As opposed to most conventional armhole finishes, such as binding and facings, a decorative trim is used to visually enhance and add a more professional look to armscye edges. A decorative armhole finish cannot be applied to just any garment. Fabric is the main determining factor as to whether a decorative finish is suitable or even attainable.

In most cases, using a decorative trim as an armhole finish entails that the edge is left completely unfinished and simply hidden underneath the trim. This means that the fabric should naturally not fray or unravel (even slightly) when cut.

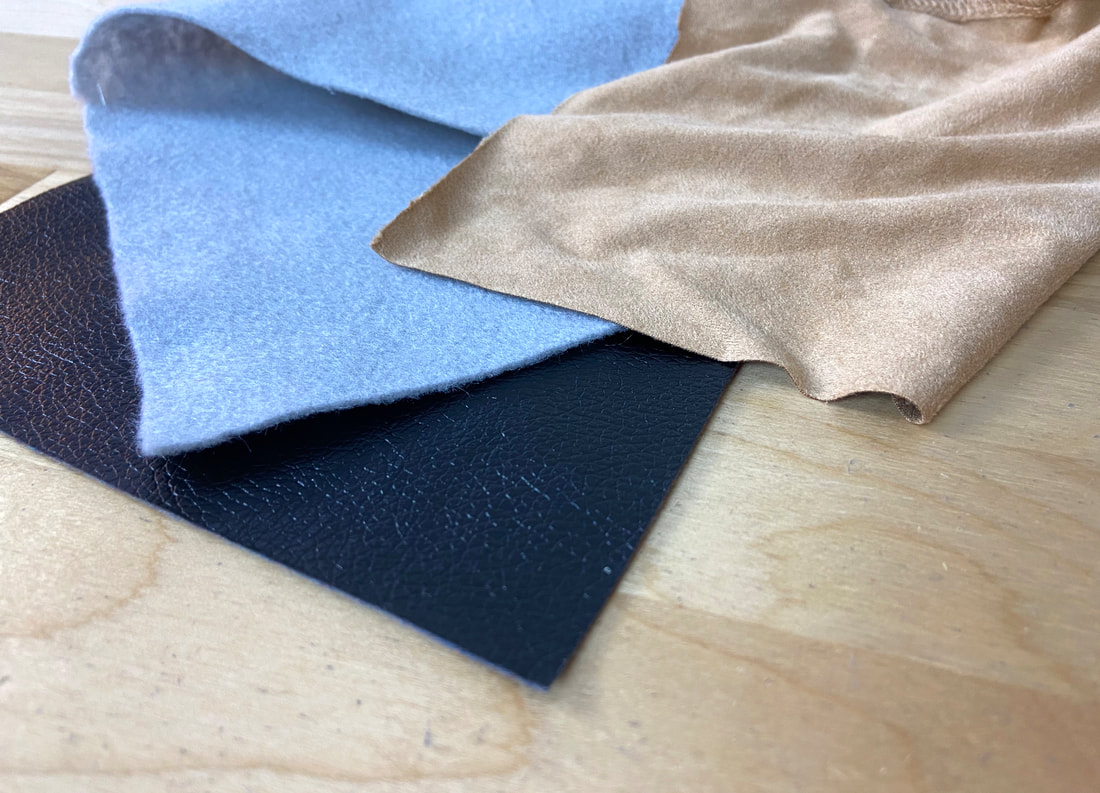

The most suitable fabrics for a decorative trim finish are structured, no-fray materials like leather, vinyl, suede, etc. These do not unravel when cut and thus the armhole edge can be left untreated. Since these fabrics are trickier to stitch and clean finish in a conventional fashion, a decorative trim is often the best option. Even though they don’t fray, the trim is used to hide these cut edges for a more professional, finished design.

In some cases, you can use a decorative trim to finish an armhole if the fabric’s fraying can be efficiently contained with an overedge stitch like zigzag or serging. In this case, the overedge stitch is applied along the cut armhole edge to give it an extra layer of security before applying the trim.

For this technique, the armhole requires no seam allowance. The trim should be suitable for the weight and style of the fabric at hand.

Speaking of decorative trim choices, use your design eye to find the one most suitable for your fabric and the garment’s design. While looks are important, the level of difficulty in sewing the trim, as well as how efficiently it hides the armhole edge, are also important to consider.

Decorative trims can be hand sewn or machine stitched depending on the type of trim and how heavily decorative is. If you’d rather not hand stitch your trim, be sure to choose one that is safe to machine stitch.

Keep in mind that your choice of trim should also have enough body and density to securely cover the armhole’s cut edge. For that reason, the trim’s lengthwise edges are also important to consider.

A plain, straight or semi-straight trim edge is perhaps most suitable and easiest to work with.

Sewing Decorative Trim To A Closed Armhole Edge

Before applying the trim, make sure both garment shoulder seams and side seams are stitched, finished and ironed as indicated.

The armhole edges should have no seam allowance. In other words, the armhole’s cut edge corresponds to the finished armhole edge.

If working with no-fray fabrics like crips knits, suede, leather/pleather, and vinyl:

1. Prior to stitching the trim, add a staystitch along the entire armhole edge at about 1/8” away from the cut edge. For extra stability, add two straight stitches side by side.

The armholes receive a lot of movement and strain during wear, thus the addition of staystitching maximize durability and prevents the armhole edges from stretching over time.

If working with semi-fraying, low-structure fabrics:

In addition to the staystitching, finish the cut edge of each armhole with an overedge stitch. This can be a dense zizag stitch, a hand-applied blanket stitch, or a serging stitch (if you have an overlock machine).

Before alignment, decide whether you’d like the trim to hang off the edge of the armhole or mostly cover its surface.

If you choose to have the trim protruding outwards, make sure to overlap the trim at least ¼” within the armhole edge to provide enough space for stitching.

2. With the garment on its right side, align and pin one end of the trim about ¼” past the garment side seam at the underarm as shown.

3. Continue aligning and pinning the trim in the desired placement, positioning it evenly throughout the entire armhole edge.

4. When arriving at the garment side seam, overlap the trim’s starting point, and cut the excess trim at about ½” past the garment seamline as shown.

5. Fold the end of the trim such that the folded edge is in line with the garment seam as shown.

If your trim is bulky, you can fold both edges in at the seamline as shown above.

6. Once the trim is aligned and held in place by pins, hand baste it to the armhole edge for extra stability during machine stitching. Trims have a tendency to shift in the stitching process thus adding a temporary hand basting stitch adds a layer of security and comfort during machine stitching.

7. If your trim can be attached by machine, stitch it to the armhole edge from the face of the garment as shown.

Due to the oval shape of the armhole, machine stitching may feel a little uncomfortable since you’ll have to continue to shift the edge in a more comfortable position as you stitch- hand basting keeps the trim securely aligned during this process.

8. Using a seam ripper, remove the hand basting once stitched.

In terms of where to stitch on the trim itself, look for a woven-in stitching guideline or choose the area that will provide the most secure connection without affecting the look of the finished trim.

9. If your trim cannot be machine stitched, use a blind stitch to attach the edge of the trim to the armhole area. You can also use a prickstitch (used here) to discreetly sew through the body of the trim and garment layer underneath.

10. As a final step, blind stitch the folded end (starting point) of the trim to the layer it overlaps.