A bias strip neck finish, also called a bias facing, is perhaps one of the easiest of all neckline applications. This technique is perfect for softly curved edges. While simple in its construction process, it does require a bit of hand stitching.

In this application, the neckline edge is finished with a fabric strip that is cut on the bias for extra stretch. The bias cut allows the strip to easily shape around curved neck edges.

In the application process, the bias strip is folded onto itself to provide a clean-finished outer edge. When in folded position, the two lengthwise raw edges meet and are sewn to the neckline edge. All raw edges are then enclosed by the body of the bias strip.

Since the bias strip requires folding, it should be cut at double the width, plus two seam allowances to account for stitching the bias edges to the neckline edge.

For example, a bias finish that is ½” wide when completed and is sewn into a neckline edge that has ½” seam allowance, should start with a bias fabric strip that is 2” wide (1” for the body of the bias and 1” to account for two ½” seam allowances when the strip is folded onto itself). Follow the same logic using the width of your neckline’s specific seam allowance and how wide you want the final bias application to be.

A final bias facing application can range anywhere from ½” to 1” in width. If it exceeds 1”, the bias strip will lose its flexibility and may not mold as well around curved edges.

In terms of fabric, a bias neck facing can be cut from the same fabric (but cut diagonally on the bias), or from a lighter-weight fabric. The latter is especially helpful when the garment is made of thick, bulky material.

Speaking of fabric, not all fabrics are suitable with a bias facing finish. Ironically, a bias strip neckline is either used with lightweight, sheer fabrics or garments sewn from heavy, bulky fabrics.

Sheers are not compatible with conventional facings since the underside of the facing is visible on the face of the finished garment. A folded bias strip provides a clean, less visible alternative, providing a professional finish both on the face and wrong side of the garment.

Conversely, a bias neck facing works well for heavy garments for which a conventional facing would add too much bulk. In this case, using a bias strip that is sturdy enough to keep the neckline edges down but thin enough as to not add excess bulk, serves as the perfect neck finish.

A bias facing is also a great alternative for bias binding, or when a visible topstitch is not desired on the face of the garment.

Finishing The Neckline Edge With Bias Facing

1. Determine the width of the finished bias strip. Do not exceed 1”.

In this example, the finished bias facing will be ½” and be sewn into a neckline edge that has ½” seam allowance. Doing the math, the total width of the bias fabric strip to be cut is 2” - seam allowance plus bias facing width x 2.

To cut the bias strip (s):

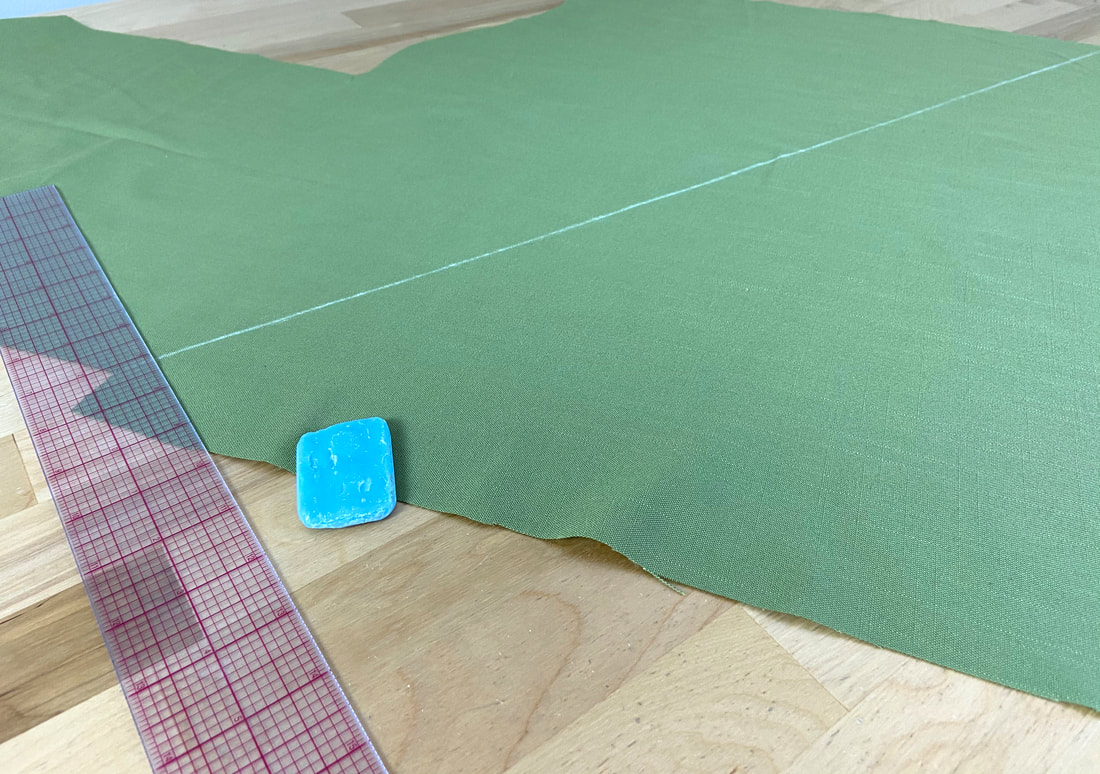

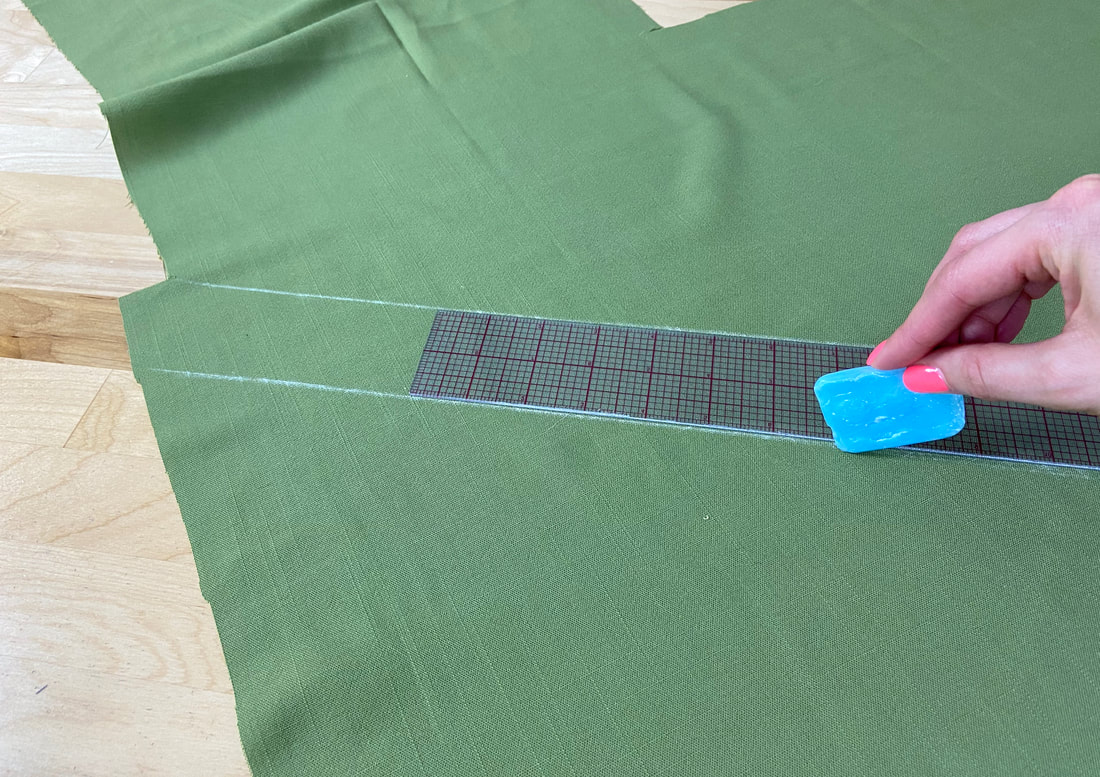

2. Lay the fabric flat on the table and fold the fabric such that its crosswise edge is parallel to the selvage. The fold line created as a result depicts the fabric's bias. Mark down this fold line with tailor’s chalk as shown above.

3. Next, using a ruler (preferably a marked clear plastic ruler like the one used in this tutorial), draw a parallel line with tailor’s chalk above the first bias line. The distance between the two lines should be 2”. This will mark the initial bias strip.

If your final bias facing will need to be longer than this initial bias strip, mark additional 2-inch intervals from the second line. These separate pieces are cut individually and can be sewn together to create a continuous bias strip.

4. To determine the length of the bias strip needed (if not already provided), use a measuring tape to measure around the edge of the neckline and add 2-3” to this measurement. This final number will determine how long the bias strip needs to be for this particular neck finish.

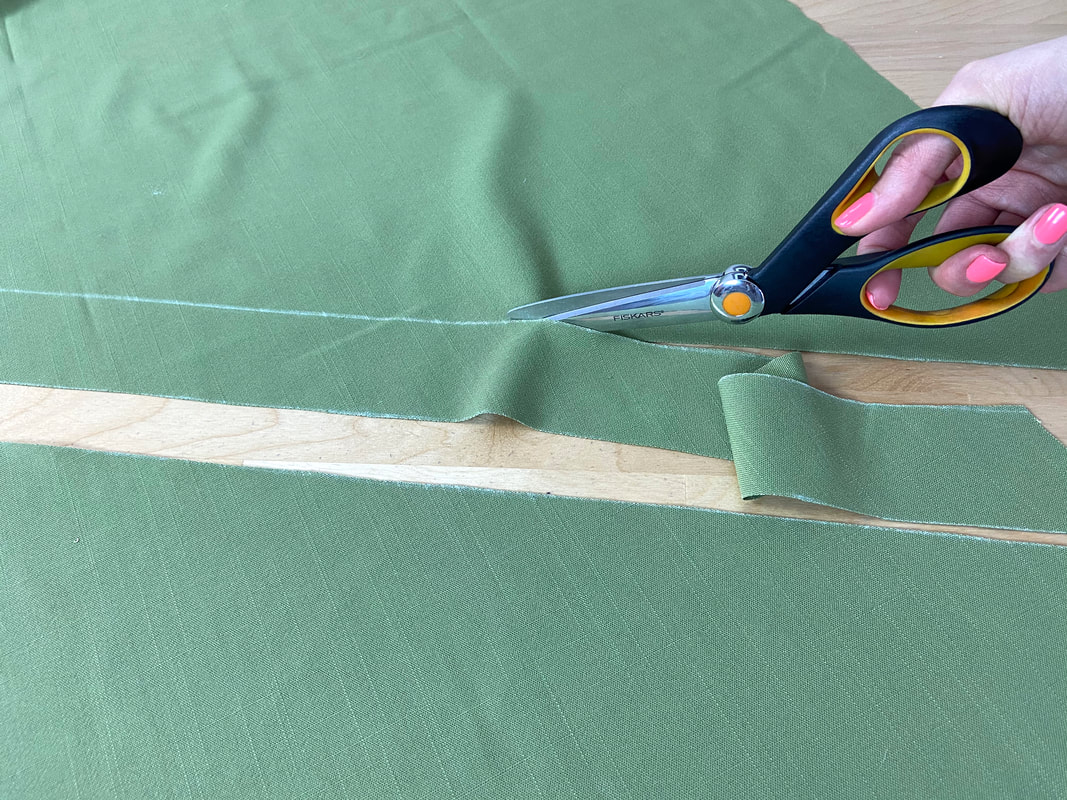

5. Carefully cut along each tailor’s chalk line. If multiple pieces need to be sewn together, do it at this point.

Use the steps in this tutorial to sew the individual bias strips together: How To Sew Continuous Bias Binding

To attach the bias facing to the neckline:

7. Fold the bias fabric strip lengthwise down the middle such that the fabric wrong sides are touching and the lengthwise raw edges are perfectly aligned.

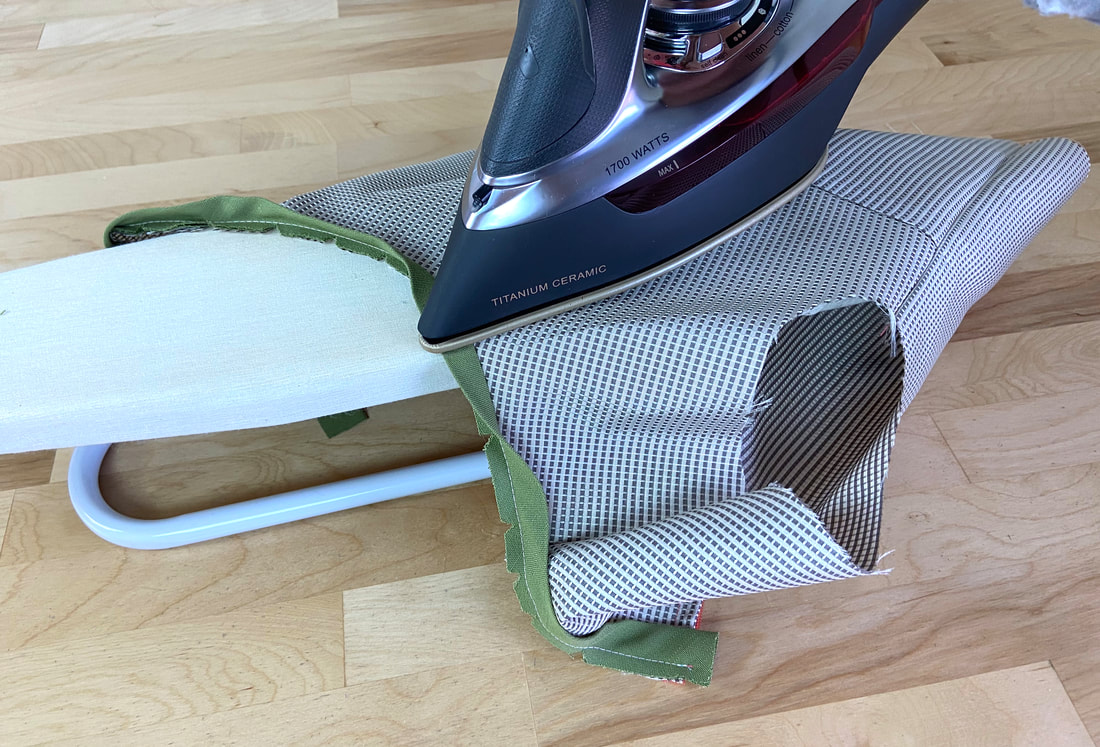

Iron the folded bias strip to crease the folded line.

8. As you iron, stretch the bias gently such that it starts to resemble more of a curved shape. Doing this at the ironing stage, shapes the bias facing such that it is easier to align, mold and stitch to the neckline’s curved edge.

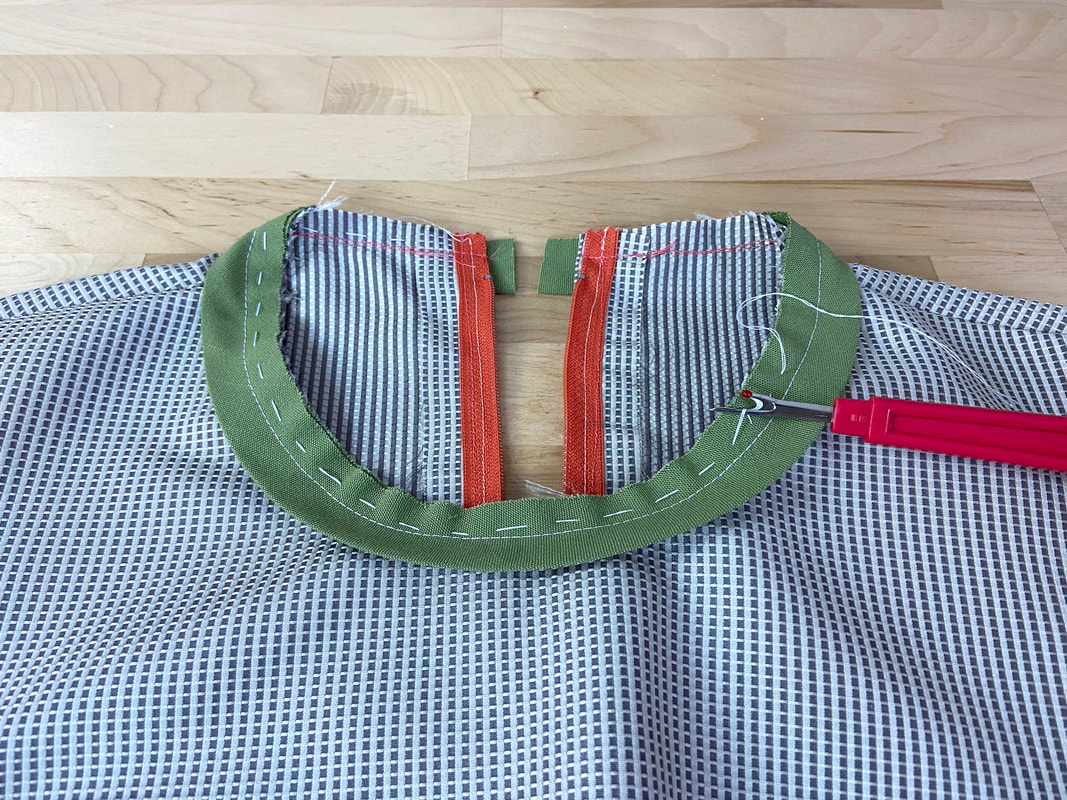

At this point, make sure that the shoulder seams and any zipper closure(s) have been fully sewn and finished before proceeding with attaching the bias facing.

In this case, the center back zipper has been inserted and the shoulder seams have been stitched, ironed and finished with a serged overedge stitch.

9. Open the zipper, and leaving about 1/2” of excess, align the bias facing to the neckline edge from the right side of the garment as shown.

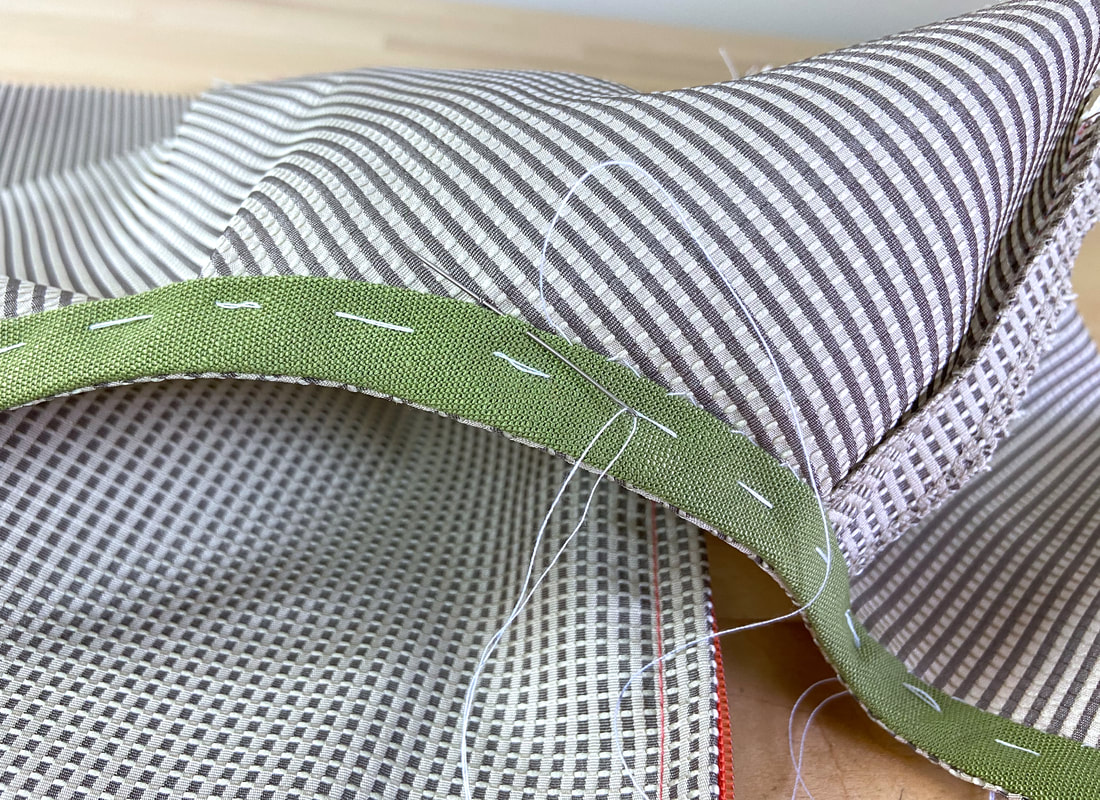

Insert pins perpendicular to the edge as you align the neck and bias edges. Start at one of the zipper’s opening edges and move all the way around the front and back neckline until you arrive at the other zipper opening portion. Keep in mind that all edges have to match up perfectly.

Pay close attention to the folded bias edges, ensuring that they do not slip away from each other in the alignment and pinning process.

It may actually be helpful to stitch them together prior to attaching them to the neckline edge, especially if the bias facing is constructed of slippery, thin fabric.

10. Leave another 1/2” of the bias strip excess at the end, just as you did at the beginning and trim the excess bias strip.

11. To facilitate the stitching process, it is a good idea to hand baste all layers together next to the seamline (stay within the seam allowance) prior to machine stitching.

12. Starting on one end of the zipper opening, begin stitching carefully, following the designated seam allowance (1/2” in this case). Keep the curved stitchline smooth and even throughout. Stitch until you arrive at the other end of the zipper opening.

13. Once the stitch is applied, remove the hand basting with a seam ripper.

14. Trim the seam allowance down to half the width.

Note: You may need to grade the seam allowance by cutting the bias facing seam allowance shorter than the one corresponding to the garment.

Note: You may need to grade the seam allowance by cutting the bias facing seam allowance shorter than the one corresponding to the garment.

15. Next, clip wedge notches into the neck seam allowance to release tension and minimize bulk.

16. Keeping the bias facing and its seam allowances pointing away from the garment, iron the finished neckline seam. It is easiest to iron from the face of the garment as shown.

17. Next, fold the bias facing to the inside of the garment in its finished position, and press the finished neckline edge. Insert pins perpendicular to the edge to keep the bias facing down.

18. At each zipper end, fold and pin the bias strip ends in (as shown above), before positioning the facing down against the garment.

Consider hand basting the folded bias strip flat if working with slippery, flimsy fabrics- this is completely up to you and your comfort level.

19. Last but not least, slipstitch the folded edge of the bias facing to the wrong side of the garment. Don’t pull too much on the stitch, keeping it as even and “invisible” as possible.

To learn how to slipstitch, follow the steps in this tutorial: Hand-Applied Blind Stitches

20. Don’t forget to also slipstitch the facing vertically at each zipper end.

21. Once complete, remove the hand basting using a seam ripper.

22. Last but not least, give the finished neckline one last press to complete the application. As always, use a protective cotton cloth if working with a heat sensitive fabric.