Understanding Armhole Shaped Facings In Dressmaking

A shaped facing is used to enclose armhole raw edges by molding perfectly to the armhole form. A standard facing is usually 2-3 inches wide and constructed such that it takes the exact shape of the area and edge it clean-finishes.

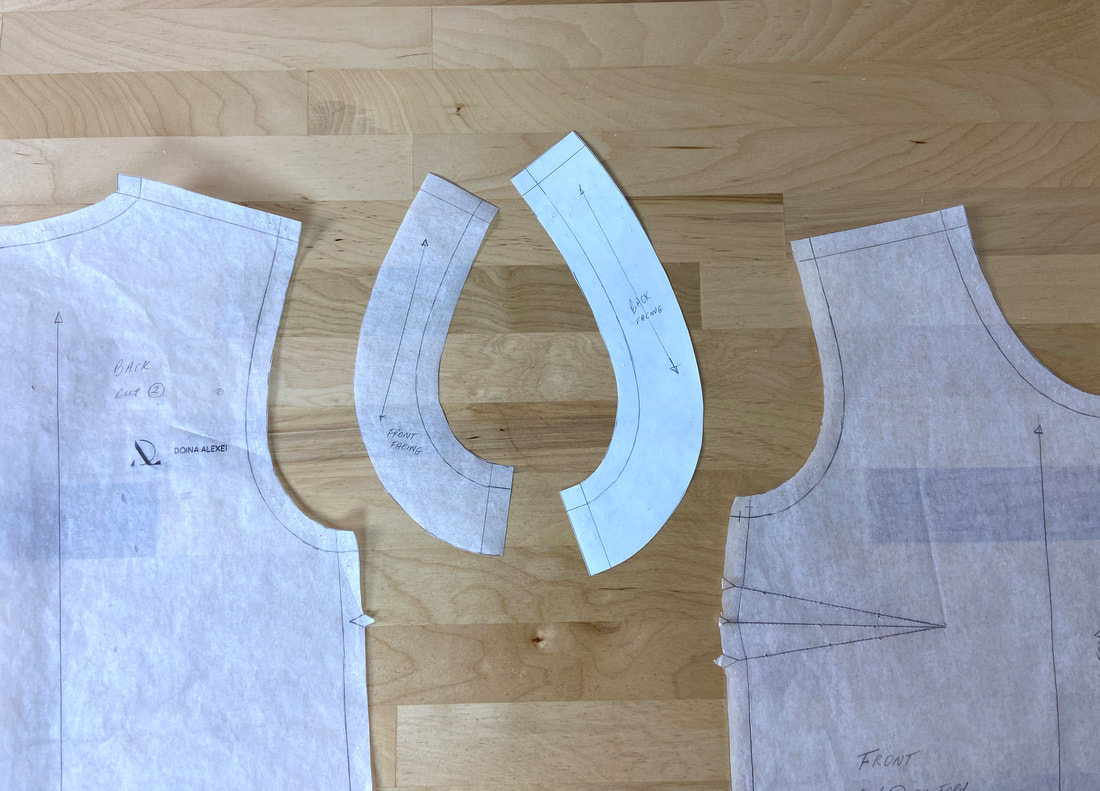

The facing compartment is constructed separately then aligned and stitched to the edge it finishes. The facing's right side is always the mirror image of the garment's face side as pictured above.

The facing compartment is constructed separately then aligned and stitched to the edge it finishes. The facing's right side is always the mirror image of the garment's face side as pictured above.

Given that shaped facings mold to the exact form they clean-finish, they require sewing patterns for a precise cut.

Conventionally, an armhole facing is constructed of two separate pieces each corresponding to the front and respectively, the back armhole edge. Similar to the garment's structure, a standard armhole facing compartment has both a shoulder seam and side seam (underarm). When the facing unit is aligned to the garment's armscye edge, these two seams should match those on the garment perfectly.

In some cases, an armhole facing can be cut as a single piece connected at the shoulder and featuring just one seam at the underarm.

Conventionally, an armhole facing is constructed of two separate pieces each corresponding to the front and respectively, the back armhole edge. Similar to the garment's structure, a standard armhole facing compartment has both a shoulder seam and side seam (underarm). When the facing unit is aligned to the garment's armscye edge, these two seams should match those on the garment perfectly.

In some cases, an armhole facing can be cut as a single piece connected at the shoulder and featuring just one seam at the underarm.

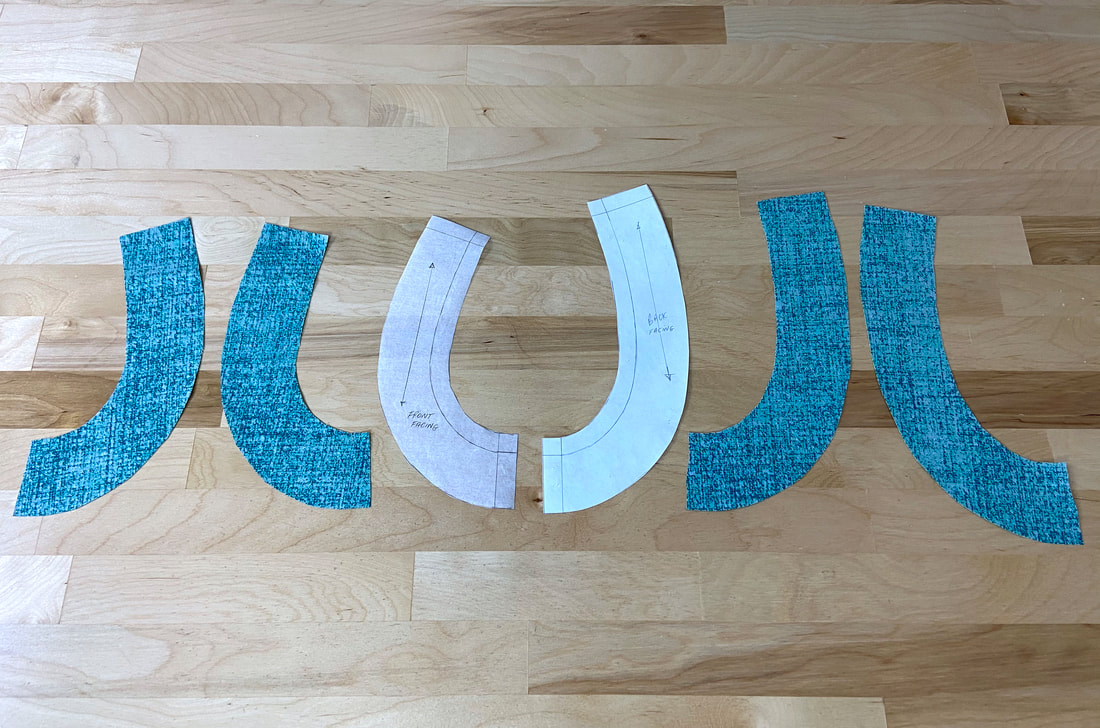

When cutting the facing pieces, you will need two front and respectively, two back facing layers. Each front and corresponding back piece should be the mirror image of each other as shown above. You can naturally accomplish this by folding the fabric layer with right sides touching when cutting two of each (front or back) facing layer.

When finally sewing the facing compartment, the individual seams are treated as you would any conventional garment seam. In this instance, they are are stitched at 1/2" seam allowance and ironed with the seam allowance layers open.

It is also recommended that you clean-finish the outer facing edge prior to aligning and stitching the facing unit to the garment. Doing so will simply provide more comfort during the edge-finishing process as you won't have to manage the entire garment simultaneously.

Once complete, the facing is aligned to the garment's armscye with face sides touching, and all corresponding edges and seamlines aligning. In this position, the two armhole edges are finally stitched together at the designated seam allowance.

It is also recommended that you clean-finish the outer facing edge prior to aligning and stitching the facing unit to the garment. Doing so will simply provide more comfort during the edge-finishing process as you won't have to manage the entire garment simultaneously.

Once complete, the facing is aligned to the garment's armscye with face sides touching, and all corresponding edges and seamlines aligning. In this position, the two armhole edges are finally stitched together at the designated seam allowance.

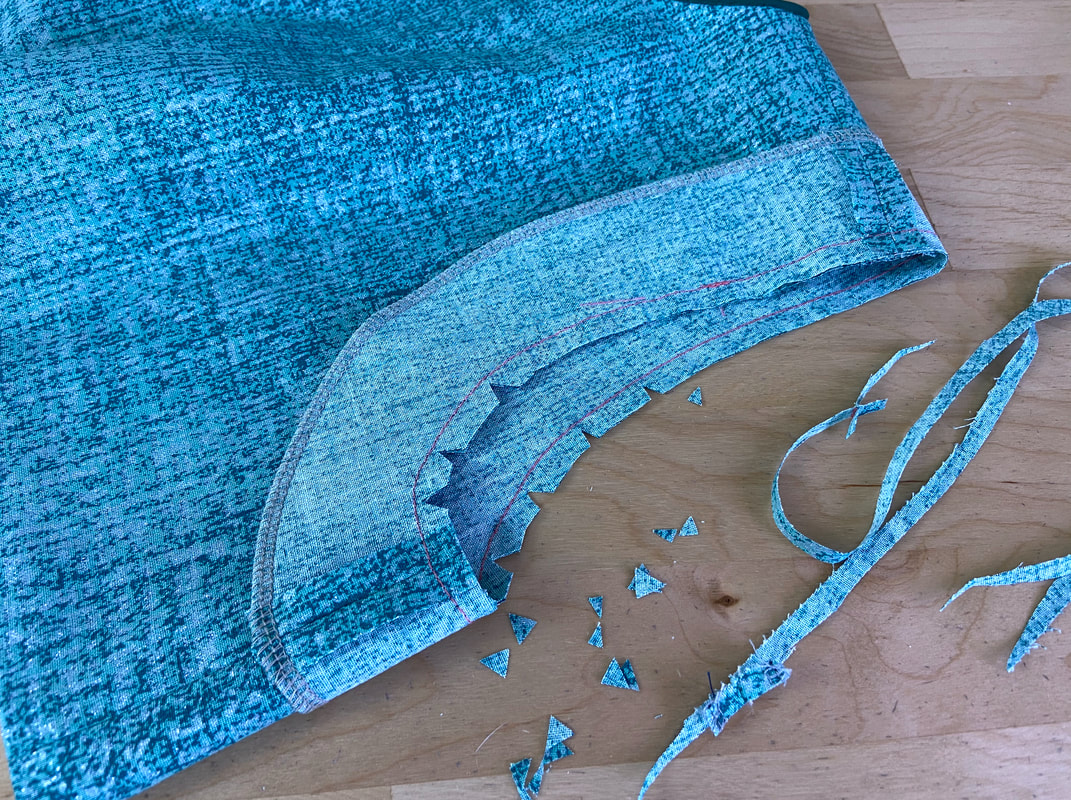

Before flipping the facing layer to the garment's wrong side, it is essential that the seam allowance is trimmed (if necessary), and clipped with wedge notches along the curved portion of the underarm. The facing layer should also be understitched to not only keep it flat but also prevent it from rolling to the outside of the finished garment.

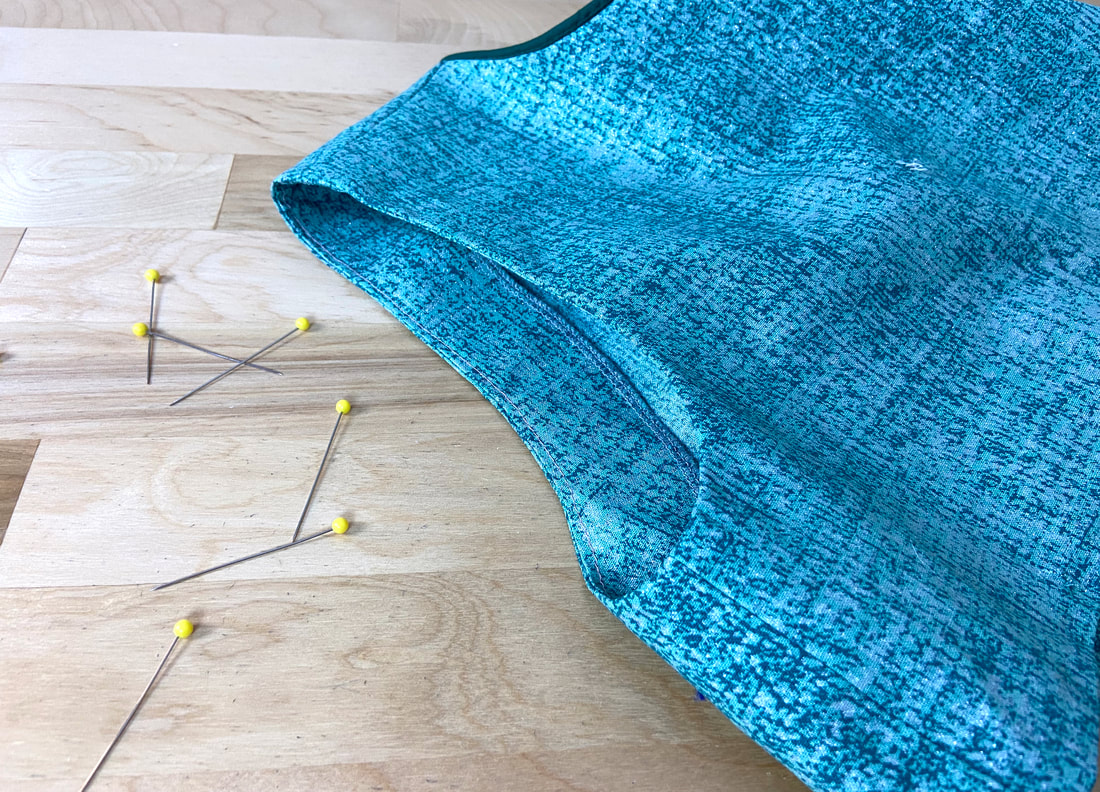

Last but not least, the facing is flipped to the inside of the garment. If cut and constructed correctly, it should lay smooth and completely flat against the wrong side of the garment surface.