How To Strengthen And Stabilize Pocket Welts In Dressmaking

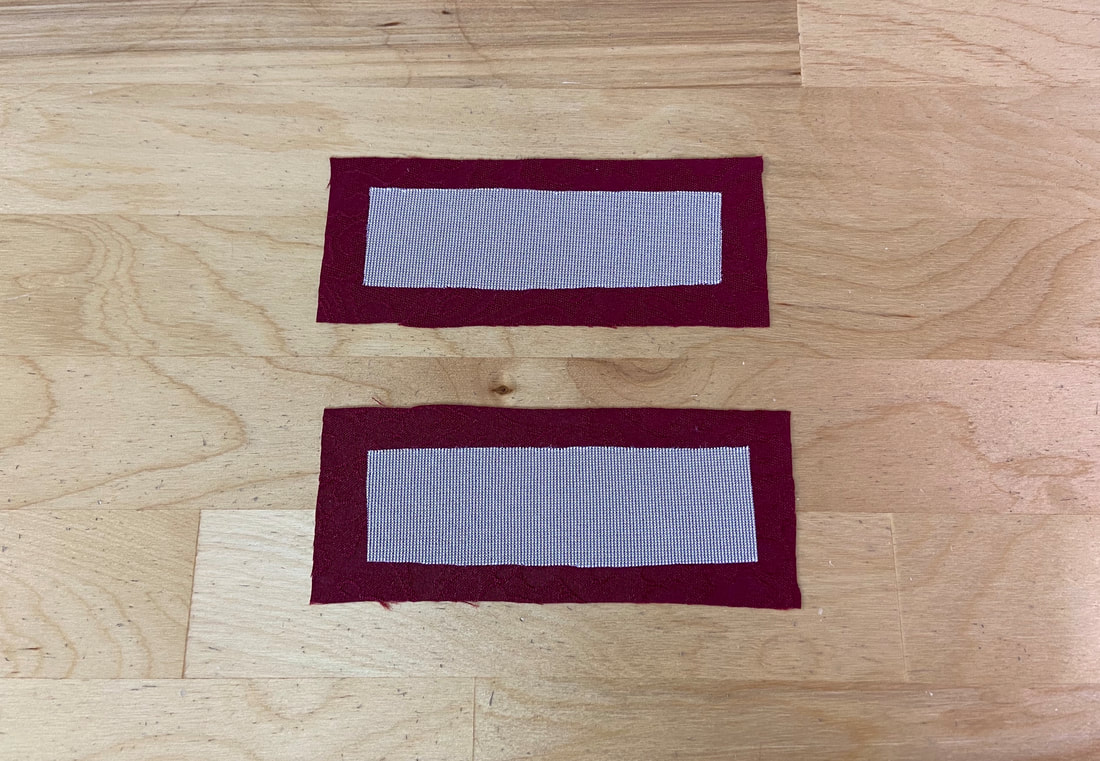

To increase stability and durability, interface pocket welts prior to folding and stitching them to the pocket opening. Use the welt pattern to cut the corresponding interfacing portions. You should have one interfacing piece for each welt.

To minimize bulk and thickness, trim the seam allowances off the interfacing portions prior to bonding them to the wrong side of the welts.

To minimize bulk and thickness, trim the seam allowances off the interfacing portions prior to bonding them to the wrong side of the welts.

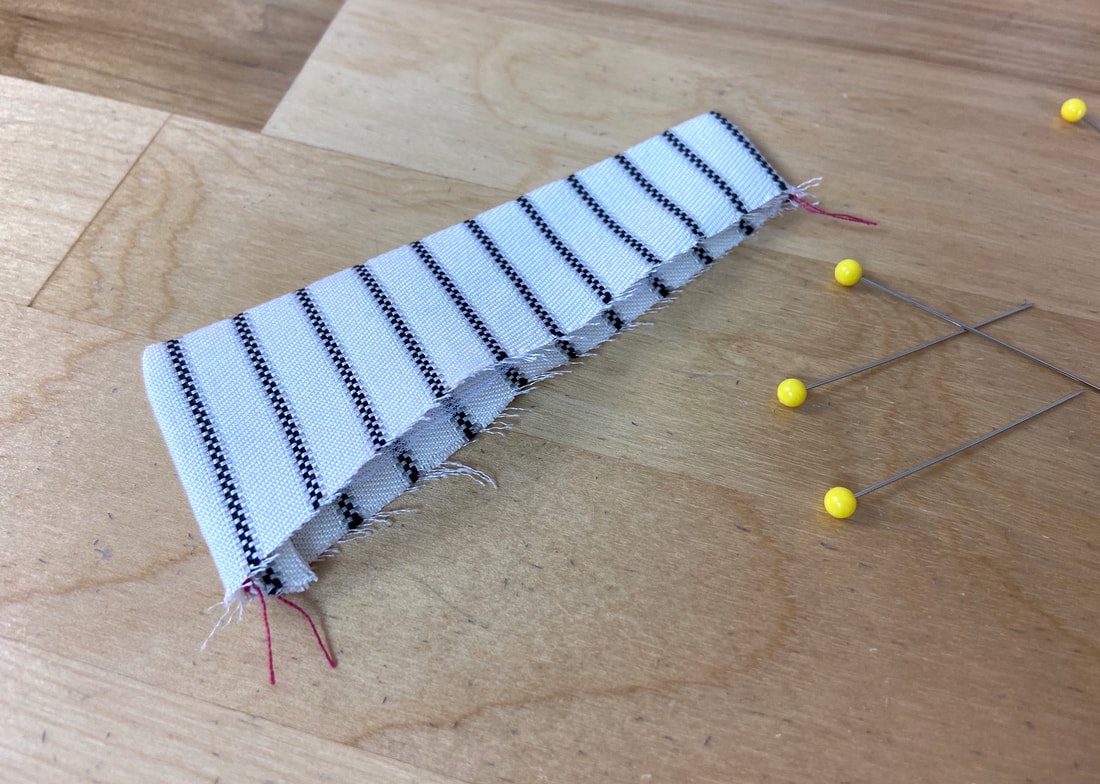

When folding the welt in preparation for pocket construction, the welts are folded with wrong sides touching, hiding the interfacing between the two layers.

The addition of the interfacing adds structure and strength to the welt's folded edge which as a result, will stabilize the entire pocket opening and prevent it from stretching out of shape with prolonged use.

You should interface all welts regardless of their style and construction.

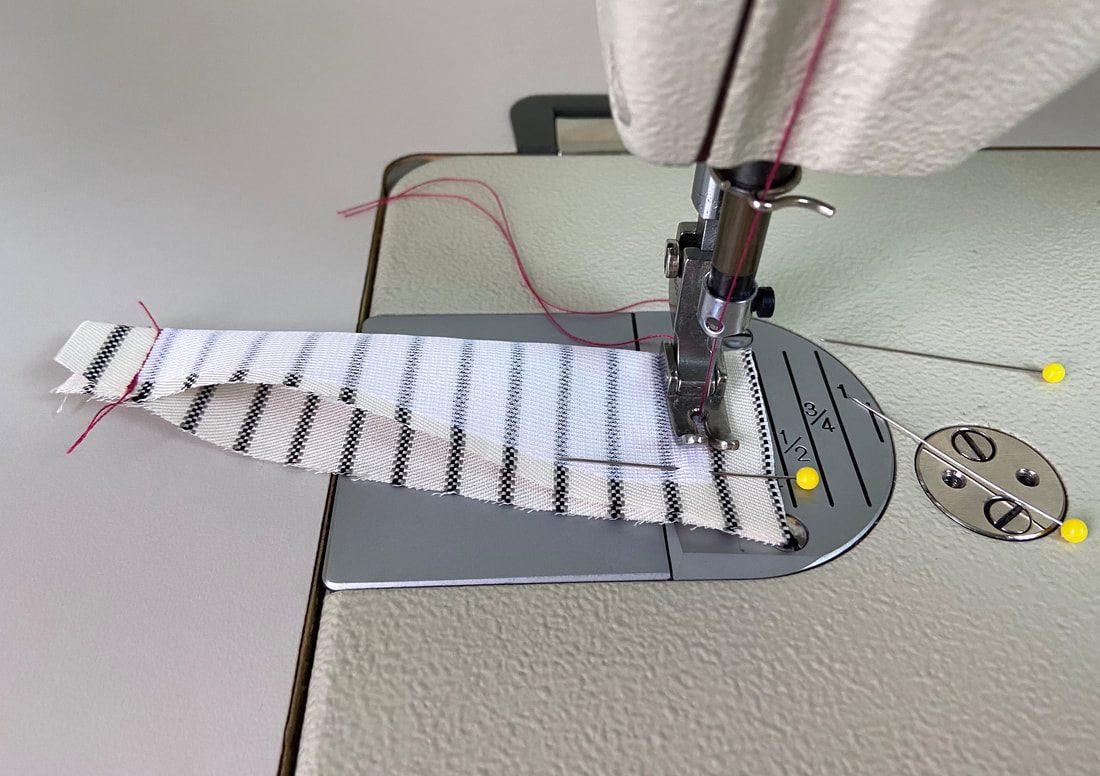

In the slanted welt example above, the welt is constructed similar to a flap. Similar to a regular folded welt, the welt piece is interfaced on its wrong side then the sides are stitched with fabric face sides touching. When flipping the welt on its right side side, the welt maintains its shape and structure.

In the slanted welt example above, the welt is constructed similar to a flap. Similar to a regular folded welt, the welt piece is interfaced on its wrong side then the sides are stitched with fabric face sides touching. When flipping the welt on its right side side, the welt maintains its shape and structure.

In the finished application, interfacing plays an important role in maintain welt shape, structure and strength over long term use.