The Importance Of Interfacing When Sewing Facings

A facing is a separate compartment cut to match the exact shape of the garment area housing the faced edge. In order for the faced edge to remain properly structured and stable in the finished garment application, interfacing is used to back either the garment layer or the wrong side of the facing unit. Interfacing stabilizes the area housing the facing compartment, resulting in a flat and more structured finished edge.

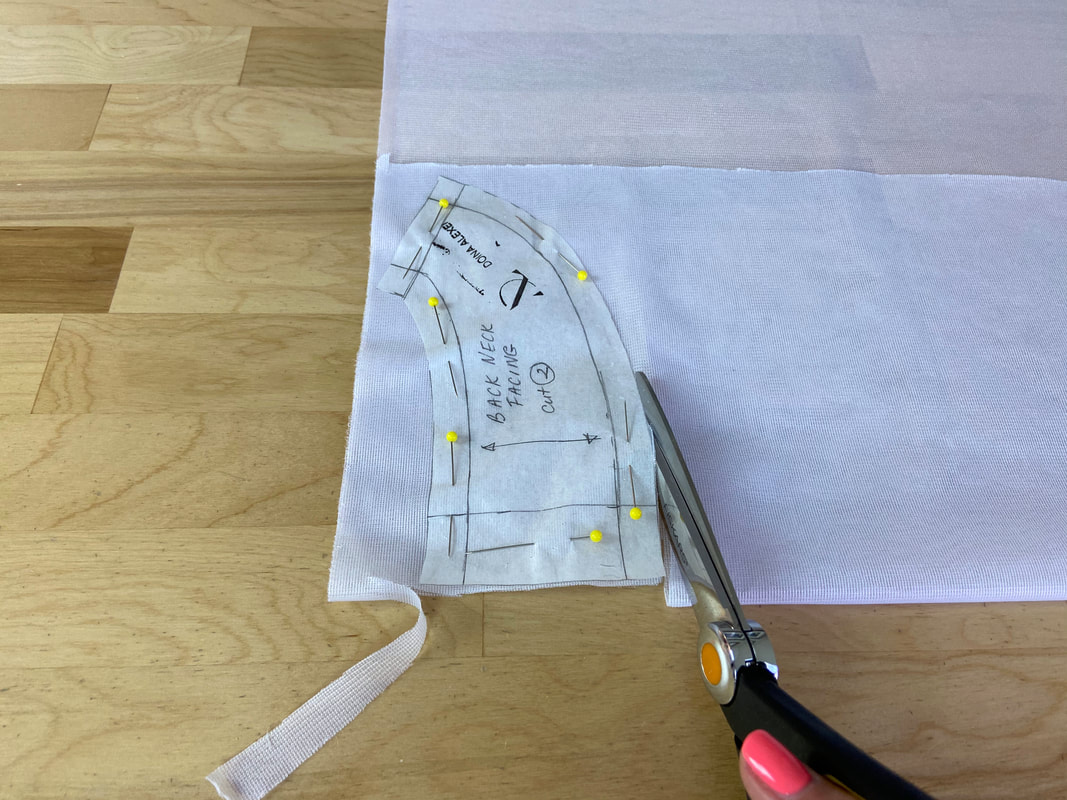

While your pattern set my not include separate patterns for the interfacing, you can use the garment facing patterns to cut the individual interfacing pieces. Once cut, each fusible surface should correspond to the wrong side of the garment area it backs. For that reason, treat the interfacing's fusible side as the "fabric right side" and cut the interfacing pieces in the same alignment as the actual facing pieces.

To minimize bulk and thickness within the finished faced edges, it is best for interfacing not extend into the seam allowance. For best results, you should trim the seam allowance off along all edges prior to fusing the interfacing layers.

The resulting interfacing is then fused within the seamlines, not extending into the seam allowance area. Conventionally, interfacing is added to the wrong side of the garment. However, if your facing is the one requiring more stabilizing or the garment design/fabric is not compatible with interfacing, you can fuse the interfacing to the wrong side of the facing layers instead. The best example in this case is when the garment's edge features gathers or pleating, or it drapes out into a flowey shape that could be compromised by the interfacing's added structure. In these instances, the facing layer (backing these edges) should be interfaced instead.

If the faced edge houses a garment closure, such as a zipper, the interfacing should stop at the seamline and not extend into seam allowance layers housing the closure (as pictured above).