What Is Interfacing And Types Of Interfacing You Should Know

Interfacing is a woven or webbed material that is attached or fused to the wrong side of a fabric layer to give it extra structure and thickness.

Interfacing is different than regular fabric in the fact that it is used to back other fabrics but is not durable enough to stand on its own.

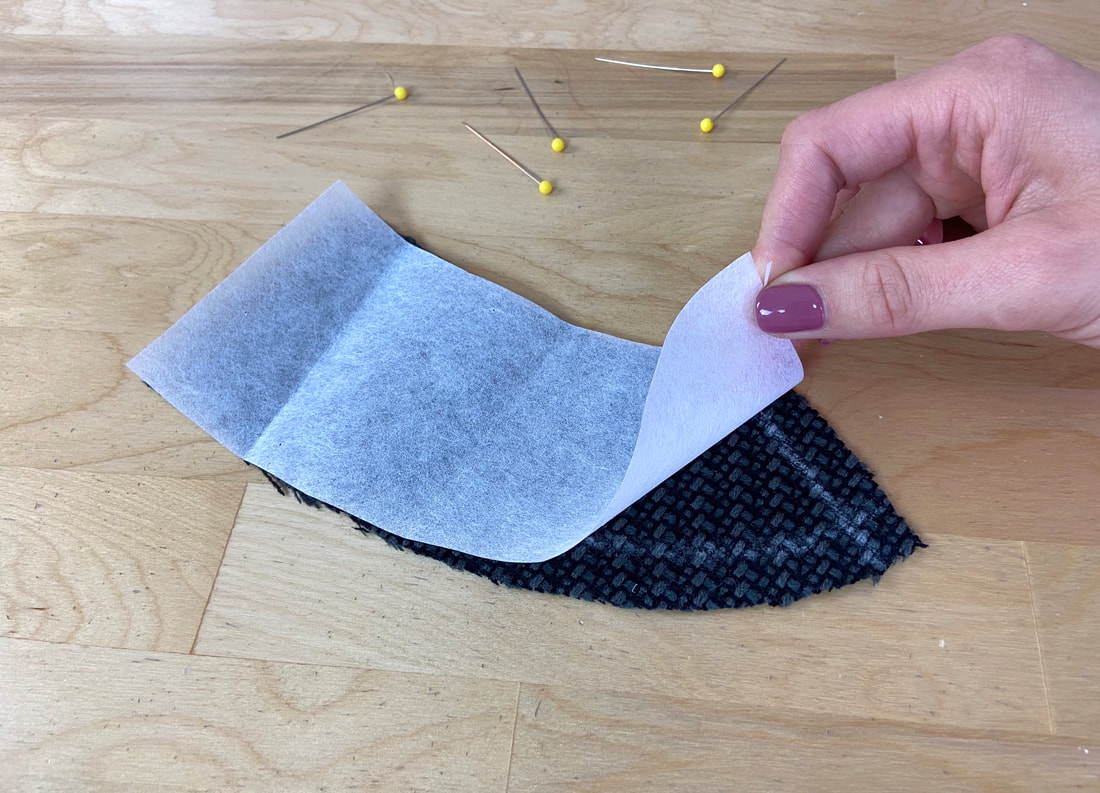

Most interfacing fabrics are constructed of a polyester fiber webbing which can be either fused with a hot iron, or sewn by hand or machine. While this webbing structure is the least expensive and most commonly used, interfacing is also available in stretch knit and woven structures. These fabrics are coated with adhesive glue on one side for heat bonding.

Generally, interfacing can be divided in two large groups: fusible interfacing and sew-on interfacing.

Fusible interfacing is adhered to the fabric surface by heat bonding with an iron.

Sew-on interfacing is stitched to the wrong side of the fabric either by hand using a slipsticth/catchstitch, or by machine with a regular straight stitch.

Regardless of whether it is fusible or sew-on, interfacing is available in a variety of weights, thicknesses and densities. Choosing the correct weight and thickness to match the garment’s fabric and design is imperative for constructing a high-quality garment.

Interfacing should add structure and stability where the garment needs it, but not affect the desired drape and movement in the overall design. When choosing your interfacing, the first thing to consider is whether to use the fusible or sew-on option.

Fusible interfacing is conventionally a first choice as it is very easy to attach and work with. However, if you find that your fabric does not adhere well to fusible interfacing (always good to test a scrap) or the fusible does not provide enough structure, sew-on interfacing may be a better choice. The steps for attaching both fusible and sew-on interfacing are outlined below.

Another aspect to consider is the garment’s long-term care. The care instructions that come with the interfacing should be as close as possible to the recommended care on the final garment.

Although fusible interfacing is, for the most part, built to withstand machine washing, if the fabric does not adhere well to the interfacing or the wash cycle provides too much friction, the interfacing layer will peel off in the wash.

If unsure, test a scrap of the fabric with your choice of fusible interfacing by machine washing it after it has been fused. If the fusible interfacing disintegrates with too much friction but you prefer to continue using it for your project, hand wash the finished garment instead of machine washing it.

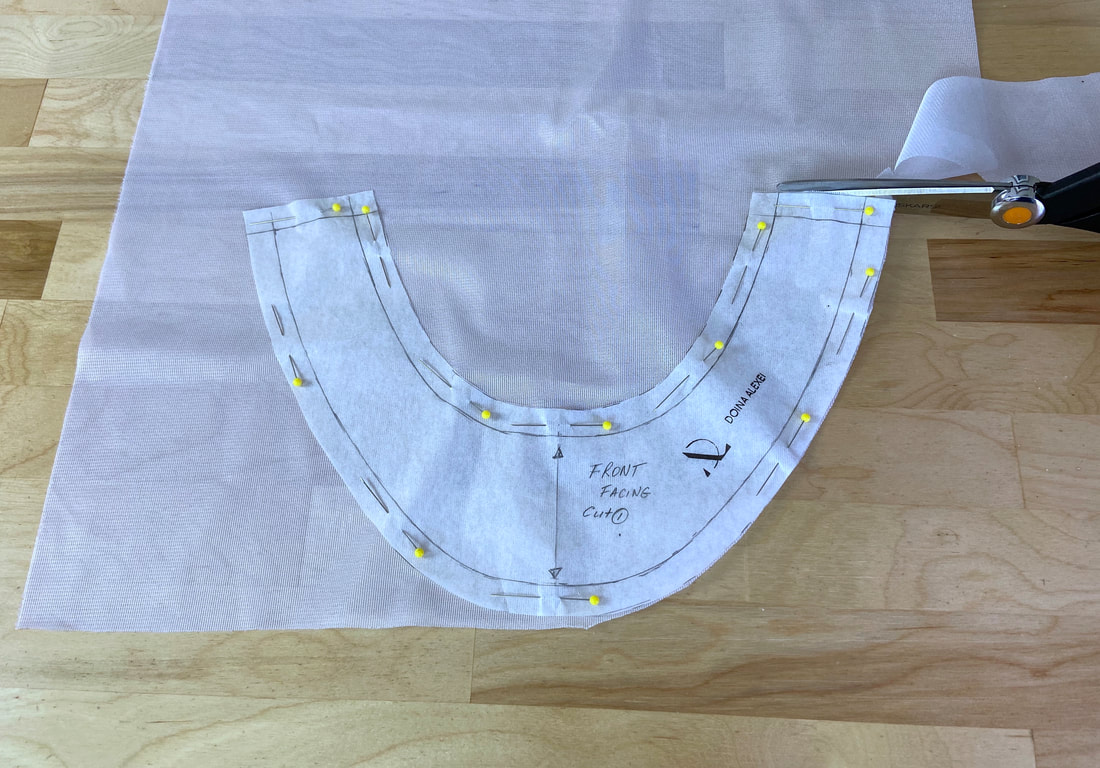

If you are working with a store-bought pattern set, the instructions should indicate which areas should be interfaced. In some cases, separate patterns are provided for the interfacing pieces. If not provided, you can use matching pattern pieces to cut the interfacing portions. This is often the case with conventional facings.

Don’t use interfacing with sheer fabric as it will show on the face of the garment. Interfacing should be completely hidden both on inside and outside of the garment.

How To Attach Fusible Interfacing

1. If separate patterns are not provided, cut the fusible interfacing piece using the pattern of the garment portion the interfacing will back. When you cut the interfacing, the adhesive side should correspond to the wrong side of the fabric layer. You may need to do some testing to make sure this is so before cutting the interfacing.

In this case, a neck facing is interfaced.

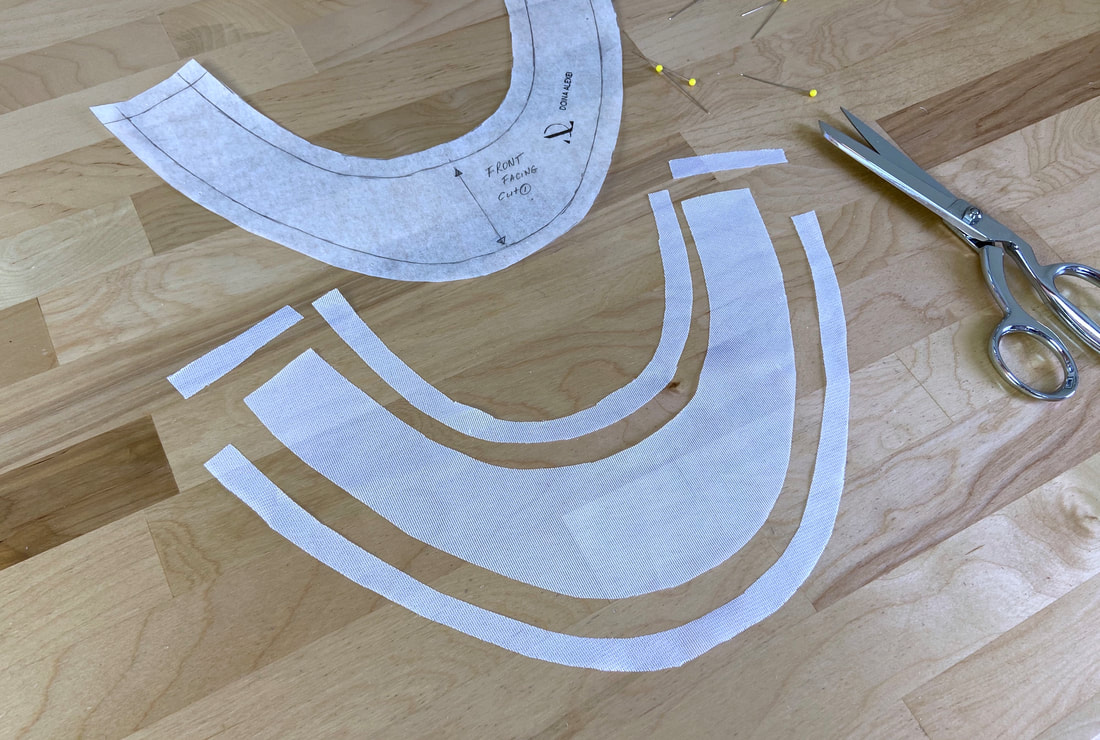

2. Once the interfacing is cut, trim the seam allowance along all edges. Doing so will minimize bulk in the finished garment.

3. Place the interfacing on the wrong side of the facing layer, centering it within the seamlines as shown.

4. Heat the iron to the highest setting compatible with the garment’s fabric. Place a cotton cloth over the interfacing, being careful not to shift it out of place in the process. This cloth is extremely important in the application process as it will protect your iron plate from the fusible interfacing’s adhesive.

5. Starting at one end, press the iron against the cloth and interfacing underneath. Hold the iron in place for a few seconds to bond the interfacing. Continue along the entire portion of the interfacing until it is fully bonded with the fabric layer. Don’t slide the iron across the interfacing until after it has been fully adhered to the fabric.

The end result should be a smooth, fully-connected interfacing that adds just the right amount of structure to the garment.

How To Attach Sew-On Interfacing

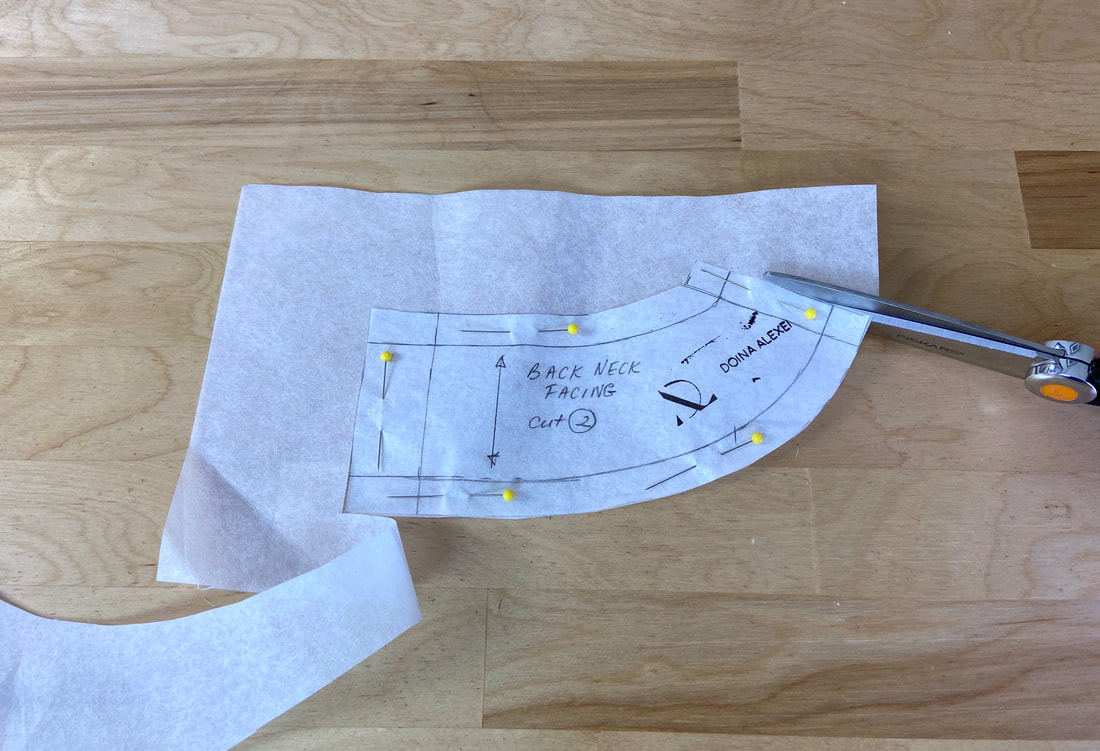

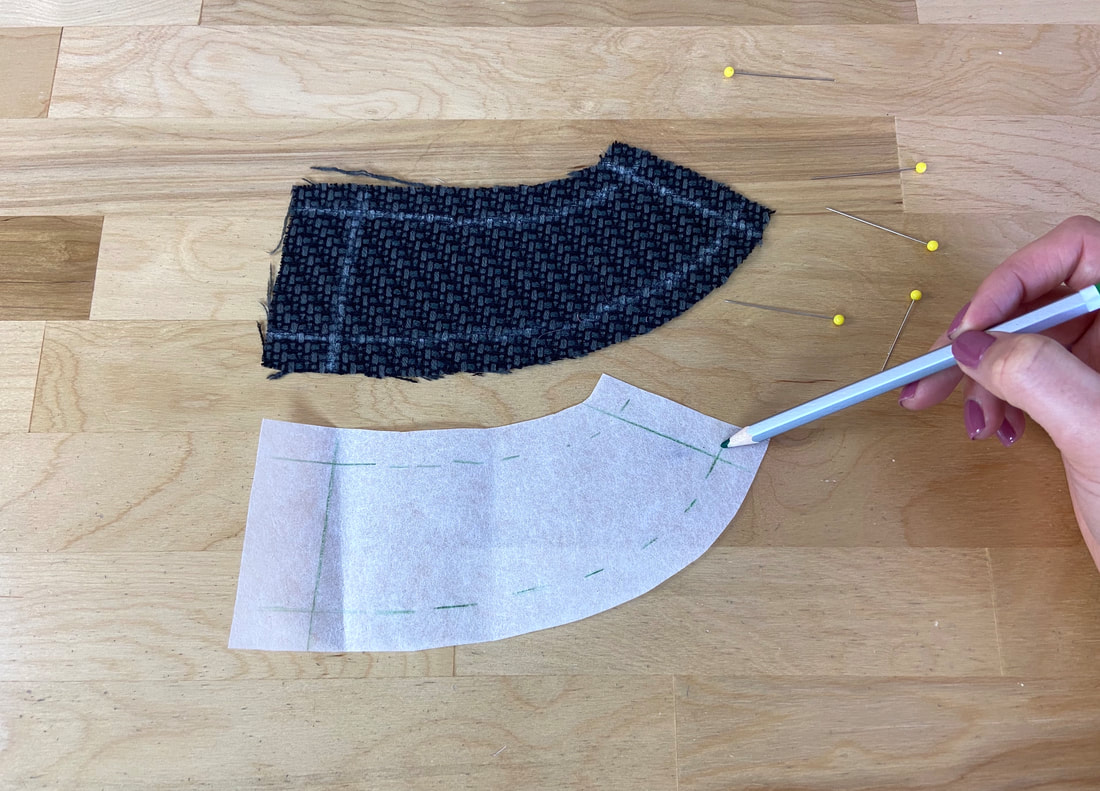

1. Cut the interfacing piece using the pattern of the garment portion being interfaced. A neck facing is interfaced in this case.

To facilitate the attachment process, transfer all seamlines to the interfacing layer using a fabric pencil. The beauty of sew-on interfacing is that there is no wrong and right side to worry about

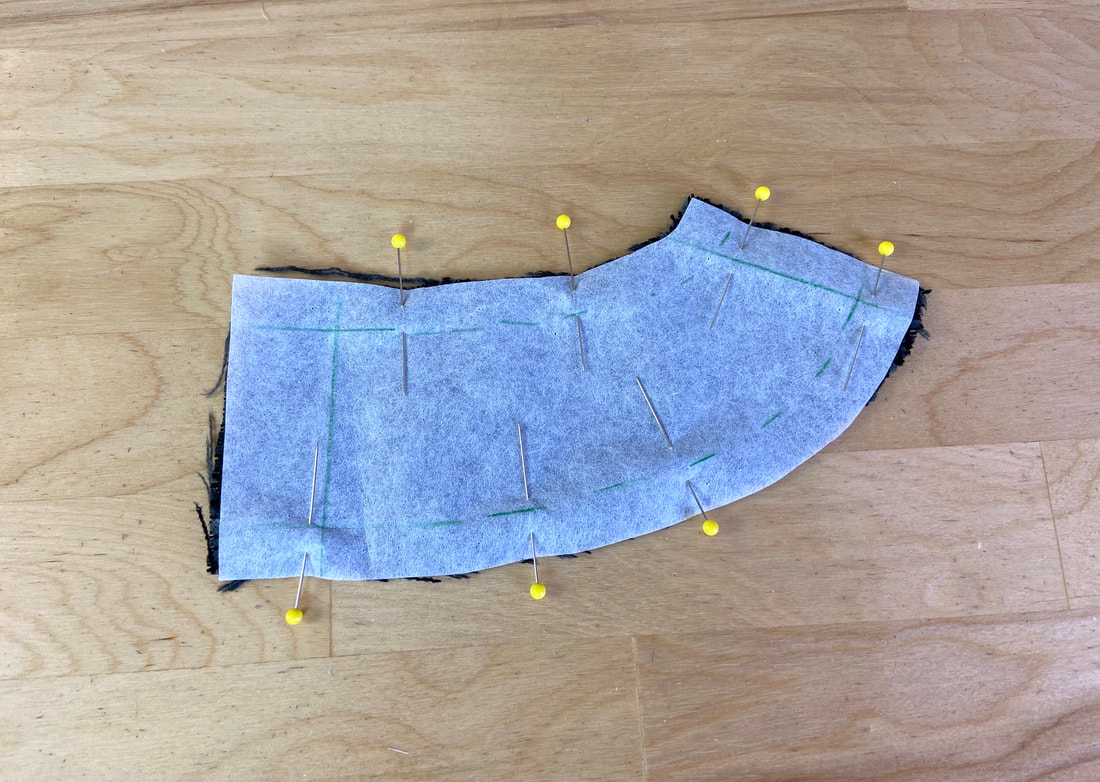

2. Pin the sew-on interfacing to the wrong side of its corresponding garment piece with the marked seamlines facing up. Pin perpendicular to the edge as shown.

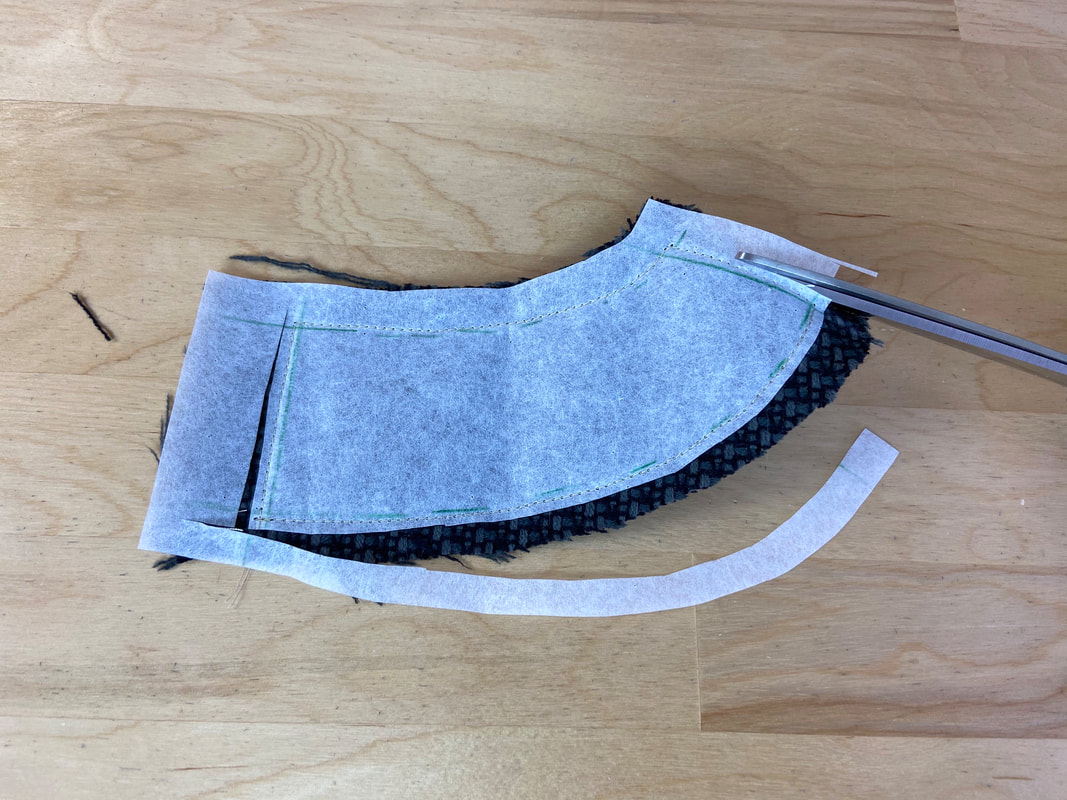

3. With the interfacing facing up, stitch it to the fabric layer next to the seamline, within the seam allowance as shown.

4. To complete the application, carefully trim the interfacing seam allowance excess next to the machine stitch.

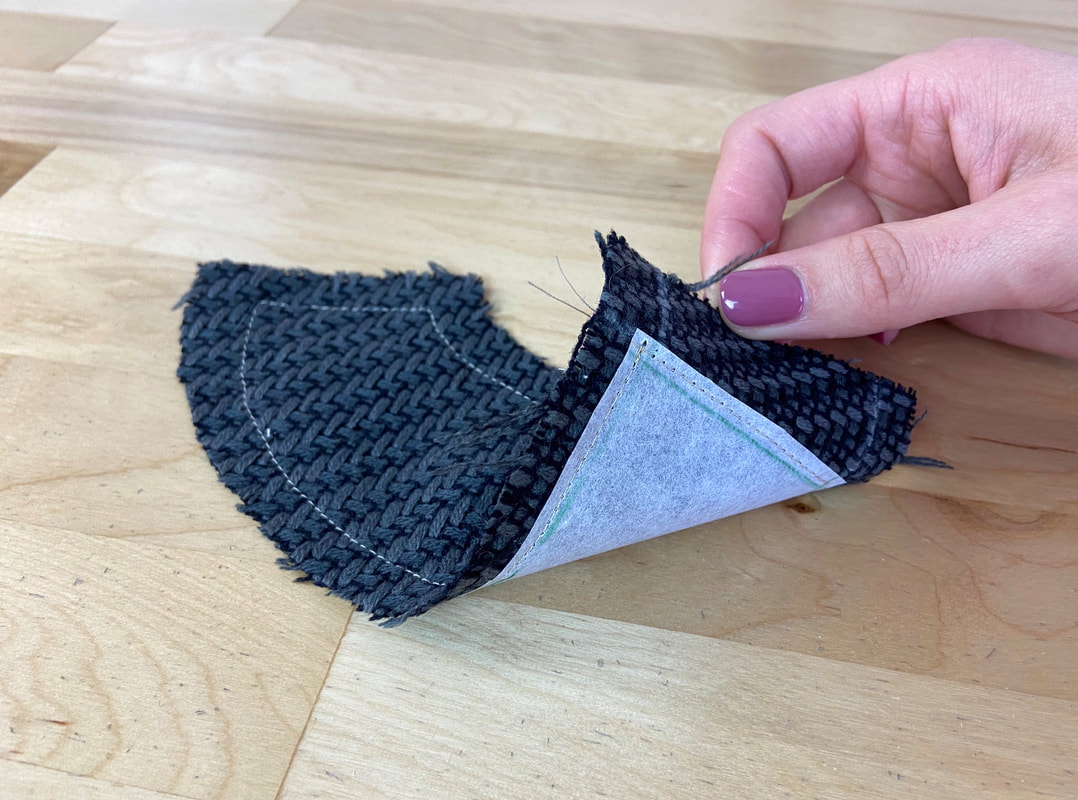

If the sew on interfacing is added directly to the garment layer (instead of the facing), the interfacing will have to be attached by hand using a blind stitch as shown. In this case, no stitching should be visible on the right side of the garment.

More on blind stitching, and how to slipstitch by hand is covered in this tutorial: Hand-Applied Blind Stitches