Three Ways To Finish Lining At The Hem

In the world of sewing lining, the trickiest aspect is sealing the lining layer at the garment's hem. Regardless of your design and lining technique, the lining layer should have enough movement on the wrong side of the garment to not only prevent tension but also stay hidden along the finished hemline edge.

There are three basic techniques you can use to clean-finish lining at the hem- your choice should be made based on garment design, hem length and type of fabric used.

There are three basic techniques you can use to clean-finish lining at the hem- your choice should be made based on garment design, hem length and type of fabric used.

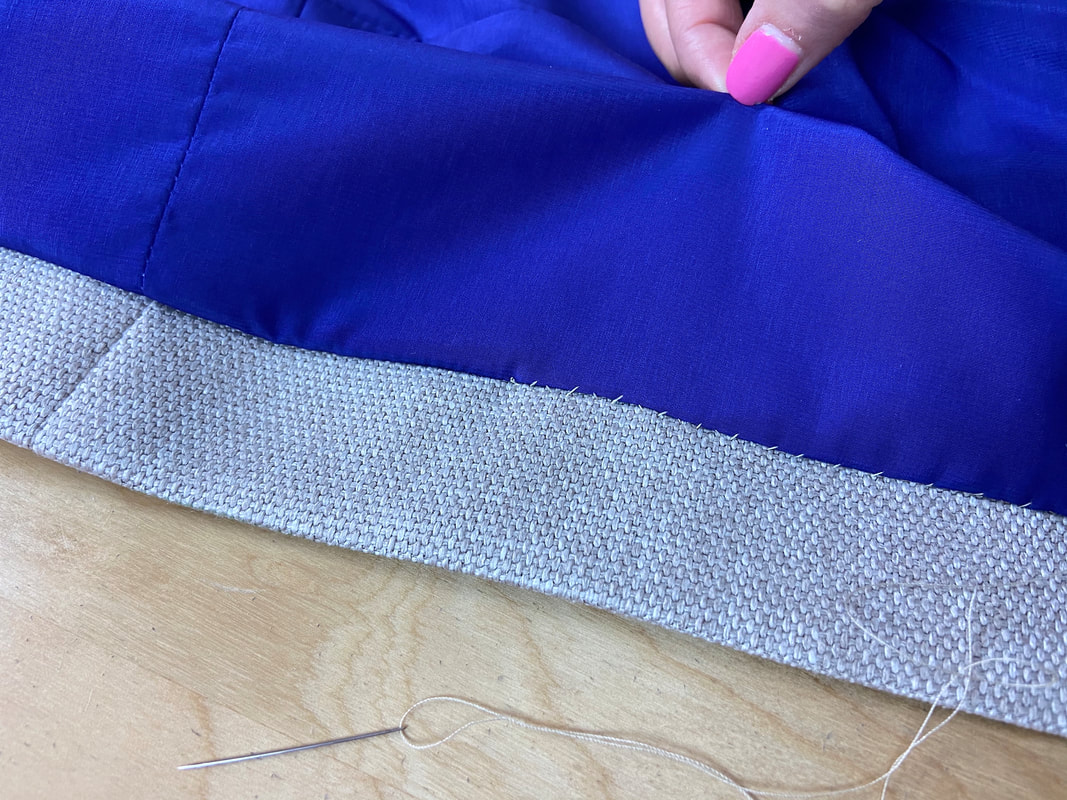

The most basic lining application is completed by hand using a blind stitching application.

Conventionally, a slipstitch is used to connect the lining layer to the garment's hem allowance layer such that no stitching is visible on the face of the garment. This is perhaps the easier application for sewing beginners since the alignment process is more straightforward and easy to follow.

Conventionally, a slipstitch is used to connect the lining layer to the garment's hem allowance layer such that no stitching is visible on the face of the garment. This is perhaps the easier application for sewing beginners since the alignment process is more straightforward and easy to follow.

When the lining layer is folded down in its final, natural position, the hand stitching is hidden underneath the folded layers for a stitch-free, clean finish.

A faster way to connect the lining layer to the garment is with a simple machine stitch. This technique can sometimes feel confusing to sewing beginners. However, once you get the hang of it, it is much faster than the hand-applied version.

In the application process, the lining's hem allowance edge is aligned with that of the garment with face sides touching. It is easiest to align each side of the hemline one at a time leaving a 5"-6" gap in between. Once stitched, this gap will help you flip the the garment layers to their right side.

In the application process, the lining's hem allowance edge is aligned with that of the garment with face sides touching. It is easiest to align each side of the hemline one at a time leaving a 5"-6" gap in between. Once stitched, this gap will help you flip the the garment layers to their right side.

The open gap will need to be sealed/closed to finalize the lining application.

To complete, the lining is slipsticthed to the hem allowance layer underneath. There should be no visible stitching on the face of the garment. In its natural position, the lining folds over the hem allowance, hiding the stitch underneath.

Lining can also be finished in a free-hanging style. With this technique, the lining and garment hems are finished separately thus hanging separately from one another.

This technique is often used with lightweight, drapey garments like loose tops and dresses.

Generally, a free-hanging lining provides more movement and prevents tension in the finished hem.

This technique is often used with lightweight, drapey garments like loose tops and dresses.

Generally, a free-hanging lining provides more movement and prevents tension in the finished hem.

To keep the lining in perfect alignment with the garment layer, a french tack is used at the side seams. French tacks can be constructed by hand using a blanket-like stitch that forms a chain. This chain should be about 1"-1.5" long to allow the lining enough movement and flexibility while also keeping it properly aligned.