What Is The Difference Between Hem Tape And Fusible Webbing?

If you are looking to experiment with no-sew finishes, you may have come across two very common no-sew hemming techniques: hem tape and fusible webbing. Both of these can be used to finish a garment's hem.

While the result is quite durable and withstands washing in most cases, it does not always measure up to the good ol' stitch.

Here are a few main differences between hem tape and fusible webbing:

While the result is quite durable and withstands washing in most cases, it does not always measure up to the good ol' stitch.

Here are a few main differences between hem tape and fusible webbing:

Hem tape is a pre-cut adhesive strip available in a few different widths to accommodate your individual project. You can find hem tape at your local craft/fabric stores on pre-packaged rolls.

Most hem tapes are made from a specialized solid adhesive that when heated with an iron, melts and bonds fabric layers together. Hem tape works well with most fabrics including those featuring natural contents like cotton, silk, linen, and most synthetics.

Most hem tapes are made from a specialized solid adhesive that when heated with an iron, melts and bonds fabric layers together. Hem tape works well with most fabrics including those featuring natural contents like cotton, silk, linen, and most synthetics.

You can find it in a regular or heavy duty weight based your particular application. While thinner options provide a lighter finish, hem tapes tend to add some stiffness and structure to a garment's hem regardless of weight. It is important to consider whether the addition of the tape will compromise the garment's drape and fit.

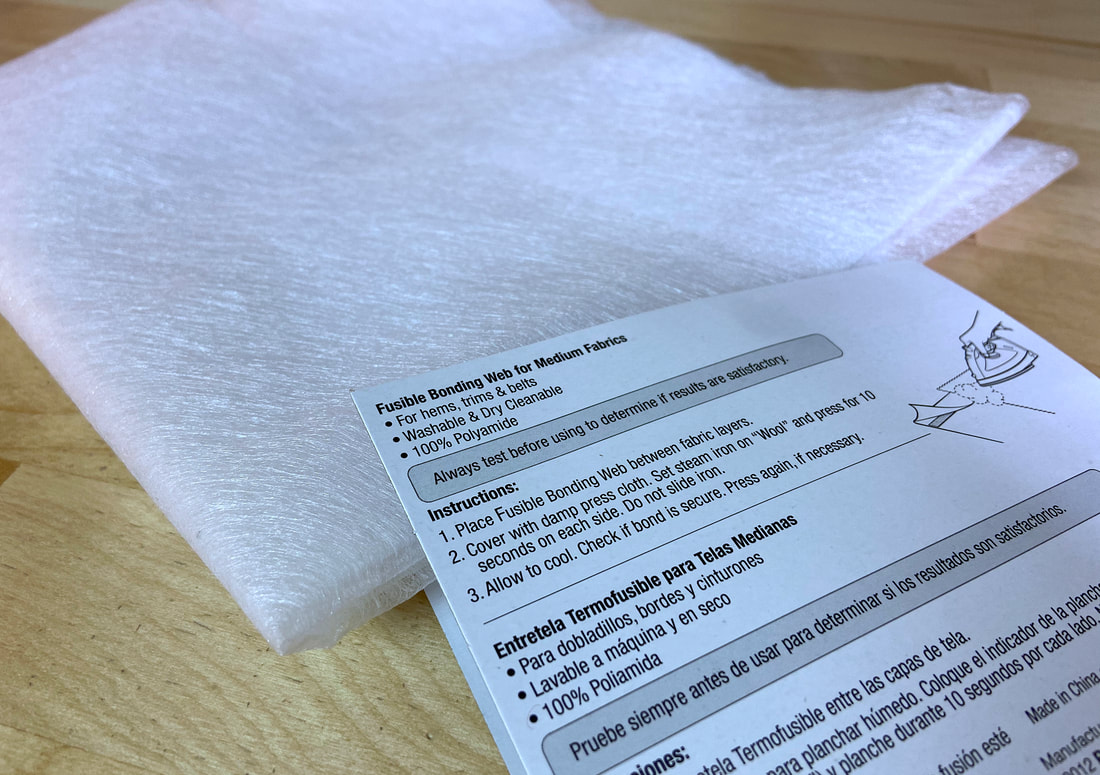

Fusible webbing tends to be lighter than conventional hem tapes. As opposed to hem tape which comes readily pre-cut in the width of your choice, fusible webbing can be purchased by the yard or packaged in a pre-cut portion.

The structure of fusible webbing resembles that of interfacing. It is built from polyamide fiber forming a light, transparent structure. Similar to hem tape, fusible webbing bonds two fabric layers together with the addition of iron heat.

The beauty of fusible webbing is that you can cut it as wide as needed based on the particular project. This is especially useful when finishing wide hem allowance, or when using it to bond larger surface areas.

The structure of fusible webbing resembles that of interfacing. It is built from polyamide fiber forming a light, transparent structure. Similar to hem tape, fusible webbing bonds two fabric layers together with the addition of iron heat.

The beauty of fusible webbing is that you can cut it as wide as needed based on the particular project. This is especially useful when finishing wide hem allowance, or when using it to bond larger surface areas.

Regardless of whether you choose hem tape or fusible webbing in your final hemming application, it is important to follow the bonding instructions accurately in order to achieve the most optimal, durable finish.

As always, test a scrap of your fabric prior to use as the adhesive can often bleed through to the fabric's face side.

In the case of heavily decorative or highly textured fabrics, you may find that no-sew bonding techniques will not work as efficiently due to the fabrics' heat sensitivity or the adhesive not properly bonding to their highly textured surface.

As always, test a scrap of your fabric prior to use as the adhesive can often bleed through to the fabric's face side.

In the case of heavily decorative or highly textured fabrics, you may find that no-sew bonding techniques will not work as efficiently due to the fabrics' heat sensitivity or the adhesive not properly bonding to their highly textured surface.