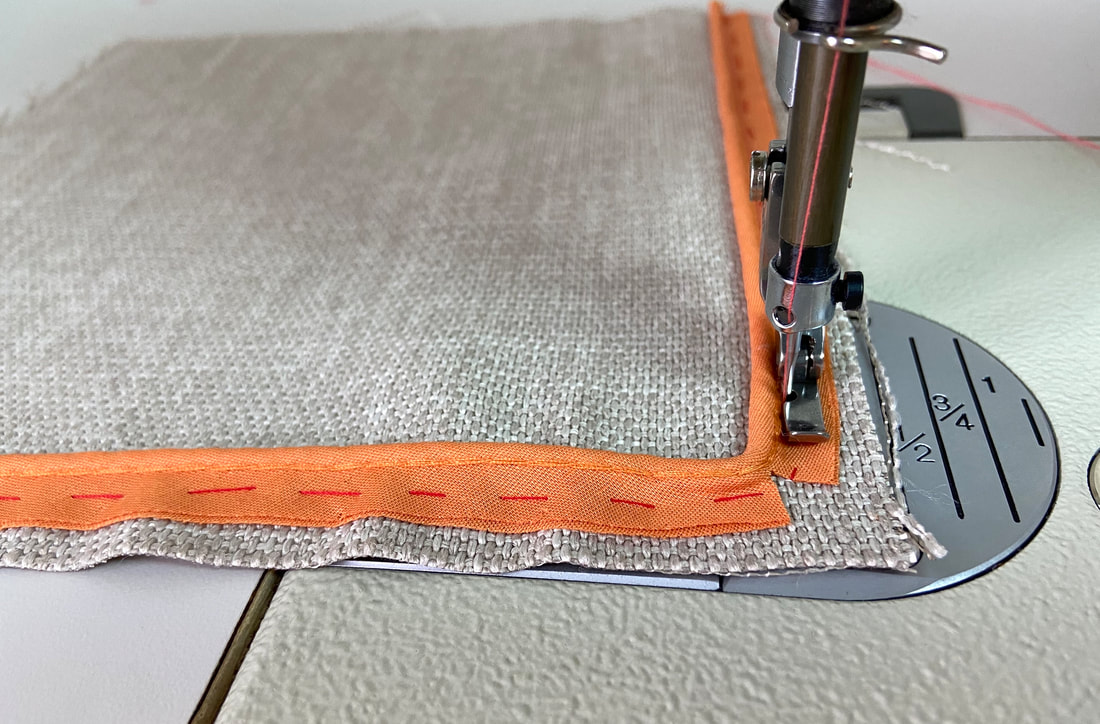

4. Align the needle to the left of the presser foot such that it aligns next to the raised edge of the cording. Stitch through the cording tape and fabric edge underneath following the existing stitch on the cording tape as a guide. This should feel quite natural since the raised cording edge leads the position of the needle as you stitch.

5. Once stitched, remove the basting using a seam ripper.

6. Next, align the other seam edge on top of the corded edge with face sides touching and the cording sandwiched in between the two layers as shown. Insert a few pins perpendicularly to keep all edges together.

Hand baste through all three layers for added stability.

7. Position the machine needle right next to the cording such that the fabric edges align with your machine’s seam allowance guides. Stitch to the left of the initial stitch applied in Step 4, being careful not to catch the actual cord underneath. Stitching to the left of the first stitch encloses all the preexisting stitches on the inside of the seam providing a professional, clean look.

Once complete, the corded seam should not have any visible machine stitching along its base.

8. The seam allowance on corded seams is almost always ironed in a single direction or encased by the two fabric layers as shown above.

To eliminate unnecessary bulk in the seam, you may also need to trim the cording tape.

If the seam allowance is pressed open, then a topstitch on either side of the seam will help keep the seam flat and the seam allowance edges permanently open.

How To Sew A Curved Corded Seam

A very common cording application is along enclosed curved and corner edges on quilting and home decorative projects.

If you attempt to mold cording tape around a curved edge, you’ll find that this is quite difficult to do. It is simply unnatural to mold a straight edge to a curved one.

The fix? Notching for tension release. When opposite shapes and curves are sewn together, notching increases the edges' flexibility and eliminates strain. Once notched, the edges can be easily aligned and stitched.

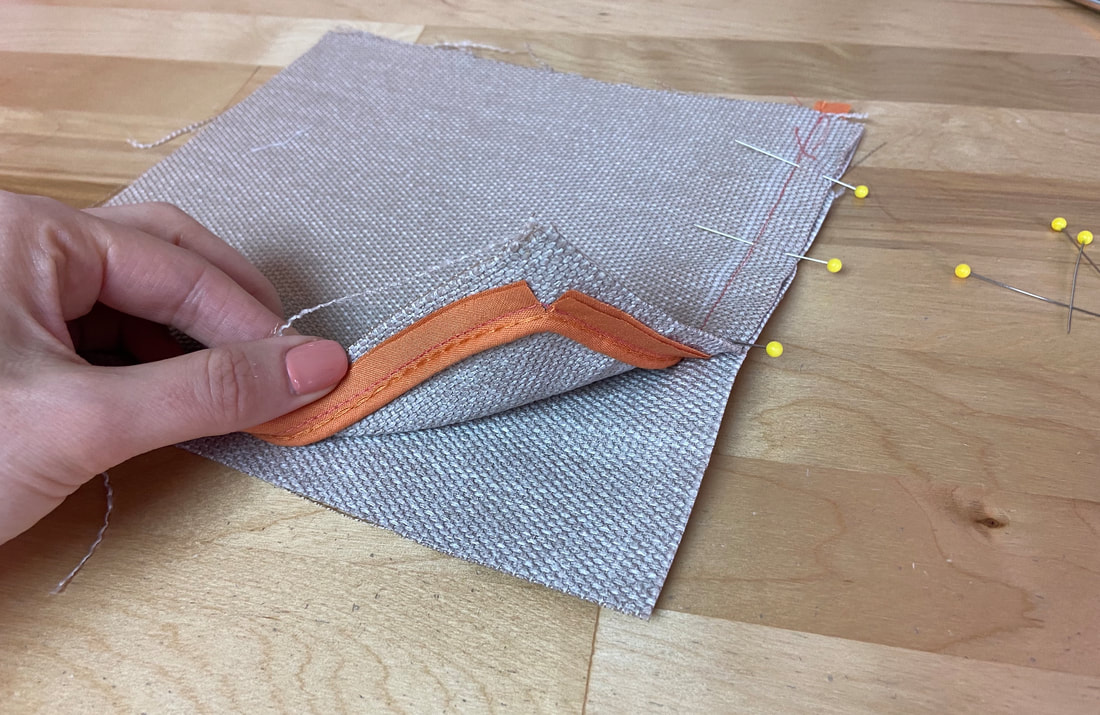

1. Pin the cording along the fabric edge as you would with any straight corded seam. When arriving at the curved area, clip the cording tape a few times up to the stitching but not through it.

The slashes will spread allowing the cording tape to be easily molded around the curved edge. Insert pins perpendicularly as you align the tape to the fabric edge.

2. Hand baste and stitch the cording tape to this curved seam edge using a regular zipper foot as described above.

3. Once complete, remove the temporary hand basting using a seam ripper.

4. Place the other corresponding seam edge on top of the corded edge such that the fabric face sides are touching and the cording is sandwiched in between. Insert pins and hand baste the curved seam in preparation for stitching.

5. Stitch through all three layers using a zipper foot. Use the stitching from Step 2 above as a guide. Be careful stitching around the most curved area- you will need to slow down or even walk the stitch in order to keep it smooth and even.

If you used hand basting to keep the layers secure, remove it at this point.

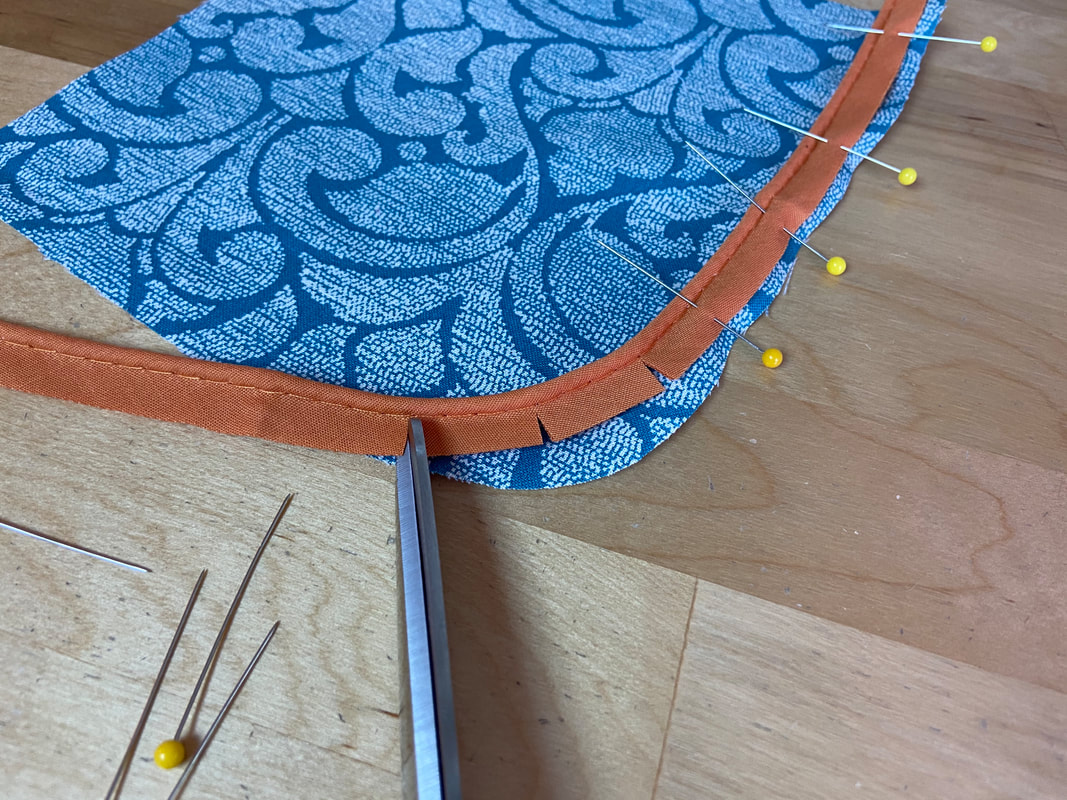

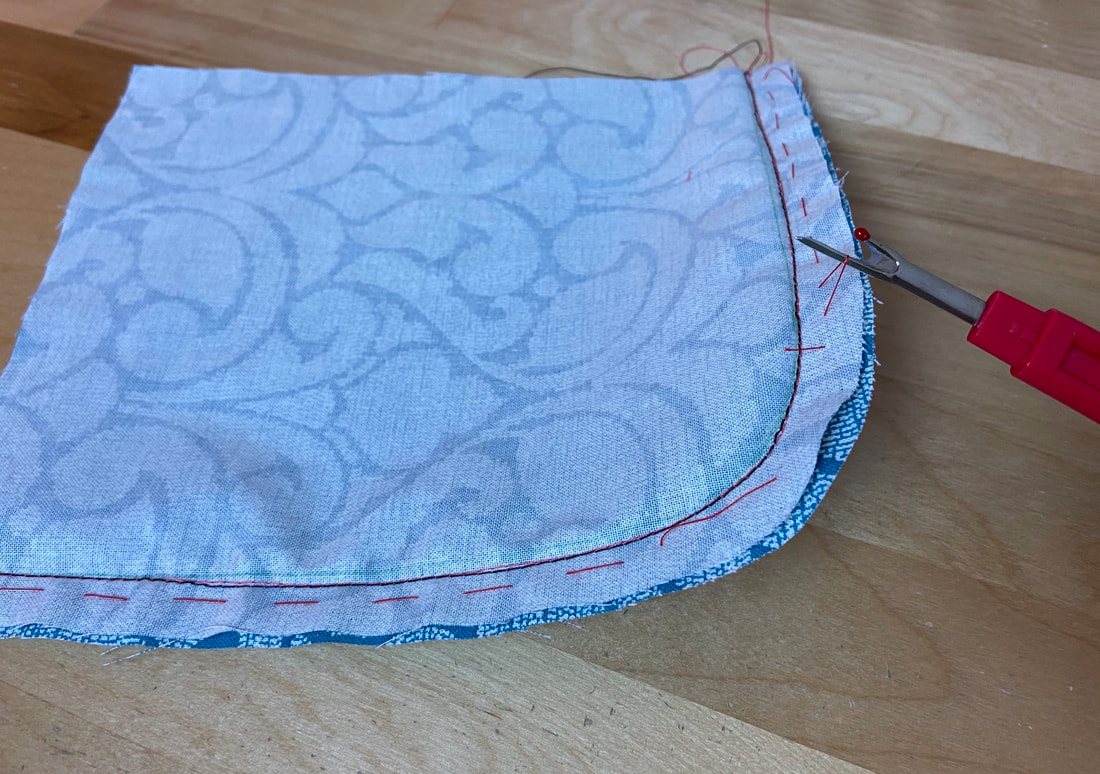

6. To minimize bulk, clip wedge notches along the curved area of the seam allowance as shown. If working with extra thick fabric, you may also trim the cording tape in between the two seam allowance layers down to about ¼”.

As a final step, iron the finished cording application.

How To Sew A Corded Corner Seam

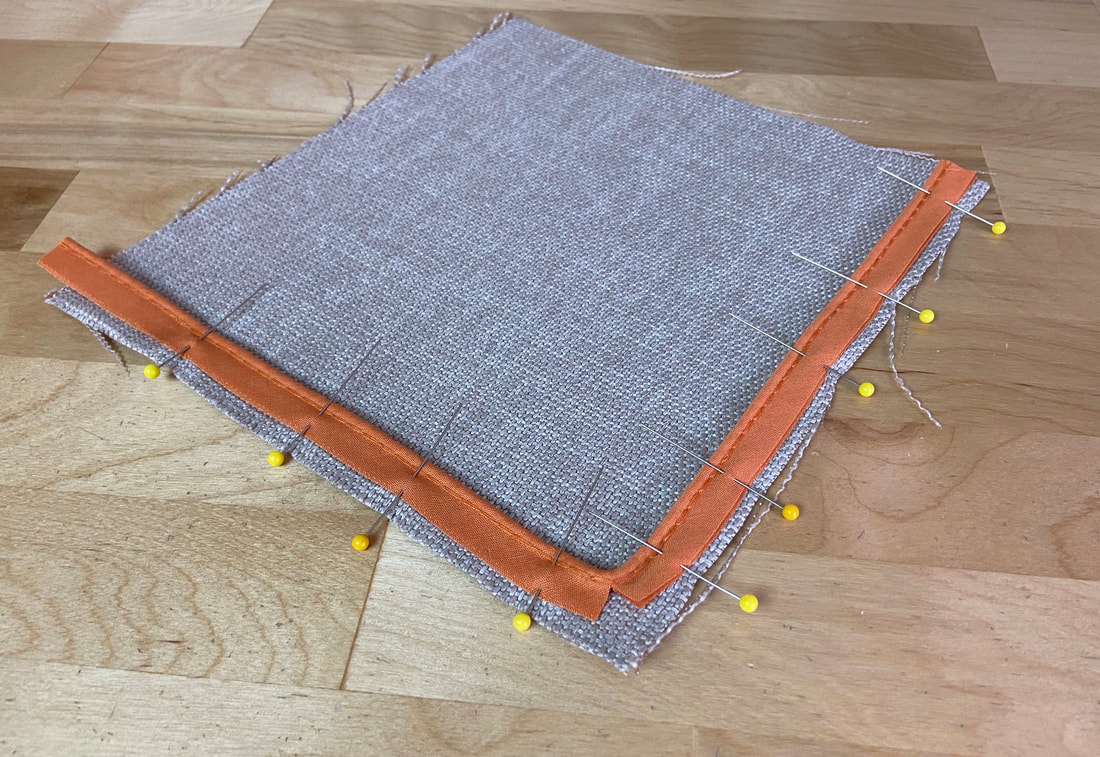

1. When sewing a corded corner seam, follow the same process described above. However, when you arrive at the corner, clip the cording tape just once right at the point where the cording aligns with the fabric corner.

2. Pin and hand baste the cording tape to the corner seam edge.

3. Machine stitch the cording to the fabric edge.

4. When arriving at the corner, leave the needle inserted, lift the presser foot and shift the direction of the edge such that the bottom horizontal edge is now aligned to the seam allowance guides. Drop the presser foot and continue stitching.

5. Remove any hand basting at this point.

6. Align the other corner seam edge on top of the corded one such that the face sides are touching. Pin and hand baste all layers together prior to machine stitching.

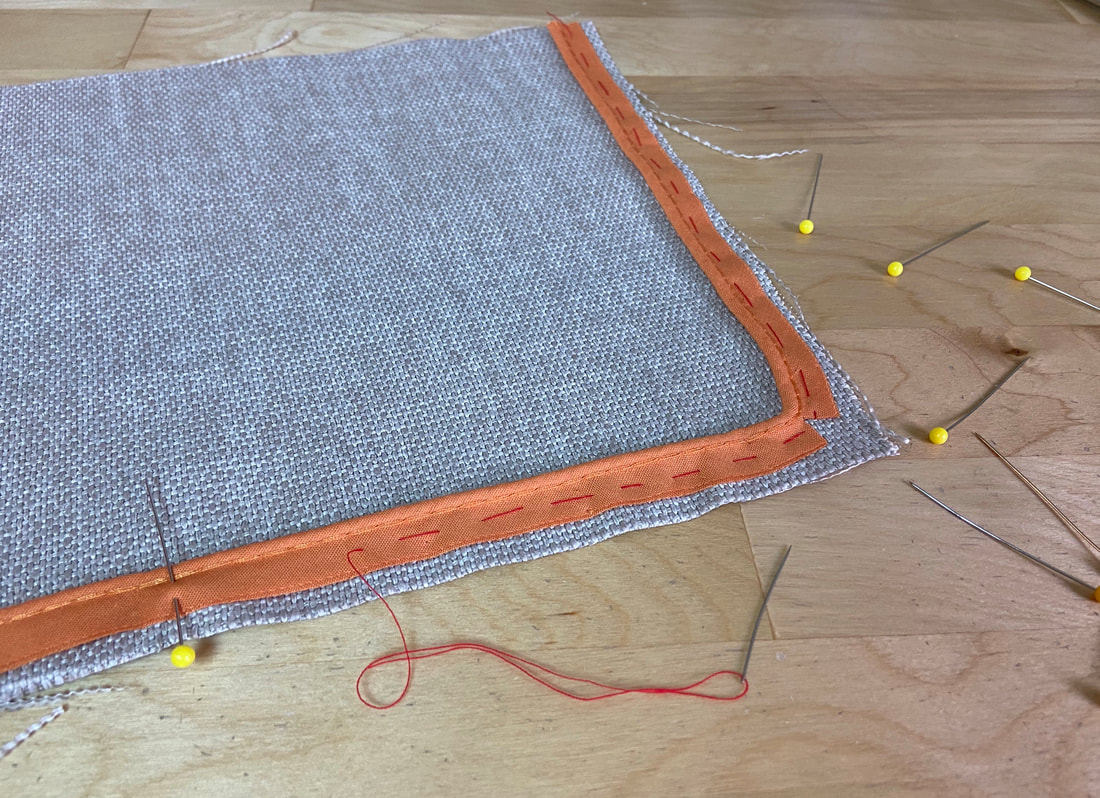

7. Again, carefully stitch right next to the cording following the existing stitch line (from above) as a guide.

8. Remove any hand basting at this point. Trim the corner seam allowance diagonally to eliminate bulk and remove excess fabric.

9. Iron the enclosed corner edge from the face of the cording application.