What Is A Fly Zipper Shield And How Is It Used In Dressmaking?

A zipper shield plays an important role in a fly-front zipper application. Essentially, the fly shield provides a barrier between skin and zipper ensuring a comfortable, non-irritable finish.

Fly zippers are positioned at the center front of bottoms like trousers, shorts and skirts. Their location corresponds to a more sensitive area on the body which is overall, more perceptive and sensitive to the zipper teeth. Fly-front applications are also conventionally constructed with metal chain zippers which have a heavy duty, rougher structure compared to conventional plastic coil zippers.

Fly zippers are positioned at the center front of bottoms like trousers, shorts and skirts. Their location corresponds to a more sensitive area on the body which is overall, more perceptive and sensitive to the zipper teeth. Fly-front applications are also conventionally constructed with metal chain zippers which have a heavy duty, rougher structure compared to conventional plastic coil zippers.

A fly shield is a double layer compartment stitched to the wrong side of the zipper application to fully cover both the zipper tape and zipper teeth.

Once the shield is attached, non of the zipper components should be visible on the inside of the garment when the zipper is closed. The fly shield itself should be clean-finished along all edges with the exception of the top horizontal edge which is usually stitched into a waistband or another seam.

Once the shield is attached, non of the zipper components should be visible on the inside of the garment when the zipper is closed. The fly shield itself should be clean-finished along all edges with the exception of the top horizontal edge which is usually stitched into a waistband or another seam.

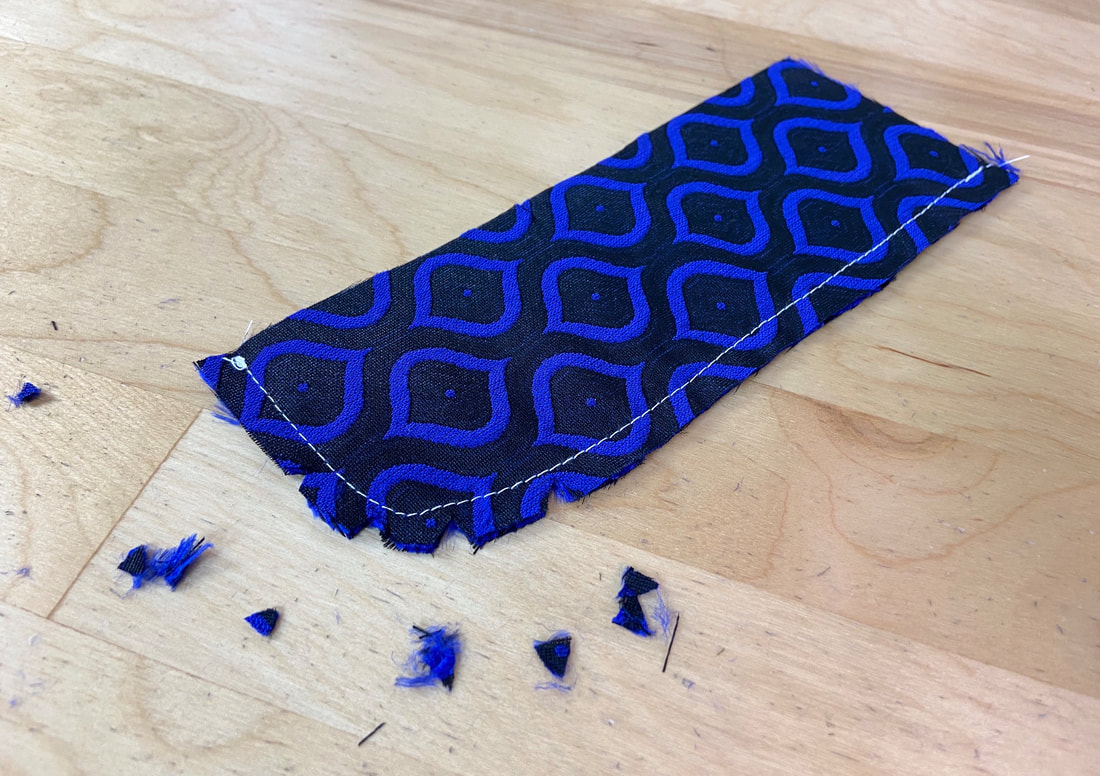

The most conventional fly shield style is a curved-bottom, double-layer compartment featuring a seam along its edge. This style is constructed of two pieces that are aligned with face sides touching and stitched along their curved outer edges.

Before turning the fly shield compartment on its right side (to expose the clean-finished edge), clip wedge notches into the curved portion of the seam allowance as shown above. Doing so ensures that the resulting curved edge is smooth, and bulk/tension free.

Keep in mind that the fly shield should also be clean-finished along its vertical straight edge which, in the application process, is stitched to the garment. The most conventional way to finish these edges is with an overedge stitch like serging or zigzag. It is up to you what technique you choose as long as the resulting finish does not add unnecessary bulk and thickness to the rest of the garment layers.

Attaching the fly shield is the last step in the zipper application process. Keeping the zipper closed, the fly shield is simply placed on top of the exposed zipper teeth/tape (on the garment's wrong side) such that its top unfinished edge aligns with the garment's top horizontal edge, and its straight vertical edge (opposite the curved one) aligns with the garment seam allowance.

If the facing was cut from the same pattern as the fly shield and their shapes are identical, then the fly shield will perfectly overlap the facing underneath, fully sandwiching the zipper in between.

If the facing was cut from the same pattern as the fly shield and their shapes are identical, then the fly shield will perfectly overlap the facing underneath, fully sandwiching the zipper in between.

While the fly shield is aligned from the wrong side of the garment with the zipper closed, it is permanently stitched from the application's face side with the zipper fully open. This final stitch not only connects the fly shield to the garment it also completes the zipper's right portion.