What Is An Exposed Separating Zipper Application

An exposed separating zipper is perhaps one of the most common zipper applications in dressmaking. It is often used in outerwear, casual and active wear, as a conventional front opening on jackets, cardigans, sweatshirts and other similar items.

An exposed separating zipper can be made of plastic coils, which is used with lighter-weight styles, or metal chain teeth which are heavier and commonly used with jackets, open-front sweatshirts and cardigans.

The same sewing process is used regardless of whether the zipper teeth are plastic coils or metal chain. What matters in the application process is that the length of the zipper fits into the garment opening, and the zipper is inserted prior to clean finishing the opening’s top and bottom edges.

In this tutorial, you’ll learn how to sew and exposed separating zipper using two finishing techniques:

A regular topstitched finish: this is a faster, easier and a less expensive option.

A faced garment opening finish: this option is higher quality, and involves enclosing the zipper tape and seam edges with a front facing.

How To Sew A Topstitched Exposed Separating Zipper

Leave the neckline and hem edges unfinished until the zipper is attached.

Before aligning the zipper, clean finish the edges of the garment opening individually using the finish of your choice. The easiest (and most casual) technique is an overedge stitch such as zigzag or serging. You can also use binding to enclose the edges for a higher quality finish.

1. Open the zipper all the way and center the left side of the zipper with the left garment opening edge such that the zipper tape corresponds to the seam allowance and the zipper teeth are aligned on top of the seamline as shown.

Insert pins horizontally to keep the zipper tape aligned.

The face sides of both garment and zipper should be touching. If the garment’s opening edge has a ½” seam allowance and the zipper tape is about ½” wide, then the edge of the zipper tape should align with the garment opening edge as shown.

Position the zipper about ½” down from the top neck edge. Its bottom stop should end where the finished hemline is.

2. For extra stability during the stitching process, it may be helpful to hand baste this zipper portion.

3. Using a zipper presser foot, machine stitch the zipper starting from the bottom and moving toward the top. Follow the woven stitch guideline on the zipper tape.

For less of the zipper tape to show in the final application, you can stitch closer to the zipper teeth as desired.

4. After the left side of the zipper is stitched, close the zipper all the way up and lay the zipper flat, face up on the table.

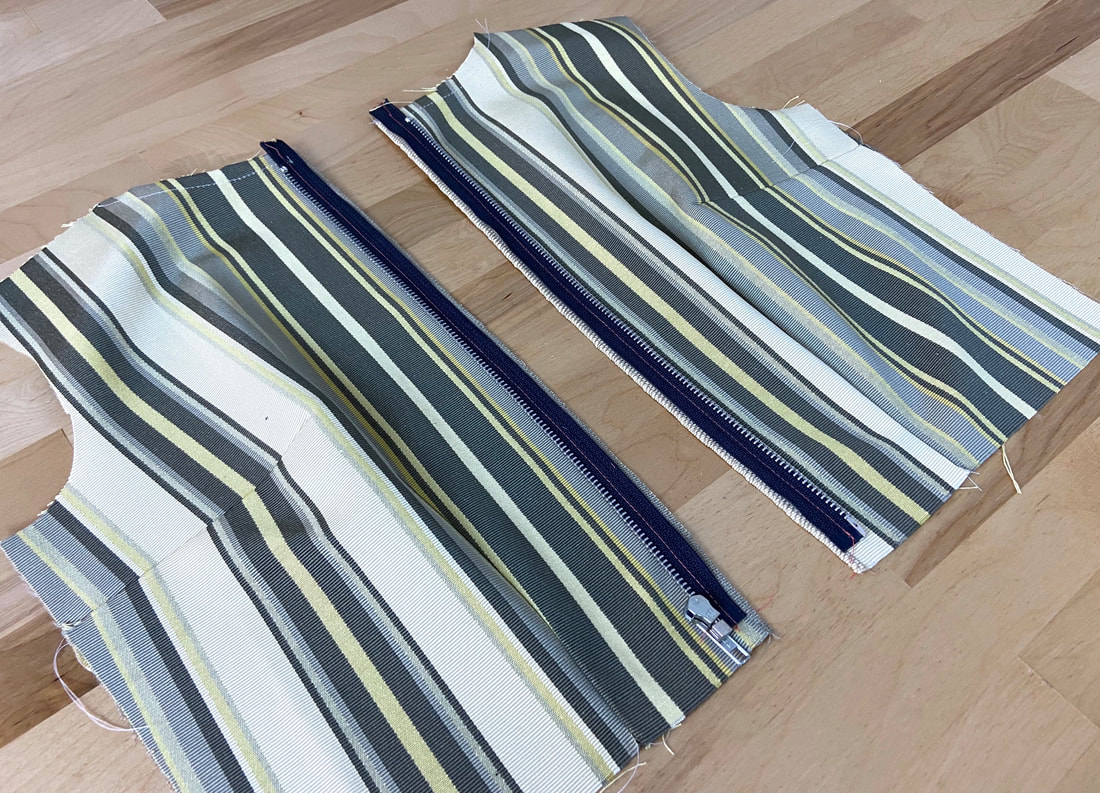

5. Take the right side of the garment and place it face down on top of the zipper such that the garment top (neckline) and bottom (hem) edges align, and the lengthwise garment opening edge aligns with the unstitched zipper tape portion. From the zipper tape side as shown, insert a few pins horizontally through the tape and garment edge.

6. Once the right zipper tape is properly aligned to the right garment edge, open the zipper all the way and separate the two pieces. Insert a few more pins to stabilize the zipper tape to the garment edge. Hand baste if needed.

7. Using a zipper presser foot, machine stitch starting at the bottom and moving toward the top, following the woven stitch guideline on the zipper tape as shown.

Last but not least, iron and topstitch the zippered edges:

8. First, flip the zipper tape and seam allowance edges towards the inside of the garment. Iron the seam fold line from the right side of the zipper application. Repeat on both sides of the garment opening.

9. Using a zipper foot (or regular presser foot, if the zipper teeth are farther away), topstitch on the face of each zipper portion at about 1/8” away from the zipper seam fold as shown.

Repeat the topstitching process on both sides of the garment opening.

When the application is completed and the separating zipper is closed all the way up, both the neckline and hemline edge should align perfectly.

How To Sew A Faced Exposed Separating Zipper

1. Repeat Steps 1-9 described above to attach each separating zipper portion to its corresponding garment opening edge.

Your pattern set should have provided the facing pieces for the garment opening. Conveniently, a front garment facing can often finish both the opening edge and the front neckline edge simultaneously.

You should have two identically-cut facing pieces, the mirror image of each other, corresponding to each opening portion.

2. Make sure both the garment and facing neck edges are staystitched for stability.

More on staystitching in this tutorial:

3. Sew the shoulder seams of both facing and garment. Trim seam allowances halfway down if needed, then iron them open as shown.

4. Keeping the garment on its right side, place the facing right side down, such that all shoulder seams, neckline edges and front opening edges align. The facing and garment face sides should be touching.

At the garment opening, the zipper tape will be sandwiched in between the facing and garment layer.

5. Insert pins horizontally to keep all layers aligned. Hand baste the facing and garment layers together for extra stability. This is especially helpful along the curved edge of the neckline.

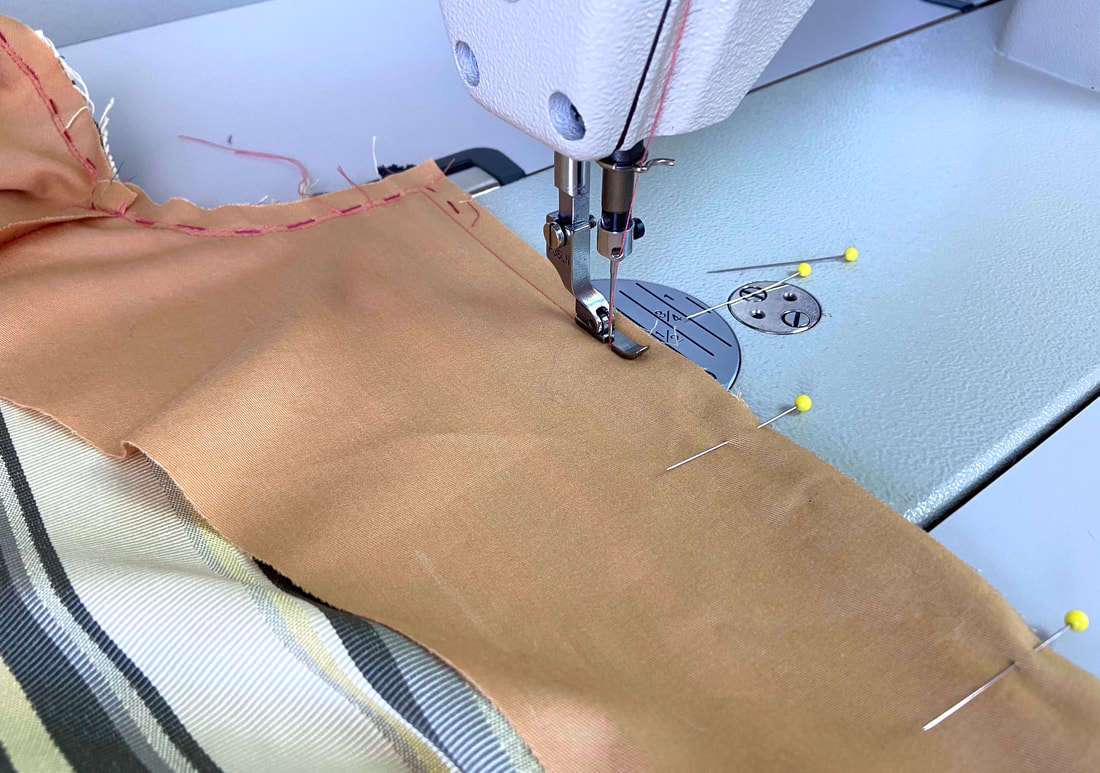

6. Using a zipper foot, stitch at the designated seam allowance, starting at the bottom and moving towards the neckline.

7. When arriving at the neck seamline, pivot the stitch to align the neckline edges with the seam allowance guides on your machine, and stitch for about an inch as shown.

8. Switch to a regular presser foot and stitch along the neckline until you arrive at about 1” from the other garment opening edge.

9. Switch to a zipper presser foot again. Align the needle to the right of the foot plate and stitch through the facing, tape and garment underneath until you arrive at the garment's hem.

At this point, remove any hand basting stitches using a seam ripper.

10. Trim and notch the curved seam allowance edges along the neck edge.

Trim the top corner at each opening edge diagonally to minimize bulk.

11. Extend the facing away from the garment such that all seam allowances, including the zipper tape, point away from the garment and are aligned underneath the facing layer.

12. Understitch through the facing, zipper tape and seam allowance layers underneath, at about 1/8” away from the facing seam as shown. Repeat along the neckline seam.

13. Clean finish the outer facing edges if you haven’t done so already, and flip the facing to the inside of the garment.

Last but not least, iron on top of all finished edges- use a protective cloth if needed.

Follow the steps in this tutorial to learn how to clean finish the hem at each garment opening edge: Sewing Faced Hem Corners